Solar Structure Roll Forming Machine Enhancing Renewable Energy Production

In today’s environment-conscious world, renewable energy sources have gained unprecedented importance. Among these, solar energy stands out as one of the most efficient and sustainable alternatives to fossil fuels. A key component in harnessing solar energy is the solar structure, which holds and supports solar panels in optimal positions to capture sunlight. To efficiently manufacture these structures, the solar structure roll forming machine has become an invaluable asset in the solar energy industry.

What is a Solar Structure Roll Forming Machine?

A solar structure roll forming machine is a specialized equipment designed to create metal components — typically from steel or aluminum — that form the framework for solar energy systems. These machines use a continuous process that involves feeding coiled metal sheets through a series of rollers. The rollers are strategically arranged to gradually shape the metal into desired profiles, such as rails, brackets, and frames suited for solar panel installation.

The Benefits of Roll Forming in Solar Structure Production

One of the primary advantages of using a roll forming machine is its efficiency

. The continuous production process minimizes waste, as the material is shaped rather than cut. This not only leads to cost savings but also promotes eco-friendliness, aligning with the sustainable nature of solar energy.Additionally, the precision of roll forming ensures that the structures produced meet strict industry standards for durability and strength. This is especially critical in regions facing extreme weather conditions, where solar structures must endure high winds, heavy snow loads, and even seismic events. The consistency and reliability of roll-formed components contribute to the overall performance of solar energy systems.

Automation and Customization

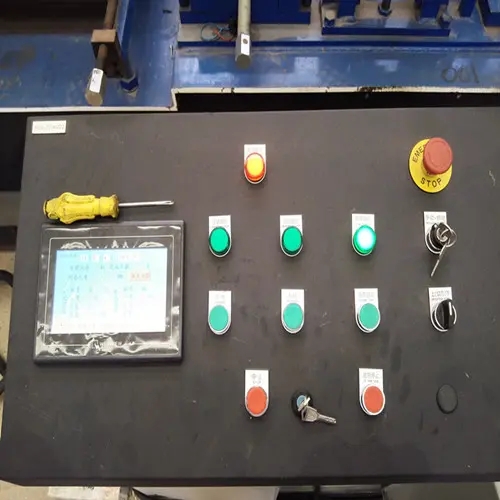

Modern solar structure roll forming machines are equipped with advanced automation features, allowing for higher levels of customization and flexibility. This means manufacturers can easily alter the specifications of the components they produce to meet the varying requirements of different solar projects. Whether it’s a residential solar installation or a large-scale solar farm, the machine can be configured to create specific profiles that maximize energy absorption while adhering to local regulations.

The automation aspect also plays a significant role in increasing production speeds. Quick changeovers reduce downtime and allow manufacturers to respond effectively to market demands, enhancing overall productivity.

Integration with the Solar Industry

The integration of roll forming technology within the solar industry is indicative of broader trends toward mechanization and innovation in renewable energy. By employing these machines, companies in the solar sector can ensure a steady supply of high-quality structures that can be rapidly deployed, supporting the growth and development of solar farms globally.

Furthermore, as the solar industry expands, so does the need for scalable solutions that can adapt to the evolving technology and installation practices. Roll forming machinery not only meets this demand but also improves the overall cost-effectiveness of solar project implementation.

Conclusion

In conclusion, the solar structure roll forming machine represents a significant advancement in the manufacturing of solar panel support structures. As the world continues to shift towards renewable energy sources, the effective production of durable, customizable, and efficient solar structures will remain critical. Not only do these machines contribute to the efficiency and sustainability of solar energy production, but they also embody the innovation necessary to meet the challenges and opportunities in the rapidly evolving energy landscape. Embracing such technology is essential for any business looking to thrive in the clean energy sector, paving the path for a greener future.