The Evolution and Importance of Color Steel Roofing Sheet Making Machines

In the realm of construction and architecture, the roofing materials used play a crucial role not only in aesthetics but also in durability and functionality. Among the various roofing options available today, color steel roofing sheets have emerged as a popular choice due to their remarkable advantages. To meet the rising demand for these materials, highly efficient color steel roofing sheet making machines have been developed, marking a significant advancement in the manufacturing industry.

Color steel roofing sheets are steel substrates coated with layers of paint and protective materials, giving them a vibrant appearance while enhancing their resistance to corrosion, rust, and environmental wear and tear. They are widely used in residential, commercial, and industrial buildings, and their versatility allows for a range of styles and colors that can suit any architectural design. As the construction industry seeks to combine aesthetics with functionality, the use of color steel roofing sheets has skyrocketed, leading to increased production needs.

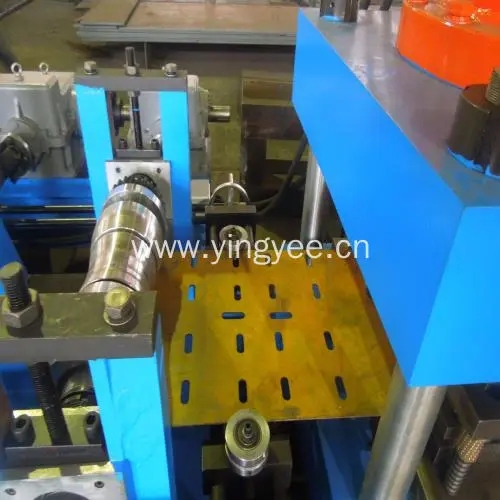

This is where color steel roofing sheet making machines come into play. These specialized machines are designed to produce roofing sheets with precision and efficiency. They typically employ advanced technologies, such as automated roll forming and cutting processes, which significantly reduce manual labor and lead times. By utilizing high-grade raw materials, these machines ensure that the final product not only meets aesthetic standards but also complies with safety and durability regulations.

The production process begins with the feeding of steel coils into the machine, where it is uncoiling and fed into a roll forming machine. This machine progressively shapes the steel into the desired profile through a series of rollers. During the shaping process, the color coating is applied, providing the sheets with both the protective layer and the vibrant finish that makes them highly desirable for building applications. Subsequent processes involve cutting the sheets to the required lengths, ensuring consistency and accuracy in the output.

One of the key advantages of using modern color steel roofing sheet making machines is the ability to customize production on-demand. This flexibility allows manufacturers to respond quickly to market trends and customer needs, producing sheets in various colors, thicknesses, and profiles without significant downtime. Moreover, the enhanced automation in these machines minimizes human error, leading to less waste and improved production efficiency.

In addition to their production capabilities, color steel roofing sheet making machines also have an environmental impact worth noting. The advancement in technology has allowed for processes that reduce energy consumption and waste during manufacturing. Many machines are now equipped with recycling systems that utilize off-cuts and scrap materials, further promoting sustainability in the production cycle.

As the demand for eco-friendly and sustainable building materials grows, the role of color steel roofing sheets and their manufacturing machines becomes increasingly critical. They not only cater to the aesthetic requirements of modern architecture but also align with the global movement toward greener building practices.

In conclusion, color steel roofing sheet making machines are pivotal in the construction industry, driving the production of popular roofing materials that merge durability with design. As technology advances and the market continues to evolve, these machines will undoubtedly play a fundamental role in shaping the future of roofing solutions, ensuring that builders and homeowners can enjoy both beauty and functionality in their structures. The investment in such machinery represents not just a commitment to quality but also an awareness of sustainable practices that benefit the environment and the economy alike.