The Evolution and Significance of Square Downpipe Roll Forming Machines

In the construction and manufacturing industries, the efficiency and precision of production processes are paramount. Among the various types of machinery that have emerged to enhance productivity, the square downpipe roll forming machine stands out as a vital tool in the production of rainwater drainage systems. These machines streamline the manufacturing of square downpipes, which are essential components for effective water drainage in both residential and commercial buildings.

Understanding Roll Forming Technology

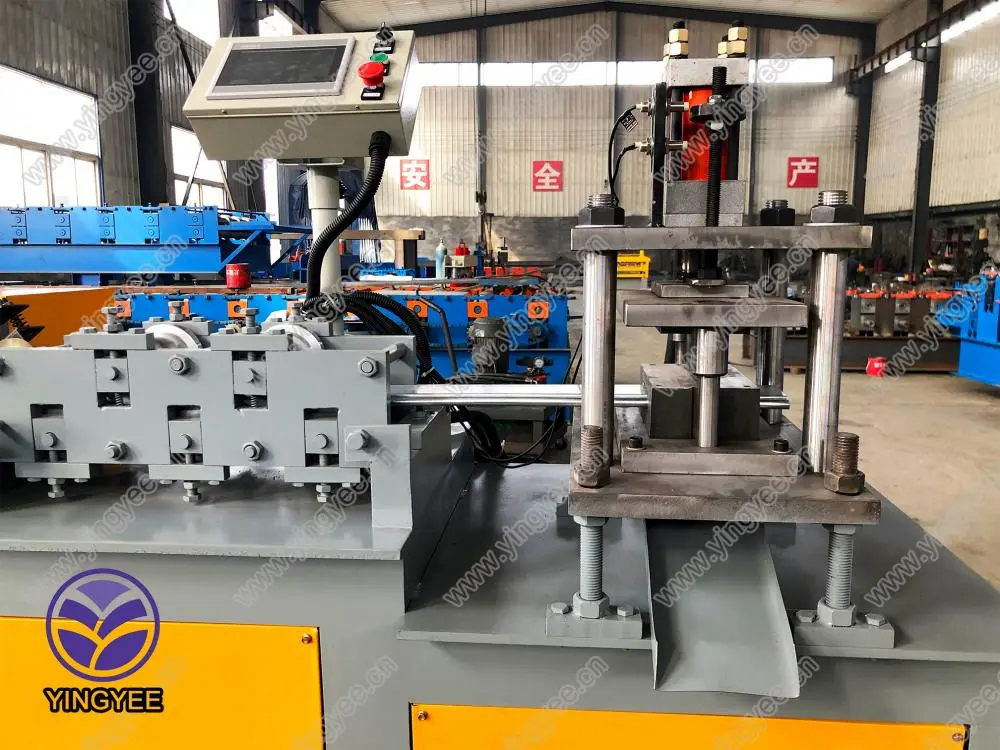

Roll forming is a manufacturing process that involves feeding a strip of metal through a series of rollers. These rollers gradually shape the metal into the desired profile without significantly changing its thickness. The process is continuous, making it highly efficient for high-volume production runs. When it comes to square downpipes, the roll forming machine specifically shapes the metal into a square or rectangular profile, which is critical for modern architectural designs.

Key Features of Square Downpipe Roll Forming Machines

Today's square downpipe roll forming machines are equipped with advanced technology to enhance their performance. Features such as programmable logic controllers (PLCs), automatic feeding systems, and precision cutting mechanisms allow for greater control and accuracy in the manufacturing process. Additionally, some modern machines can produce downpipes of various sizes and thicknesses, making them versatile tools for manufacturers catering to different market demands.

Another important feature is the ability to handle various materials, including galvanized steel, aluminum, and stainless steel. This flexibility enables manufacturers to produce downpipes that meet specific properties required for different environmental conditions, such as corrosion resistance in coastal areas or strength in heavy snowfall regions.

The Benefits of Using Roll Forming Machines

The adoption of square downpipe roll forming machines comes with a host of benefits. Firstly, they significantly reduce production time and labor costs. Traditional methods of producing downpipes often involve multiple steps, whereas roll forming simplifies this process into a single, continuous operation. Moreover, the high precision of roll forming reduces material waste, allowing manufacturers to optimize their resources and minimize costs.

Secondly, products manufactured with these machines typically exhibit superior quality and consistency. The continuous nature of the roll forming process ensures that each downpipe meets exact specifications, which is crucial for installation in drainage systems where alignment and fit are critical.

Lastly, the machines contribute to sustainability in manufacturing. By minimizing waste and optimizing material use, companies can reduce their environmental footprint. Additionally, the durable nature of the downpipes produced leads to longer product lifespans, further enhancing their sustainability.

Conclusion

As the construction industry continues to evolve, the significance of innovative machinery such as square downpipe roll forming machines cannot be overstated. They represent a perfect blend of technology and efficiency, allowing manufacturers to produce high-quality drainage solutions that meet the demands of modern architecture. By leveraging the capabilities of these machines, manufacturers not only improve their productivity but also contribute to more sustainable practices in the industry. As the market for eco-friendly and efficient building solutions grows, the roll forming machine will undoubtedly play a crucial role in shaping the future of construction.