The Revolutionary Automatic Cable Tray Roll Forming Machine

In the ever-evolving world of manufacturing, automation has brought about significant changes that enhance efficiency and productivity. One of the standout innovations in this domain is the automatic cable tray roll forming machine. This sophisticated equipment is designed to produce cable trays, which are essential components in electrical installations. These trays provide structural support and protection for electrical wiring and networking cables. With the increasing demand for efficient electrical systems in various industries, the importance of advanced manufacturing processes cannot be overstated.

Understanding Cable Trays

Cable trays are used to manage wire and cable systems, ensuring that they are organized, protected, and accessible. They come in various materials such as steel, aluminum, and fiberglass, and are available in different configurations and sizes. The choice of a cable tray depends on the application, location, and environmental factors. The introduction of automatic cable tray roll forming machines addresses several challenges faced in traditional manufacturing methods, including consistency, speed, and labor costs.

The Functionality of a Roll Forming Machine

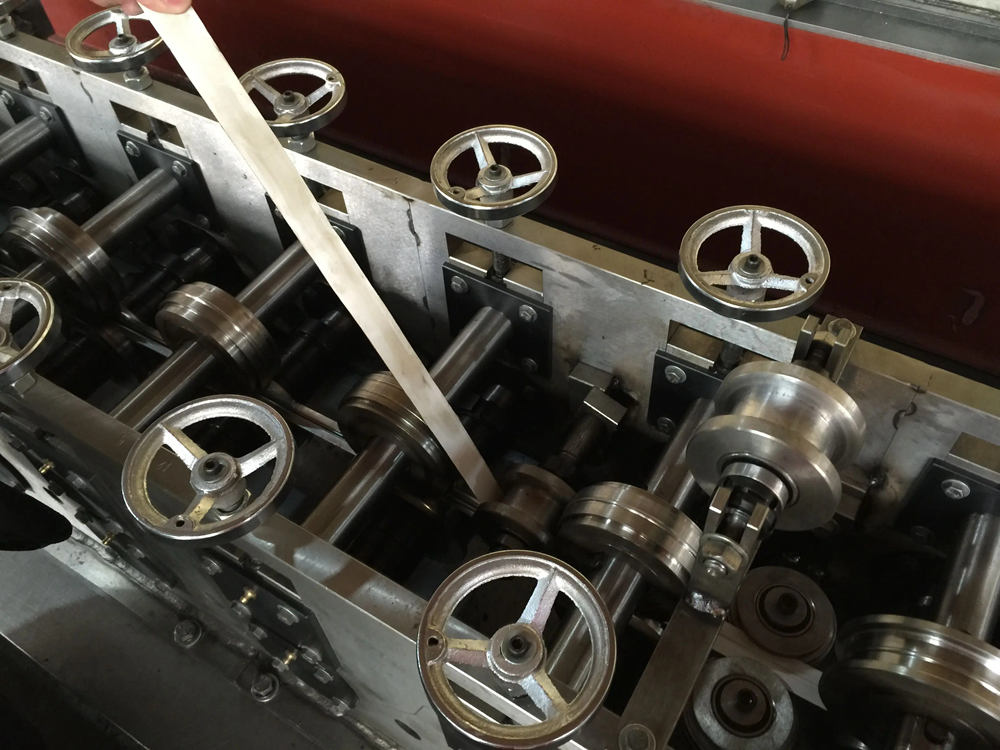

A roll forming machine utilizes a series of rollers to progressively shape a continuous strip of metal into specific profiles without the need for cutting or welding. The automatic cable tray roll forming machine automates this process, greatly enhancing efficiency. The operation begins with feeding raw material, typically a coil of sheet metal, into the machine. As the material passes through the rollers, it is shaped into the desired cable tray profile.

This automation not only reduces the time required for production but also minimizes material wastage, a crucial aspect of manufacturing sustainability

. Additionally, the machine can be programmed to produce various tray sizes and designs, making it a versatile tool in modern manufacturing.Key Features and Advantages

1. Increased Efficiency One of the primary benefits of automatic cable tray roll forming machines is their ability to operate continuously and produce high volumes of products. This continuous operation significantly cuts down on labor costs and time, allowing businesses to meet the growing demands of the market promptly.

2. Precision and Consistency These machines ensure uniformity in product dimensions, which is vital for the interoperability of electrical systems. The precision of automated processes minimizes human error, ensuring that each cable tray meets the specified standards.

3. Customization Modern automatic cable tray roll forming machines can be easily adjusted to produce different tray designs and sizes, accommodating custom orders without significant downtime. This adaptability is critical in today’s rapidly changing marketplace.

4. Cost-Effectiveness While the initial investment in an automatic roll forming machine may be substantial, the long-term savings achieved through increased productivity and reduced labor costs make it a wise financial decision. Additionally, the reduction in waste and the ability to use various materials further enhance cost-effectiveness.

5. Enhanced Safety Features With the automation of the manufacturing process, the risk of workplace injuries associated with manual handling and assembly is minimized. These machines are often fitted with safety features to protect operators and ensure a safer working environment.

Conclusion

The automatic cable tray roll forming machine exemplifies the advancement of technology in manufacturing. As industries continue to evolve and demand for more efficient solutions increases, the role of such innovative machines will undoubtedly become more prominent. Businesses that adopt these technologies can expect not only enhanced productivity but also improved product quality and cost savings.

In summary, the automatic cable tray roll forming machine is a game-changer for manufacturers in the electrical sector. It provides an efficient, accurate, and flexible solution for producing essential cable management systems. As the trend towards automation continues, we can anticipate even greater advancements in machinery that will shape the future of manufacturing and electrical infrastructure. Embracing these innovations is vital for businesses looking to maintain a competitive edge in an increasingly demanding industry.