The Evolution of Wall Angle Making Machines A Game Changer in Construction

In the ever-evolving world of construction, efficiency and precision are paramount. One of the latest innovations to revolutionize this sector is the wall angle making machine, a vital piece of equipment in the production of drywall and gypsum stud frameworks. This machine offers an array of benefits that enhance the overall construction process, making it crucial for modern builders and contractors.

Understanding Wall Angles and Their Importance

Before delving into the specifics of wall angle making machines, it's important to understand the components involved. Wall angles, typically made from metal or gypsum, are essential for providing a clean and polished edge where walls meet ceilings or where different wall sections intersect. These angles ensure structural integrity, prevent damage, and contribute to the aesthetic appeal of the finished product.

Traditionally, wall angles were manufactured through labor-intensive methods that involved manual cutting and shaping. This process, while effective, was time-consuming and often resulted in inconsistencies in size and shape. In contrast, wall angle making machines automate this process, ensuring uniformity and precision that is hard to achieve with manual methods.

The Mechanism Behind Wall Angle Making Machines

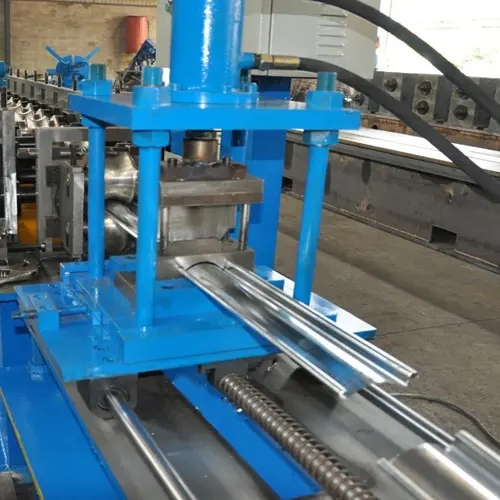

Wall angle making machines utilize advanced technology to streamline the production of wall angles. Equipped with various components like automatic feeders, cutting blades, and bending tools, these machines can produce angles of various sizes and configurations quickly and efficiently.

The process typically begins with feeding raw material, such as metal or gypsum, into the machine. The material is then cut to the required length and formed into the desired angle through bending and shaping processes. The automation involved in these machines not only speeds up production but also significantly reduces the likelihood of errors that can occur during manual manufacturing.

Advantages of Using Wall Angle Making Machines

1. Efficiency One of the most significant advantages of wall angle making machines is their ability to produce large quantities of wall angles in a fraction of the time it would take using traditional methods. This efficiency can dramatically reduce project timelines, allowing builders to meet deadlines and improve customer satisfaction.

2. Precision Automated machines provide high levels of precision that are essential in construction. Consistent dimensions and shapes not only improve the overall quality of the construction but also ensure that wall angles fit perfectly, reducing the need for adjustments and rework.

3. Cost-Effectiveness While the initial investment in a wall angle making machine may be substantial, the long-term savings are undeniable. Reduced labor costs, minimized material waste, and faster production times all contribute to a more favorable bottom line for construction companies.

4. Versatility Modern wall angle making machines can be programmed to create various types of angles, enabling builders to cater to different design requirements. Whether it's a standard angle or a custom shape needed for a unique project, these machines can adapt to the task.

5. Sustainability As the construction industry moves towards more sustainable practices, the efficiency provided by these machines also translates into less waste and a reduced carbon footprint. The precise cutting and shaping capabilities mean that less material is discarded during production.

Conclusion

The advent of wall angle making machines marks a significant advancement in the construction industry, transforming how wall angles are produced. With their unmatched efficiency, precision, cost-effectiveness, versatility, and sustainability, these machines have become indispensable for modern construction projects. As the industry continues to embrace technology, we can expect further innovations that will enhance productivity and quality in the construction sector. For builders looking to stay ahead of the curve, investing in a wall angle making machine is not just a choice; it is a smart strategy for future success.