The Aluminum Strut Channel Roll Forming Machine A Key Player in Modern Manufacturing

In recent years, the demand for customized aluminum components has surged, driven by various industries' needs for lightweight yet durable materials. Among the many tools and technologies enabling this, the aluminum strut channel roll forming machine has emerged as a significant player. This advanced machinery offers a reliable and efficient solution for producing strut channels, which are essential for structural systems in construction and industrial applications.

Understanding the Roll Forming Process

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled, is passed through successive pairs of shaped rollers. The rollers progressively form the strip into the desired cross-section profile, in this case, aluminum strut channels. This process provides numerous advantages, including high production rates, uniform quality, and the ability to create complex shapes with precision.

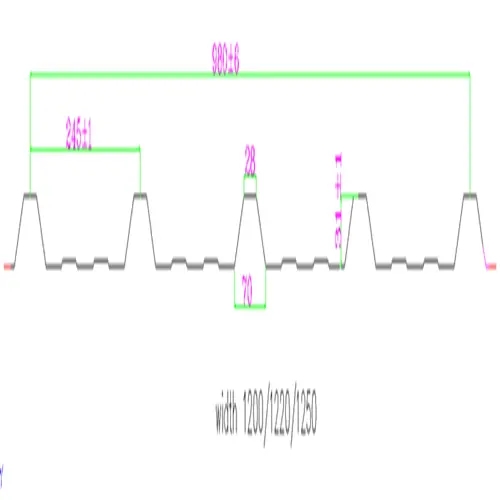

The aluminum strut channel itself is a versatile structural element characterized by its C-shaped profile. It is predominantly used in mounting applications for solar panels, HVAC systems, electrical conduits, and various other installation scenarios. The introduction of roll forming technology has made it easier for manufacturers to produce these channels in varying lengths, widths, and thicknesses while maintaining cost-effectiveness.

Significance of Aluminum in Construction

Aluminum is favored in the manufacturing of strut channels for several reasons. Firstly, it is lightweight, which reduces transportation costs and makes installation simpler. Secondly, aluminum offers excellent resistance to corrosion, ensuring that the structural components maintain their integrity over time, even in challenging environments. Thirdly, aluminum is fully recyclable, thereby appealing to environmentally conscious consumers and businesses looking to reduce their carbon footprint.

Features of the Aluminum Strut Channel Roll Forming Machine

Modern aluminum strut channel roll forming machines come equipped with state-of-the-art technology, enhancing efficiency and effectiveness. Key features include

1. High-Speed Production These machines can produce large quantities of strut channels in a fraction of the time compared to traditional manufacturing methods. 2. Adjustable Settings Many roll forming machines allow for easy adjustments to accommodate various channel sizes and designs without extensive downtime. 3. Integrated Cutting Systems Advanced models often include automatic cutting systems, ensuring that each strut channel is cut to precise lengths as it exits the forming line.

4. User-Friendly Controls Modern machines are typically outfitted with intuitive software and touch-screen interfaces, allowing operators to manage production processes efficiently.

5. Durability and Low Maintenance Built from high-quality materials, these machines are designed to withstand the rigors of high-volume production, requiring minimal maintenance to keep them running smoothly.

Conclusion

As industries continue to evolve, the demand for customized, high-quality aluminum components will only increase. The aluminum strut channel roll forming machine stands at the forefront of this evolution, offering an effective solution to meet this rising demand. With its ability to produce lightweight, durable, and environmentally friendly products, the roll forming machine serves not only the manufacturing sector but also contributes positively to the overall sustainability of modern construction practices. As technology progresses, the capabilities and efficiencies of these machines will only improve, further solidifying their role as essential tools in the industrial landscape.