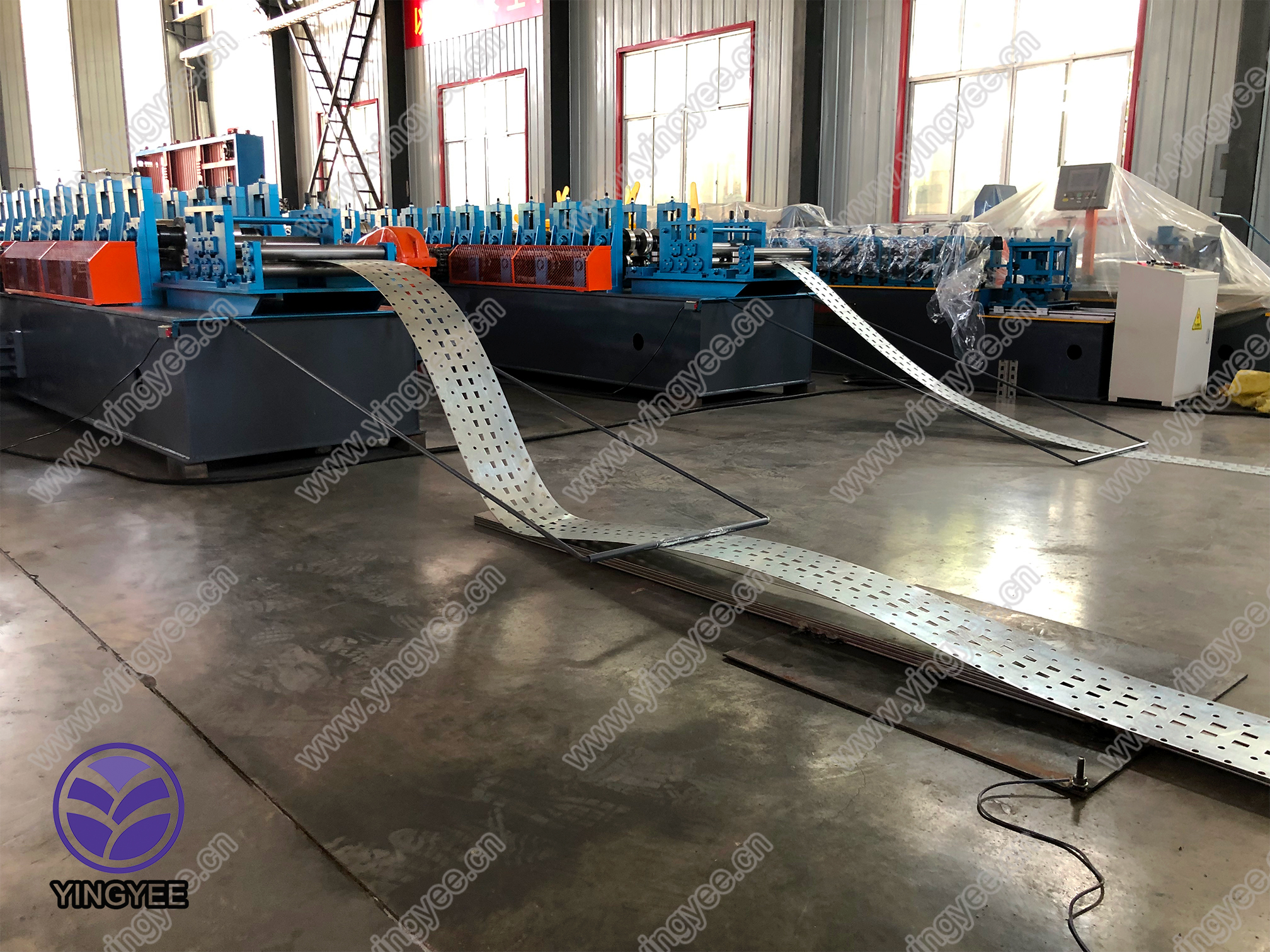

Competitive Price Steel Cable Tray Roll Forming Machine

In today's fast-paced industrial environment, the demand for efficient and cost-effective manufacturing processes is ever-increasing. One vital component in industries such as electrical installation, telecommunication, and infrastructure development is the steel cable tray. The production of these trays requires specialized machinery, including the steel cable tray roll forming machine. This article explores the significance, functionalities, and market trends associated with competitive price steel cable tray roll forming machines.

The Importance of Steel Cable Trays

Steel cable trays are integral in supporting and managing electrical cables in both commercial and residential settings. They provide a reliable way to organize cables, ensuring safety, reducing clutter, and facilitating maintenance. As industries continue to grow and expand, so does the need for high-quality cable tray systems. This increasing demand drives the need for machines that can efficiently produce cable trays while keeping operational costs low.

Features of Roll Forming Machines

The steel cable tray roll forming machine is central to producing lightweight yet sturdy cable trays. These machines operate through a series of rollers that convert flat steel sheets into pre-defined shapes. Key features include

1. Automation Most modern roll forming machines offer automation features that streamline production processes. Automation not only enhances productivity but also reduces labor costs and the likelihood of human error.

2. Customizability A competitive price steel cable tray roll forming machine can be customized to produce various sizes and shapes of cable trays. This versatility allows manufacturers to meet diverse client specifications without significant downtime for reconfiguration.

3. High Precision These machines are engineered to deliver high precision in shaping and cutting, ensuring that the final products meet strict quality standards.

4. Durability Built from robust materials, these machines are designed for longevity, capable of withstanding the rigors of continuous operation in demanding environments.

5. Efficiency With advanced technology, modern roll forming machines are designed for high-speed operation, significantly increasing the output while using less energy.

Competitive Pricing in the Market

As the demand for steel cable trays rises, so too does the number of manufacturers producing roll forming machines. This increase in competition leads to more competitive pricing options. Manufacturers are now focusing not only on the quality of their machines but also on how to offer the best value for money. Factors influencing this competitive pricing include

- Economies of Scale Manufacturers that produce in bulk can lower their costs, allowing them to offer competitive prices to buyers without compromising quality. - Technological Advancements As technology evolves, production processes become more efficient, reducing operational costs and enabling manufacturers to pass savings on to customers.

- Global Sourcing Many roll forming machines are made with parts sourced from various countries, which can lead to cost advantages. Manufacturers who can source materials at lower prices can offer more competitive pricing.

Conclusion

The steel cable tray roll forming machine plays a crucial role in the manufacturing landscape of cable management systems. With features like automation, precision, and durability, these machines are indispensable for companies seeking to capitalize on the growing demand for cable trays. As competition in the market intensifies, manufacturers are increasingly focusing on providing competitive price options, ensuring that businesses can access high-quality production equipment without straining their budgets. As industries evolve, the role of the roll forming machine will undoubtedly grow in importance, driving innovation and efficiency in cable tray manufacturing.