The Automatic Cut to Length Line Revolutionizing Manufacturing Efficiency

In the fast-paced world of manufacturing, efficiency and precision are critical to maintaining competitiveness and ensuring product quality. One of the innovations that have emerged to enhance production processes is the Automatic Cut to Length Line. This sophisticated machinery streamlines the cutting process, allowing manufacturers to achieve high accuracy while minimizing waste and labor costs. This article delves into how an Automatic Cut to Length Line operates, its benefits, and its applications across various industries.

Understanding the Technology

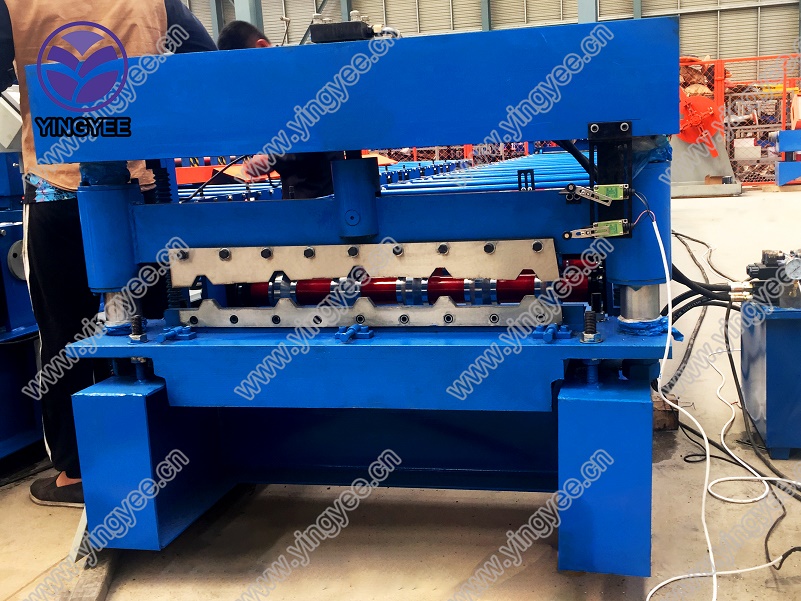

An Automatic Cut to Length Line typically consists of several key components, including a reel stand, uncoiler, leveler, shear or cut-to-length mechanism, and a stacking unit. The process begins when the raw material, usually in the form of coils, is fed into the system. The uncoiler unwinds the coil, allowing the material to be pulled through the leveler, which eliminates any defects from the material’s surface.

Once leveled, the material is accurately fed into the shear where it is cut to the desired lengths based on pre-set specifications. Advanced sensors and control systems ensure that each cut is made with precision, reducing the occurrence of errors. Finally, the stacked cut pieces are organized for easy handling or further processing. This seamless integration of technologies reduces manual interventions, resulting in a highly efficient cutting process.

Benefits of Automatic Cut to Length Lines

1. Increased Efficiency One of the most significant advantages of an Automatic Cut to Length Line is the productivity boost it offers. By automating the cutting process, manufacturers can significantly reduce production time. This allows for greater output and the ability to meet tight deadlines without compromising on quality.

2. Enhanced Precision Human error is a common issue in manual cutting processes. The high degree of automation in an Automatic Cut to Length Line minimizes such errors, ensuring that each piece meets exact specifications. This precision is crucial in industries such as automotive and aerospace, where component dimensions must adhere to strict tolerances.

3. Reduced Material Waste The accuracy of the cutting process means less material wastage. By cutting only what is necessary, companies can lower their material costs and contribute to sustainable manufacturing practices.

4. Versatility Automatic Cut to Length Lines can handle various materials, including metals, plastics, and composite materials. They can also be configured to produce different lengths and thicknesses, making them suitable for diverse manufacturing needs and industries.

5. Lower Labor Costs By automating the cutting process, companies can reduce the number of workers needed on the production line, thus lowering labor costs. This does not necessarily mean a reduction in workforce; employees can be redeployed to focus on value-added tasks, enhancing overall operational efficiency.

Applications Across Industries

The applications of Automatic Cut to Length Lines are vast and varied. In the metals industry, these lines are often used to cut steel and aluminum sheets or strips for subsequent processing or delivery. Meanwhile, in the automotive sector, they ensure that components are cut to precise dimensions for assembly.

The construction industry benefits from Automatic Cut to Length Lines through the production of prefabricated building materials such as cladding and panels. Additionally, the aerospace industry utilizes these lines for cutting lightweight composite materials essential for aircraft manufacturing.

Conclusion

The Automatic Cut to Length Line represents a paradigm shift in manufacturing, combining technology, efficiency, and precision. By investing in such advanced equipment, manufacturers can not only enhance their productivity but also improve product quality and reduce costs. As industries continue to embrace automation, the importance of systems like the Automatic Cut to Length Line will only continue to grow, paving the way for a more efficient and sustainable future in manufacturing.