The Importance of Highway Guardrail Machines in Road Safety

Highway safety is an essential aspect of modern infrastructure, ensuring not only the protection of vehicles but also the safety of passengers and pedestrians. Among the various safety features incorporated into roadways, guardrails play a crucial role in preventing accidents and protecting lives. To manufacture and install these vital structures effectively, highway guardrail machines have emerged as indispensable tools in the construction industry.

Understanding Highway Guardrails

Guardrails are protective barriers designed to prevent vehicles from leaving the roadway in critical areas such as curves, slopes, and bridges. They serve multiple functions, including redirecting vehicles back onto the road, protecting pedestrians, and shielding hazardous areas, such as cliffs or bodies of water. The design and material used for guardrails can vary depending on their intended application, but the overall goal remains constant to enhance road safety.

The Role of Highway Guardrail Machines

Highway guardrail machines are specialized equipment designed to manufacture, install, and maintain guardrails efficiently. These machines significantly streamline the process of producing guardrails by automating various tasks, reducing manual labor, and minimizing human error. By using advanced technology, these machines can create guardrails with precision and consistency, ensuring that they meet safety standards and regulations.

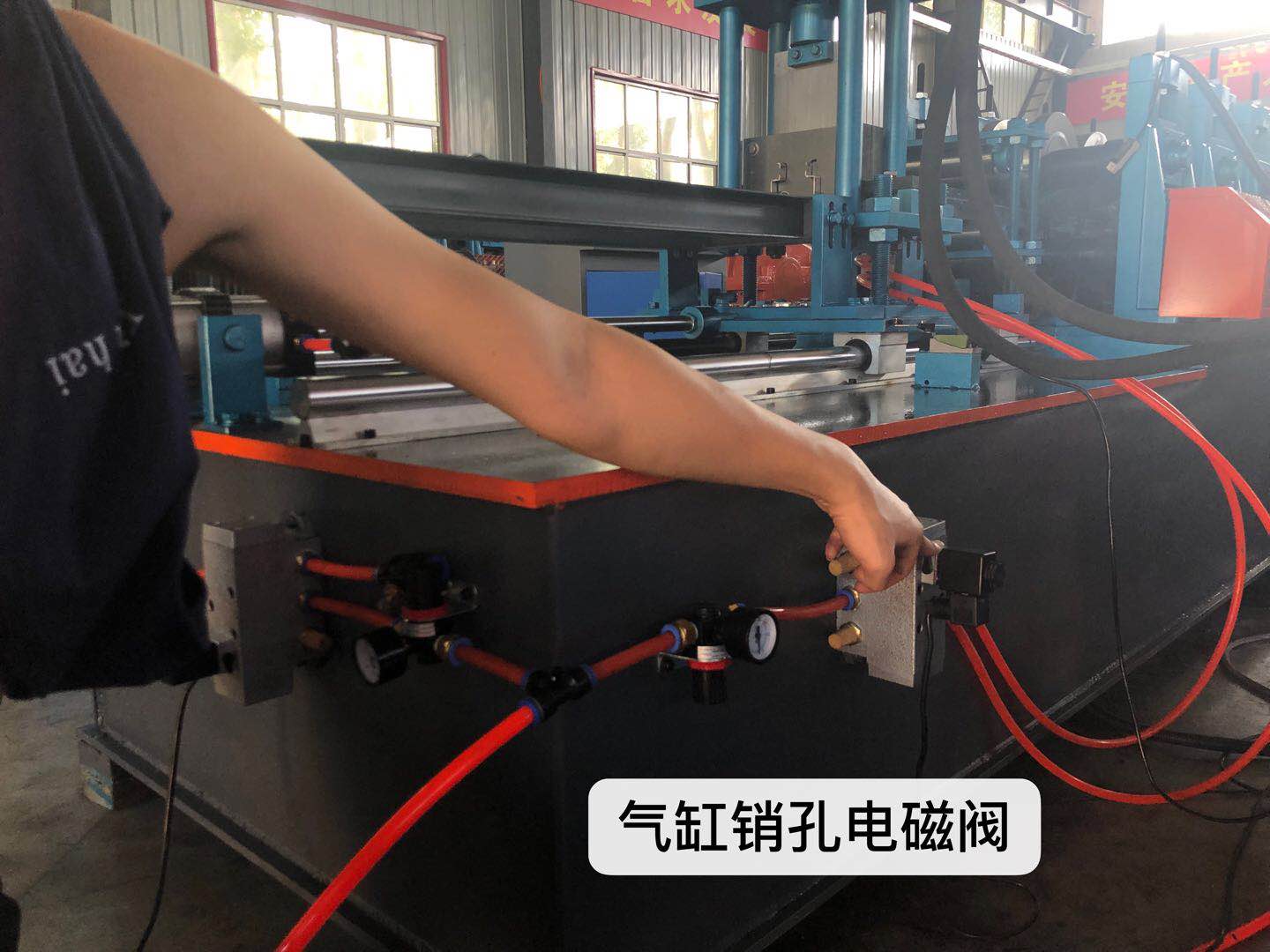

One primary function of highway guardrail machines is the fabrication of guardrail components. The machines are capable of cutting, bending, and shaping steel or other materials into required specifications. This automated fabrication not only accelerates production times but also enhances the overall quality of the guardrails, making them more durable and effective.

Benefits of Utilizing Guardrail Machines

1. Increased Efficiency Highway guardrail machines significantly reduce production and installation time. This efficiency translates into lower labor costs and quicker project completion times, allowing for more timely upgrades and maintenance of road systems.

2. Improved Safety By producing guardrails with precision, these machines contribute to enhancing road safety. Well-manufactured guardrails are more reliable in preventing accidents and protecting drivers.

3. Cost-Effectiveness Automating production through these machines reduces the need for extensive manual labor. This shift not only cuts costs but also minimizes waste and material usage, leading to more economical project budgets.

4. Consistency in Quality Highway guardrail machines ensure that every component produced meets consistent quality standards. This uniformity is essential in maintaining the integrity of safety features on the roadway.

Future Prospects

With advancements in technology, the future of highway guardrail machines looks promising. Innovations such as robotics and artificial intelligence could further enhance their capabilities. The introduction of smart technologies can allow these machines to monitor guardrail integrity over time, providing data that can predict maintenance needs and prevent potential hazards.

Moreover, as the focus on sustainable practices grows, the industry may see the development of machines that utilize eco-friendly materials and processes. Enhanced materials that offer better durability and environmental benefits can lead to even safer and more sustainable road infrastructure.

Conclusion

Highway guardrail machines play a vital role in the construction and maintenance of safe roadways. Their ability to produce high-quality guardrails efficiently and cost-effectively contributes significantly to reducing road accidents and enhancing overall safety. As technology continues to evolve, these machines will undoubtedly play an even more vital role in shaping the future of road safety, ensuring that highways remain safe for all users.