The Evolution and Significance of Steel Bar Mesh Welding Machines

In construction and industrial manufacturing, the reliability and durability of materials are of utmost importance. One of the most innovative solutions that have emerged in recent years is the steel bar mesh welding machine. This advanced technology plays a vital role in producing steel mesh, which is crucial for reinforcing concrete structures, enhancing their strength and longevity.

What is a Steel Bar Mesh Welding Machine?

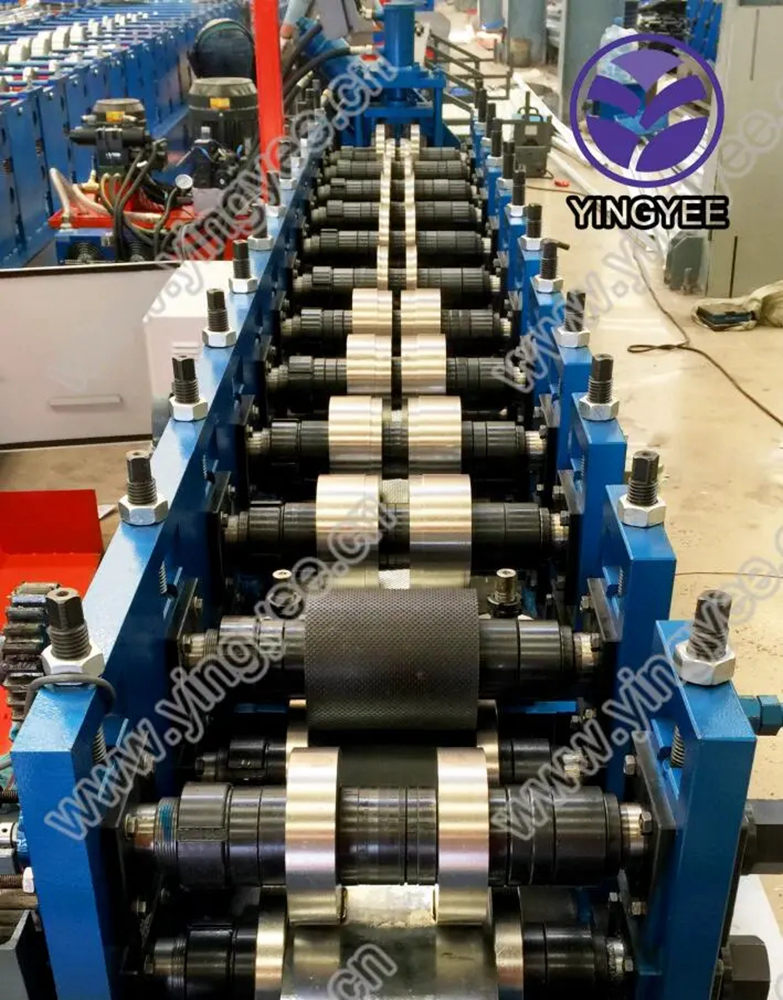

A steel bar mesh welding machine is a specialized piece of equipment designed to automatically produce welded wire mesh from steel bars. It typically features a series of vertical and horizontal wires that are intertwined and welded together at predetermined intervals. This process creates a robust mesh that can be used in various applications, from building foundations to road construction, offering a reliable solution for load-bearing structures.

The Process of Mesh Production

The operation of a steel bar mesh welding machine can be divided into several key steps. Initially, the raw steel bars are fed into the machine, which then cuts them to the required lengths. The vertical bars are positioned and secured, followed by the alignment of the horizontal bars. Using high-frequency welding technology, the machine generates heat at the contact points, fusing the bars together with precision. This automated process ensures uniform quality and minimizes human error, significantly enhancing the efficiency of mesh production.

Advantages of Steel Bar Mesh Welding Machines

1. Increased Productivity The speed and automation of steel bar mesh welding machines allow for higher output compared to traditional manual methods. This increased productivity leads to shorter project timelines and reduced labor costs, making it an economically viable option for large-scale construction projects.

2. Consistent Quality Automated welding ensures that each weld is uniform, reducing the variability that can occur with manual welding. This consistent quality is critical for infrastructure projects where safety is paramount.

3. Versatility These machines can produce various mesh sizes and configurations, accommodating different project requirements. Whether for residential construction or heavy-duty industrial applications, the steel bar mesh welding machine provides the flexibility needed in a rapidly evolving market.

4. Enhanced Durability The welded mesh produced is known for its strength and durability. By effectively distributing loads, it helps prevent cracking and deformation in concrete structures, enhancing their overall lifespan.

5. Labor Efficiency As these machines automate the welding process, they significantly reduce the need for skilled labor, addressing challenges in industries facing labor shortages.

The Impact on the Construction Industry

The integration of steel bar mesh welding machines into construction practices marks a significant advancement in building technology. This machinery not only improves efficiency but also raises safety standards within construction sites. The predictable nature of machine-produced mesh allows engineers and architects to adhere to strict regulations, ensuring that all projects meet the necessary safety criteria.

Furthermore, as global infrastructure demands continue to rise, the capability of these machines to quickly produce high-quality steel mesh helps meet these challenges head-on. In regions where building projects are burgeoning, this technology can play a pivotal role in accelerating development while maintaining high standards.

Conclusion

In conclusion, steel bar mesh welding machines represent a technological leap that enhances productivity, quality, and safety in construction practices. As the industry continues to evolve, the importance of such innovations will become more pronounced, cementing their place as crucial elements in modern manufacturing and construction processes. Embracing these advancements not only promotes efficiency but also lays the groundwork for a safer and more resilient built environment.