The Evolution of Wall Angle Making Machines in Drywall Production

In the contemporary construction landscape, drywall has become a fundamental component in building structures, thanks to its efficiency, ease of installation, and versatility. Among the crucial tools that facilitate the production and installation of drywall are wall angle making machines. These machines play a pivotal role in ensuring precise and high-quality wall angles, essential for fitting drywall panels seamlessly.

The Importance of Wall Angles

Wall angles are critical components in the drywall installation process. They are designed to provide a solid framework that helps secure the panels in place while also ensuring that the joints between different drywall sheets are smooth and visually appealing. Improperly crafted wall angles can lead to weak structures, unsightly seams, and an overall compromised aesthetic. Therefore, the role of machinery in producing these angles cannot be overstated.

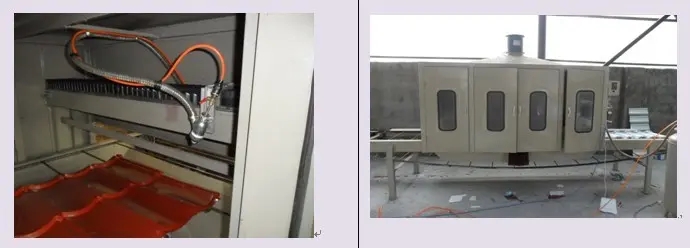

The Mechanism Behind Angle Making Machines

Wall angle making machines utilize advanced technology to produce accurate and consistent angles. The machines operate by feeding coils of gypsum or drywall material, which are then transformed into specific angles through a series of cutting, bending, and forming processes. These machines can typically produce various sizes and shapes of angles, catering to diverse construction requirements.

One of the key advantages of modern wall angle making machines is their efficiency. Automated systems reduce labor costs and time spent on production. With programmable features, users can easily adjust dimensions and settings to meet specific project needs, thereby minimizing material waste and enhancing operational efficiency.

Innovations in Technology

As technology advances, so does the machinery used in drywall production. Recent innovations have seen the integration of digital controls and sensors in wall angle making machines. These technologies improve precision and consistency while allowing for real-time monitoring of the production process. Such advancements lead to higher-quality output and reduced errors, aligning with the growing demand for premium construction materials.

Additionally, the trend toward sustainability in construction has also influenced the design of wall angle making machines. Manufacturers are increasingly focusing on creating machines that optimize resource use, allowing for the recycling of materials and ensuring that waste is kept to a minimum. This shift not only benefits the environment but also aligns with the cost-cutting measures that many construction companies are seeking.

Conclusion

The role of wall angle making machines in the drywall production industry is indispensable. As construction projects continue to evolve, the demand for efficient, precise, and sustainable production methods will only increase. By leveraging modern technology, manufacturers of wall angle making machines are well-positioned to meet these demands and contribute to the future of construction. In an industry where quality directly impacts the longevity and aesthetic appeal of buildings, investing in high-quality wall angle making machines is a step towards ensuring successful project outcomes.