Advancements in Wall Angle Making Machines for Drywall Applications

In the ever-evolving construction industry, efficiency and precision are paramount. As projects grow in complexity, so does the need for advanced machinery that can meet specific demands. One such innovation is the wall angle making machine, specifically designed for drywall applications. This equipment, particularly in the context of channel and stud production, plays an essential role in shaping the framework of modern buildings.

Understanding the Importance of Drywall Framework

Drywall, also known as gypsum board, has become a standard in the construction of interior walls and ceilings due to its versatility, ease of installation, and fire-resistant properties. Integral to drywall systems are the channels and studs that form the underlying structure. The studs are vertical components that support the weight of the drywall, while channels run horizontally to connect these studs, ensuring a solid framework. The accuracy in creating these angles and lengths is crucial, as it directly impacts the wall's integrity and the overall aesthetics of the space.

The Role of Wall Angle Making Machines

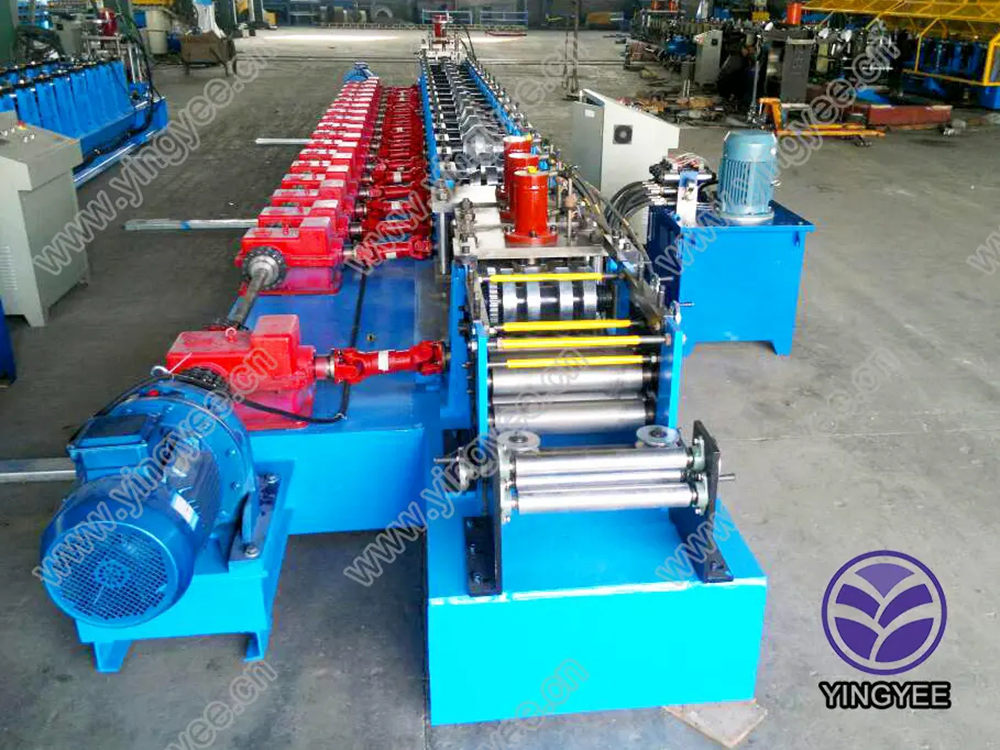

Wall angle making machines are specialized tools designed to produce the requisite channel and stud components for drywall construction. These machines can create precise angles that are vital for the drywall to fit seamlessly into place. The automation and high precision of these machines help to reduce labor costs, minimize waste, and accelerate the construction process.

These machines operate using advanced technology that allows for a high degree of customization. They can be adjusted to create different widths and angles based on the specific requirements of a project. This flexibility is particularly advantageous in a market that increasingly demands unique design elements.

Features and Advantages

Modern wall angle making machines are equipped with several features that enhance their functionality

1. Precision Cutting With CNC (Computer Numerical Control) capabilities, these machines ensure that every piece is cut to the exact specifications required, minimizing human error.

2. Speed and Efficiency Automated processes allow for rapid production, meaning more units can be manufactured in less time compared to manual methods.

3. Material Versatility Many machines are designed to work with various materials beyond just gypsum board, including metal studs and channels that cater to different construction needs.

4. User-Friendly Interface Advanced machines often feature intuitive controls that allow operators to easily program the desired specifications, further streamlining the production process.

5. Reduced Waste By ensuring precise cuts and measurements, these machines significantly reduce material wastage, contributing to a more sustainable construction approach.

Industry Trends and Future Directions

As the construction industry continues to pivot towards automation, the demand for wall angle making machines is anticipated to rise. Innovations in artificial intelligence and machine learning may further enhance the capabilities of these machines, allowing for predictive maintenance and smarter production processes. Moreover, as energy efficiency and sustainability become increasingly critical, future machines may incorporate green technologies to reduce their environmental impact.

Conclusion

The wall angle making machine is a vital component in the construction of drywall systems. Offering unparalleled precision, efficiency, and adaptability, these machines are transforming the way construction projects are approached. As advancements continue, the construction industry stands to benefit from even more innovative solutions, ensuring that building practices meet the demands of modern society while maintaining high standards of quality and sustainability. The future holds promising advancements that will revolutionize the way we build, and wall angle making machines are at the forefront of this evolution.