Automatic Adjust C Z-Purlin Sizes Roll Forming Machine

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One of the critical components in steel structure construction is the purlin, and among the most innovative solutions for producing purlins is the Automatic Adjust C Z-Purlin Sizes Roll Forming Machine. This advanced piece of machinery revolutionizes the way purlins are manufactured, offering numerous advantages over traditional methods.

Understanding C and Z Purlins

Before diving into the specifics of the roll forming machine, it is essential to understand what C and Z purlins are. C and Z purlins are horizontal structural elements used in buildings, typically as support for roof and wall panels. Their names derive from their respective shapes, with the C shaped purlins offering good support capabilities, while Z shaped purlins provide increased strength and span capabilities.

These purlins are vital components in the construction of warehouses, factories, and sheds, where they provide structural stability and support. The flexibility to adjust their sizes according to building requirements makes them even more desirable in construction projects.

The Role of Roll Forming Machines

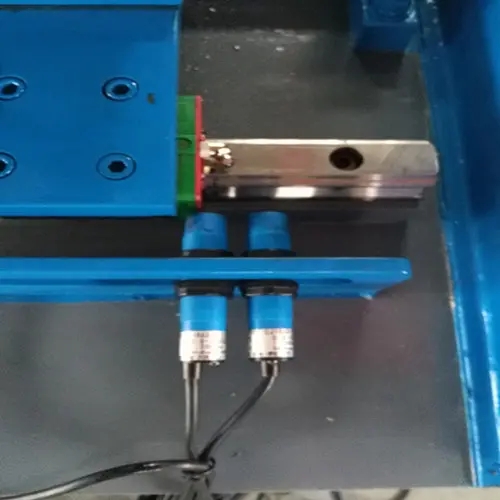

Roll forming is a continuous process where metal strips are fed through a series of rollers to create a desired cross-sectional profile. The Automatic Adjust C Z-Purlin Sizes Roll Forming Machine extends this principle, allowing for the automatic adjustment of purlin sizes without the need for manual intervention. This feature not only enhances efficiency but also significantly reduces production time and labor costs.

Key Features of the Automatic Adjust Roll Forming Machine

1. Automated Size Adjustment One of the most significant advantages of this machinery is its ability to automatically adjust the size of the purlins it produces. Through advanced computer controls, operators can input the required dimensions, and the machine adjusts its rollers accordingly. This flexibility allows for quick changes between different sizes, making it ideal for projects with varying specifications.

2. High Production Efficiency The roll forming machine is designed for high-speed production, allowing for large quantities of purlins to be manufactured in a short period. This efficiency is enhanced by the machine's capability to operate continuously, reducing downtime.

3. Precision Engineering With automated adjustments, the machine consistently produces purlins that meet strict engineering tolerances. The precision in dimensions reduces material waste and ensures that the end products fit perfectly into the building framework.

4. User-Friendly Interface Modern roll forming machines are equipped with intuitive control panels that simplify operation. Operators can easily monitor production and make adjustments, ensuring that the machine runs smoothly and efficiently.

5. Robust Construction and Durability Given the nature of its work, the roll forming machine is constructed from high-quality materials, making it durable and capable of withstanding rigorous operational demands.

Benefits to the Construction Industry

The implementation of the Automatic Adjust C Z-Purlin Sizes Roll Forming Machine has numerous benefits for the construction industry. First and foremost, it enhances production efficiency, allowing contractors to complete projects on time and within budget. The reduction in manual labor not only cuts costs but also minimizes human error, leading to higher quality products.

Furthermore, the ability to produce various sizes on-demand means that businesses can respond more effectively to market trends and project requirements. This flexibility allows for a more dynamic approach to manufacturing and construction, facilitating faster project turnarounds.

Conclusion

The Automatic Adjust C Z-Purlin Sizes Roll Forming Machine is a testament to the advancements in manufacturing technology. It combines efficiency, precision, and flexibility, catering to the evolving needs of the construction industry. As businesses continue to seek ways to optimize production and reduce costs, machinery like this will prove invaluable. By streamlining the process of purlin production, it helps to elevate the standards of modern construction projects, paving the way for quicker and more robust building practices. As we move forward, it is clear that such innovations will play a crucial role in the future of construction and structural engineering.