The Versatility of Angle Iron Roll Forming Machines

In the world of structural manufacturing, efficiency and precision are paramount. Among the various machines used for metal fabrication, angle iron roll forming machines stand out due to their unique capabilities. These machines are designed to produce angle iron—a structural component essential in a variety of construction and manufacturing applications.

Angle iron, characterized by its L shape, is widely utilized due to its excellent load-bearing properties and versatility. It is commonly used in building frames, brackets, and supports across multiple industries, including construction, automotive, and furniture manufacturing. Given its importance, the demand for angle iron is consistent, necessitating efficient production methods.

What is Angle Iron Roll Forming?

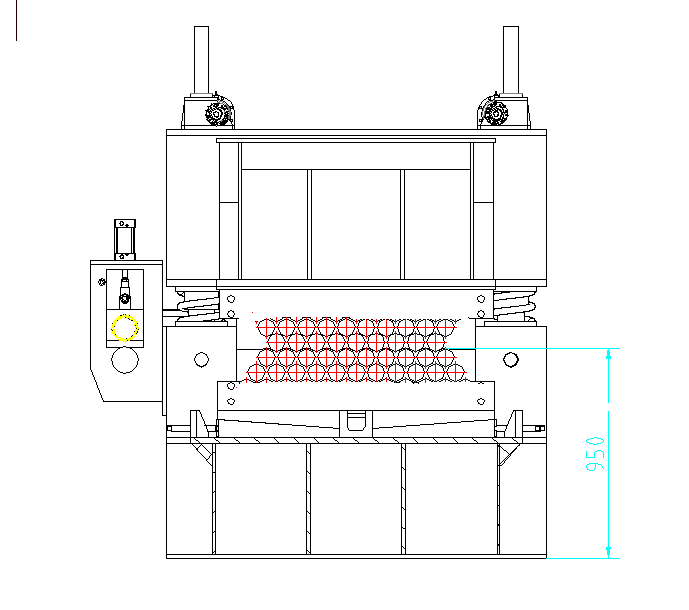

Angle iron roll forming is a continuous process that converts flat steel sheets or strips into angle iron profiles. This is achieved through a series of specially designed rollers that gradually shape the metal as it passes through the machine. The process is highly efficient, allowing for high-volume production while maintaining dimensional accuracy.

The roll forming process begins with feeding a flat strip of metal into the machine. As the metal passes through multiple sets of rollers, it is progressively shaped into the desired angle profile. This method not only ensures consistent quality but also reduces material waste—an essential factor in today's cost-conscious manufacturing environment.

Advantages of Angle Iron Roll Forming Machines

1. Efficiency One of the primary benefits of using roll forming machines is their ability to produce high volumes of angle iron quickly. This efficiency is vital for manufacturers looking to meet market demands without sacrificing quality.

2. Precision Roll forming allows for tight tolerances and consistent shapes, ensuring that every piece of angle iron meets the required specifications. This precision is critical in applications where structural integrity is paramount.

3. Flexibility Modern angle iron roll forming machines are often equipped with advanced controls and programmable features, allowing manufacturers to produce varying sizes and profiles without significant downtime. This flexibility is beneficial in a market where customization is increasingly demanded.

4. Minimal Waste The continuous nature of the roll forming process results in minimal scrap material. Better material utilization not only lowers costs but also aligns with sustainable manufacturing practices.

5. Durability Machines designed for roll forming are built to withstand continuous operation, often resulting in lower maintenance and longer lifespans compared to more traditional methods like bending or cutting.

Applications of Angle Iron

The applications of angle iron are extensive. In construction, it is used in the framework of buildings and structures, providing essential support and stability. In the manufacturing sector, angle iron serves as brackets, frames, and braces. Additionally, angle iron is utilized in the automotive industry for parts that require strength without excessive weight.

Future Trends

As technology advances, angle iron roll forming machines are becoming more sophisticated. Innovations such as automation and smart manufacturing are making these machines even more efficient. Additionally, the rise of Industry 4.0 is paving the way for real-time data monitoring and process optimization, further enhancing productivity.

In conclusion, angle iron roll forming machines play a vital role in modern manufacturing. Their efficiency, precision, and flexibility make them indispensable in producing one of the most fundamental structural components in various industries. As demand for angle iron continues to grow, investing in advanced roll forming technology will undoubtedly be a key factor in maintaining competitiveness in the marketplace.