The Evolution and Benefits of C/Z Purlin Automatic Lines

In modern construction and manufacturing, efficiency and precision are paramount. One of the innovations that has significantly transformed the structural framework of buildings is the C/Z purlin automatic line. This technology not only optimizes production but also enhances the quality of purlins, which are crucial components in the framework of various structures.

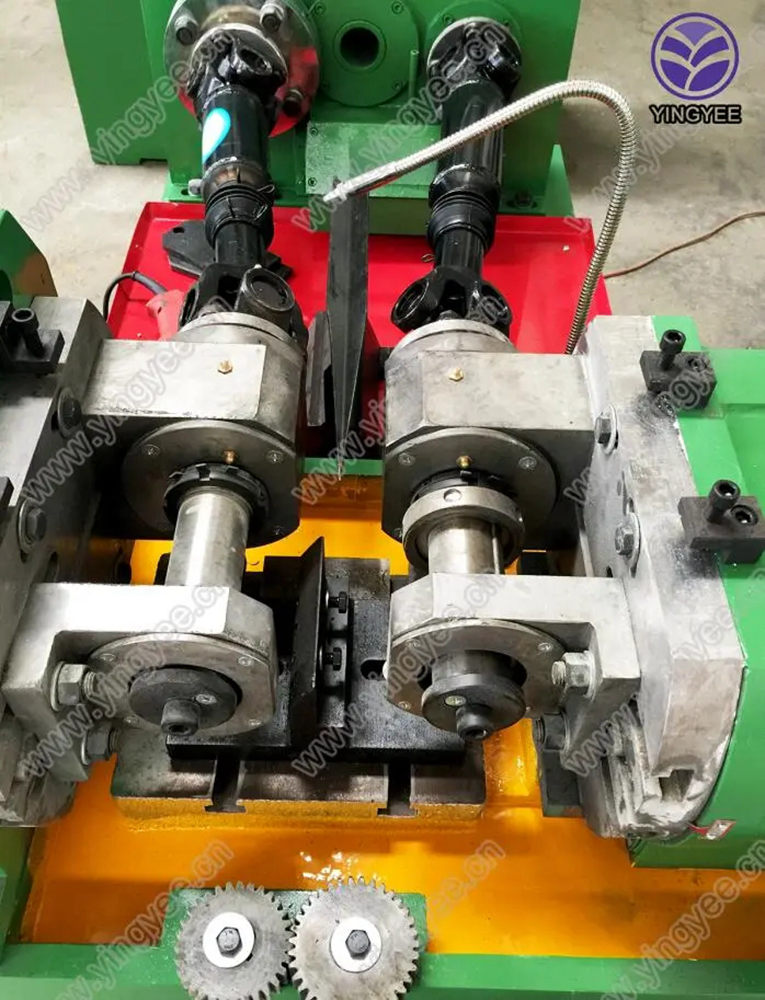

C and Z purlins are cold-formed sections used in steel construction. They serve as horizontal supports for roofs and walls, providing essential structural support. Traditionally, the manufacturing process for purlins involved manual labor, leading to inconsistencies in product quality and production speed. The advent of automatic lines for producing C/Z purlins marks a revolutionary shift in how these essential building components are created.

The Evolution and Benefits of C/Z Purlin Automatic Lines

One of the most significant advantages of C/Z purlin automatic lines is the improvement in efficiency. These machines can produce large quantities of purlins in a fraction of the time it would take using manual methods. As a result, production capacity is greatly enhanced, allowing manufacturers to meet the demands of the fast-paced construction industry. The automatic line can typically produce a wide range of sizes and profiles, offering flexibility to accommodate various project requirements.

Additionally, the consistency and quality of the products manufactured using automatic lines are superior. Automated processes reduce the likelihood of human error, leading to uniformity in the output. High-quality purlins translate to enhanced structural integrity for buildings, ensuring safety and longevity. Furthermore, the precision of automatic lines allows for tighter tolerances, meaning that the purlins will fit better during assembly, which can reduce labor costs on construction sites.

Cost-effectiveness is another compelling benefit of C/Z purlin automatic lines. Despite the initial investment required for such systems, the long-term savings can be substantial. The reduction in labor costs, coupled with the increased production rates, means that manufacturers can optimize their operational expenses. Moreover, high-quality and precisely manufactured purlins lead to fewer material wastages and lower return rates, contributing to overall cost savings.

In addition to these advantages, the use of automatic production lines aligns well with sustainability initiatives in the construction industry. By increasing production efficiency and reducing waste, manufacturers can contribute to a greener economy. As the demand for sustainable building solutions grows, automatic lines prove to be a viable option to produce high-quality purlins with minimal environmental impact.

In conclusion, C/Z purlin automatic lines represent a significant advancement in the manufacturing of essential structural components. Their ability to enhance efficiency, improve product quality, reduce costs, and support sustainability makes them an attractive option for modern construction needs. As technology continues to evolve, the adoption of automatic production systems in the steel industry is likely to grow, paving the way for safer and more efficient building practices.