The Rise of Arc Glazed Tile Roofing Machines Revolutionizing Construction

In recent years, the construction industry has witnessed a significant evolution in roofing technology. One of the standout innovations has been the introduction of arc glazed tile roofing machines. These machines not only streamline the production process of roofing tiles but also enhance the aesthetic appeal and durability of roofs.

What Are Arc Glazed Tile Roofing Machines?

Arc glazed tile roofing machines are specialized equipment designed for the manufacturing of glazed tiles, which are widely used in roofing systems. These machines utilize advanced technology to produce tiles that are both functional and visually appealing. The term arc refers to the unique shape of the tiles that mimic traditional clay tiles yet offer modern benefits.

The glazing process involved in these machines coats the tiles with a glass-like finish that provides numerous advantages, including increased water resistance, UV protection, and improved longevity. Unlike traditional roofing materials, glazed tiles do not fade over time and can withstand harsh weather conditions.

The Production Process

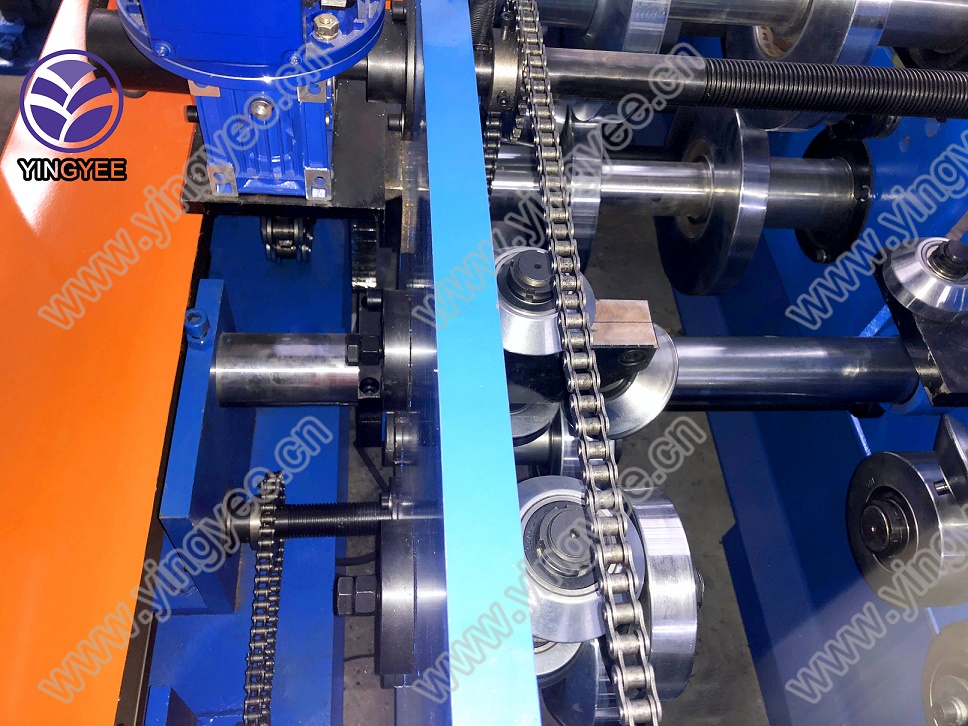

The production of arc glazed tiles begins with the selection of high-quality raw materials, typically a mix of clay and other additives. These materials are then fed into the roofing machine, where they undergo a series of processes including shaping, drying, and firing.

1. Shaping The machine molds the raw mixture into the desired tile shape. The arc design is particularly appealing as it provides a unique aesthetic that mimics traditional styles while being lightweight and easy to install.

2. Drying Once shaped, the tiles are dried to remove moisture content. This step is critical as it prepares the tiles for firing, ensuring they maintain their shape and integrity during the kiln process.

3. Firing The dried tiles are transferred to a kiln, where they are fired at high temperatures. This step not only solidifies the tiles but also plays a crucial role in achieving the desired glaze finish. The intense heat causes chemical reactions that enhance the tile’s strength and durability.

4. Glazing After firing, the tiles are coated with a liquid glaze and fired again. This glazing process forms a glass-like surface on the tile, providing it with a vibrant color and additional protection against the elements.

Advantages of Using Arc Glazed Tile Roofing Machines

1. Efficiency Traditional tile manufacturing can be labor-intensive and time-consuming. With the introduction of arc glazed tile roofing machines, production efficiency has significantly improved. These machines operate at a faster pace, reducing labor costs and minimizing production time.

2. Quality Control Automated processes ensure consistent quality across all tiles produced. This uniformity is key for construction projects, where reliability and durability are crucial.

3. Sustainability Many modern arc glazed tile roofing machines are designed with sustainability in mind. By optimizing energy use during production and minimizing waste, these machines contribute to environmentally friendly construction practices.

4. Aesthetic Versatility The arc shape and glazing options allow for a wide range of colors and finishes, enabling architects and designers to create visually stunning roofs that enhance the overall design of a building.

5. Durability Glazed tiles produced by these machines are notably more durable than their unglazed counterparts. They resist chipping, cracking, and fading, making them an excellent long-term investment for property owners.

The Future of Roofing Technology

As the demand for energy-efficient and aesthetically pleasing buildings continues to rise, the role of arc glazed tile roofing machines is likely to expand. With ongoing advancements in technology, these machines will not only improve production methods but also enhance the performance characteristics of roofing materials.

In conclusion, arc glazed tile roofing machines represent a significant advancement in roofing technology. By combining efficiency, quality, and aesthetic appeal, they offer a compelling solution for modern construction needs. As the industry continues to evolve, these machines will play a pivotal role in shaping the rooftops of tomorrow. Whether you are a builder, architect, or homeowner, understanding the benefits of these machines can help you make informed decisions about roofing options that marry functionality with style.