The Aluminum Roofing Sheet Making Machine A Revolution in Construction

In the ever-evolving construction industry, the demand for durable and efficient building materials has led to significant innovations. One of the key advancements is the aluminum roofing sheet making machine, a pivotal tool designed to streamline the production of high-quality aluminum roofing sheets. This machine not only enhances efficiency but also caters to the growing need for sustainable and lightweight construction materials.

Aluminum roofing sheets have gained popularity due to their numerous advantages. They are lightweight, corrosion-resistant, and provide excellent insulation, making them an ideal choice for various types of buildings. With the rise in construction projects everywhere, the demand for these roofing sheets has skyrocketed, leading to the need for efficient production methods.

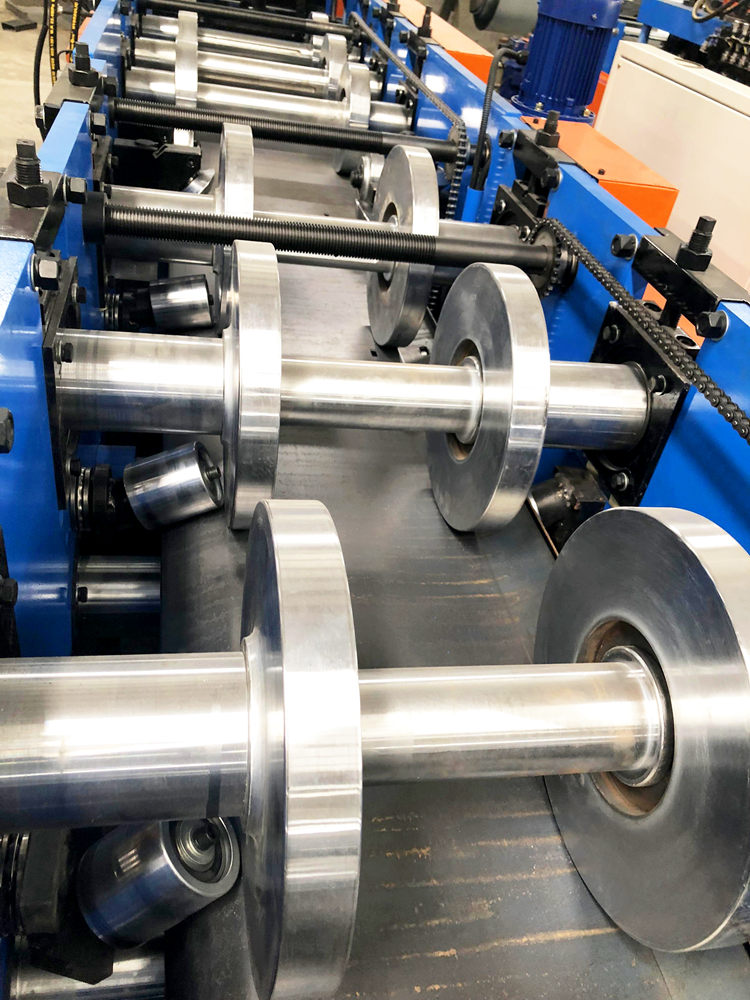

The aluminum roofing sheet making machine automates the entire process, from raw material handling to final product formation. This equipment typically consists of several components, including a decoiler, a roll forming machine, and a cutting tool. The decoiler unwinds the aluminum coils, feeding them into the roll forming machine, which shapes the material into desired profiles. Finally, the cutting tool ensures that the sheets are cut to specified lengths, ready for installation.

One of the key benefits of using an aluminum roofing sheet making machine is its ability to produce custom designs. Many construction projects require specific dimensions and styles to match architectural plans. With the advanced technology of modern machines, manufacturers can easily adjust settings to produce sheets that meet these unique specifications. This flexibility not only enhances customer satisfaction but also contributes to the overall aesthetic of the building.

Moreover, the machine's efficiency significantly reduces labor costs and production time. Traditional methods of roofing sheet fabrication often involve labor-intensive processes, which can be both time-consuming and costly. In contrast, the aluminum roofing sheet making machine can produce large quantities in a fraction of the time, allowing businesses to meet increasing demands without compromising quality.

In addition to improving production efficiency, these machines are designed with sustainability in mind. Aluminum is 100% recyclable, and utilizing an aluminum roofing sheet making machine promotes the use of eco-friendly materials. As the construction industry moves towards greener practices, this machine represents a step forward in reducing environmental impact.

In conclusion, the aluminum roofing sheet making machine is a game-changer in the construction industry, offering efficiency, customization, and sustainability. As the demand for aluminum roofing sheets continues to grow, this innovative technology will play a crucial role in shaping the future of building materials. Businesses that invest in such machinery will undoubtedly stay ahead in a competitive market, meeting the needs of both builders and consumers alike.