The Evolution and Benefits of Automatic Cut to Length Machines

In the modern manufacturing landscape, efficiency and precision are paramount. Industries that rely on cut materials, such as metal fabrication, woodworking, and plastics, have significant advantages when they incorporate automatic cut to length machines into their production processes. These machines represent a fusion of advanced engineering and cutting-edge technology, designed to streamline operations and enhance product quality.

Understanding Automatic Cut to Length Machines

Automatic cut to length machines are specialized devices used to cut large rolls or sheets of material into predefined lengths. Unlike traditional manual cutting methods, these machines operate using automated systems, allowing for consistent quality and reduced human error. Typically, they are equipped with sensors and software that enable precise measurement, ensuring that every cut is made to the exact specifications required by the production process.

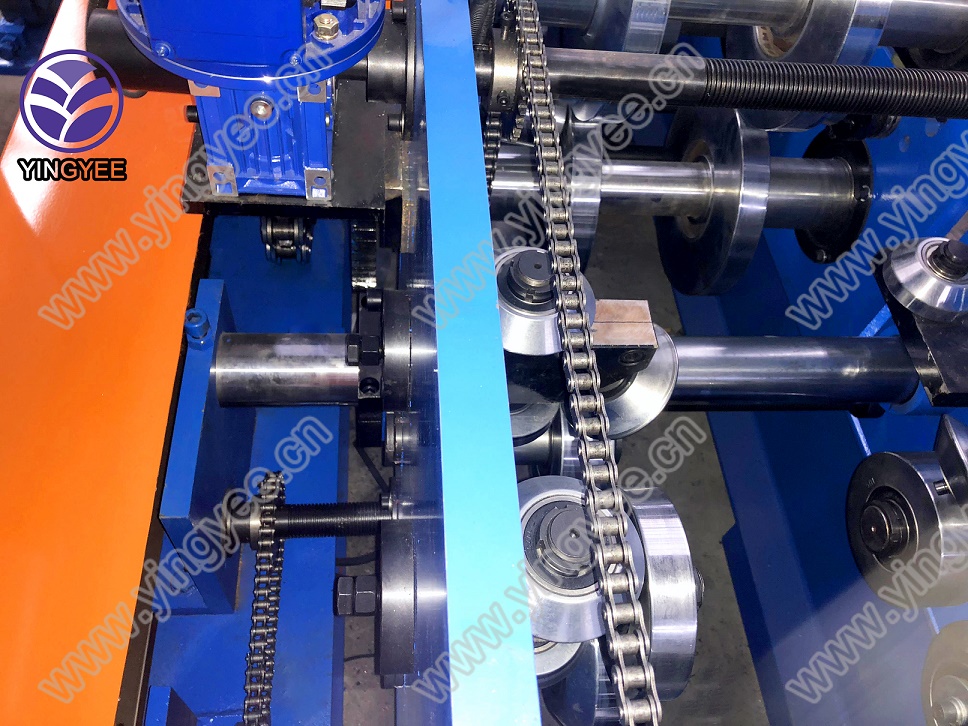

The functional principle of an automatic cut to length machine involves several key components a feed system for moving the material, a cutting mechanism, and a control system that manages the operation. The feed system pulls the material from a roll or stack while the cutting mechanism slices the material to the desired lengths. The control system allows operators to input length specifications and manage production schedules, resulting in a seamlessly coordinated workflow.

Advantages of Using Automatic Cut to Length Machines

1. Increased Efficiency One of the primary benefits of automatic cut to length machines is their ability to operate continuously without the need for frequent interruptions. This leads to higher throughput and helps manufacturers meet tight deadlines without compromising quality.

2. Improved Precision Automation ensures high levels of accuracy, significantly reducing the chances of errors that are more common in manual cutting processes. This precision translates into better-fitting components and less wasted material, ultimately enhancing profitability.

3. Cost Savings Though the initial investment in an automatic cut to length machine can be significant, the long-term savings are substantial. By minimizing waste and reducing labor costs associated with manual cutting operations, companies can achieve a quicker return on investment.

4. Flexibility Many modern machines are designed to handle various materials and accommodate quick changes in cutting length. This flexibility allows manufacturers to adapt to different projects without extensive modifications to their equipment.

5. Safety Improvements Automation reduces the need for manual handling of cutting tools, which can pose safety risks. By minimizing human involvement, the likelihood of workplace injuries decreases, fostering a safer working environment.

Applications in Various Industries

Automatic cut to length machines are utilized across various sectors, including

- Metal Fabrication In industries that work with metal sheets and coils, these machines provide the precision needed for components in construction, automotive, and aerospace.

- Woodworking For furniture manufacturers, accurate cuts are essential in producing high-quality products that fit together seamlessly.

- Plastics Manufacturing The packaging and consumer goods industries frequently use cut to length machines to create uniform components from plastic sheets and films.

Conclusion

As industries continue to seek ways to enhance efficiency and productivity, automatic cut to length machines have emerged as vital tools in manufacturing. Their ability to deliver precision, reduce waste, and enhance safety makes them an attractive investment for companies aiming to thrive in a competitive market. Embracing this technology not only streamlines production processes but also improves the overall quality of the end products, exemplifying the seamless integration of technology in modern manufacturing practices. As advancements continue, the capabilities of these machines are likely to expand, further cementing their role in the future of production.