Understanding the Study and Tracking Frame Forming Machine

In contemporary manufacturing and construction sectors, efficiency and precision are paramount. One of the notable innovations aiding these industries is the study and track frame forming machine. This sophisticated piece of equipment plays a crucial role in the production of structural frames, which are essential for a multitude of applications ranging from buildings to vehicles.

What is a Study and Track Frame Forming Machine?

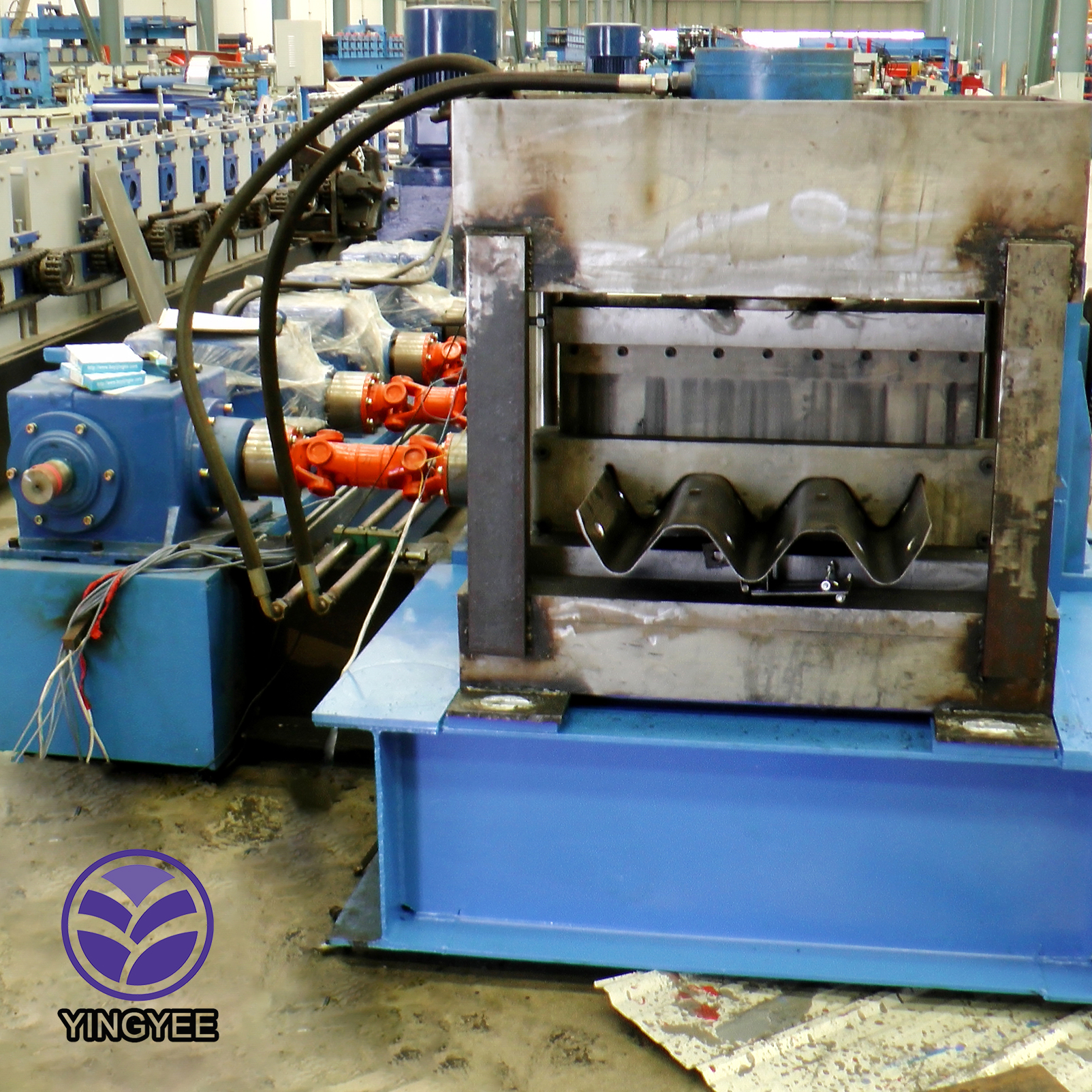

The study and track frame forming machine is designed to automatically produce frames from various materials, including steel, aluminum, and composite materials

. It utilizes advanced technology to shape and assemble frames with intricate designs while ensuring high accuracy and repeatability. This machine significantly reduces human error and operational costs, making it an invaluable asset in industrial environments.Key Features and Technologies

1. Automation One of the standout features of the frame forming machine is its automation capabilities. This includes automated feeding systems, cutting, bending, and welding processes. By minimizing manual intervention, the machine not only enhances productivity but also ensures that the frames are produced consistently to exact specifications.

2. Tracking Systems The tracking system is crucial for maintaining precision during the framing process. Advanced sensors and software enable the machine to monitor the positioning of materials in real time, making adjustments as necessary to avoid defects. This adaptive capability is particularly beneficial in high-volume production environments where errors can lead to significant financial losses.

3. Modularity Many modern frame forming machines are designed to be modular, allowing manufacturers to customize their systems based on specific requirements. This flexibility enables businesses to switch between different frame designs and materials easily, thereby catering to diverse market demands without incurring substantial costs.

4. Integration with CAD Systems The ability to integrate seamlessly with Computer-Aided Design (CAD) software is another significant advantage. Designers can create complex frame structures digitally, which the forming machine can then replicate with precision. This synergy between design and execution accelerates the transition from concept to finished product.

Applications Across Industries

The study and track frame forming machine finds applications in various industries, including

- Construction In the construction industry, these machines are vital for producing steel frames for buildings and bridges, ensuring they meet structural integrity standards. - Automotive The automotive sector utilizes frame forming machines for producing chassis and other structural components, ensuring lightweight yet durable designs that enhance fuel efficiency. - HVAC and Infrastructure Additionally, these machines are employed in the production of frames for heating, ventilation, and air conditioning (HVAC) systems, providing the structural support necessary for complex installations.

Benefits

The incorporation of study and track frame forming machines into industry practices brings numerous benefits

- Increased Efficiency Automation reduces time spent on frame production. - Cost-effectiveness By minimizing labor costs and material waste, companies can significantly enhance their profit margins. - Enhanced Quality Control The precision of these machines ensures that every frame produced meets stringent quality standards, reducing the likelihood of errors and subsequent rework. Conclusion

In summary, the study and track frame forming machine embodies the convergence of technology and innovation in the manufacturing landscape. Its automation, precision tracking, and compatibility with design software position it as a game-changer in various industries. By streamlining the frame production process, companies can not only improve their operational efficiency but also deliver superior products that meet the demanding standards of today’s market. As industries continue to evolve, the significance of such advanced machinery will undoubtedly grow, shaping the future of manufacturing and construction.