Understanding IBR Profiles and Double Layer Roofing Forming Machines

The building and construction industry has seen significant advancements in technology, leading to the development of innovative machinery designed to improve efficiency and quality. One of these innovations is the IBR (Inverted Box Rib) profiles double layer roofing forming machine. This equipment plays a crucial role in producing roofing materials that are both durable and aesthetically pleasing.

What Are IBR Profiles?

IBR profiles are a type of metal sheet used extensively in roofing applications. Their unique design features an inverted box rib pattern that provides structural strength and a visually appealing finish. This profile is popular in commercial, industrial, and residential buildings due to its excellent load-bearing capacity and resistance to environmental factors. The IBR profile not only enhances the appearance of a structure but also contributes to its longevity, making it a preferred choice in various construction projects.

The Role of Double Layer Roofing Forming Machines

Double layer roofing forming machines are advanced pieces of equipment that can produce two different profiles simultaneously. This capability greatly increases production efficiency and reduces manufacturing costs. With the ability to form IBR profiles along with another design, such as a trapezoidal or corrugated sheet, these machines cater to diverse roofing requirements and preferences.

One of the primary advantages of double layer machines is their versatility. They can be easily adjusted to switch between different profiles, allowing manufacturers to meet varying customer demands without needing additional machinery. This adaptability proves beneficial in today's dynamic construction market, where demand can fluctuate quickly.

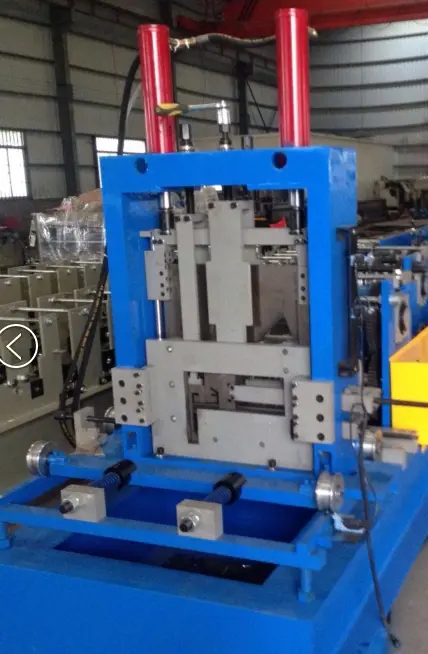

Key Features of IBR Profiles Double Layer Roofing Forming Machines

Modern IBR profiles double layer roofing forming machines come equipped with numerous advanced features that enhance their functionality and user experience

1. Robust Construction These machines are designed to withstand heavy workloads and challenging operational environments. Made from high-quality materials, they ensure consistent performance over extended periods.

2. High Production Speed With advanced technology, these machines can produce roofing sheets at remarkable speeds, significantly increasing production capacity.

3. User-Friendly Interface Many machines feature intuitive control systems that allow operators to easily switch between profiles and adjust settings, minimizing training time and operational errors.

4. Wastage Reduction Advanced engineering ensures that raw materials are used efficiently, reducing waste and contributing to more sustainable manufacturing practices.

5. Customizable Options Clients can request machines designed to meet their specific requirements, including automatic stackers, shearers, or additional roll stations, providing a tailored production solution.

Applications of IBR Profiles

The application of IBR profiles is widespread. They are utilized in the construction of warehouses, factories, shops, and even residential buildings. Their ability to effectively shed water and resist rust makes them ideal for areas with heavy rainfall or humidity. Additionally, their aesthetically pleasing finish contributes positively to the overall design of structures.

Conclusion

In conclusion, the IBR profiles double layer roofing forming machine symbolizes the cutting-edge advancements in the construction industry. With its ability to produce high-quality, durable roofing materials efficiently, it serves as a vital tool for manufacturers. The versatility and innovative features of these machines not only improve productivity but also enable businesses to meet the evolving needs of the construction market. As technology continues to evolve, we can expect further enhancements in machinery, leading to even greater efficiencies and capabilities in roofing materials production.