The H2 W4 Spacer Cold Bending Machine Revolutionizing Construction

In the ever-evolving world of construction and engineering, the tools and machines we utilize play a pivotal role in determining the efficiency and quality of our work. Among the latest advancements in this domain is the H2 W4 Spacer Cold Bending Machine, a cutting-edge piece of equipment that enhances productivity and precision in bending operations for construction materials. This article aims to explore the significance, functionality, and advantages of this innovative machine.

Understanding the H2 W4 Spacer Cold Bending Machine

The H2 W4 Spacer Cold Bending Machine is designed specifically for bending various types of metals and materials used in construction, particularly for creating spacers that ensure structural integrity in concrete constructions. This machine employs a cold bending process, meaning that it bends materials at room temperature without the need for heat application. This method retains the material's properties, preventing any alterations that might compromise performance.

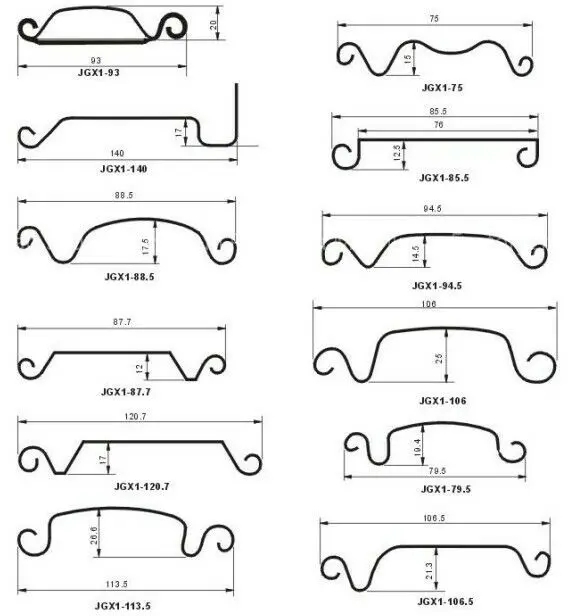

One of the defining features of the H2 W4 is its ability to handle a diverse range of materials, including rebar, wire, and other metals. The machine is engineered for versatility, making it suitable for various bending requirements in construction projects, from residential buildings to large-scale infrastructure.

Key Functions and Mechanisms

At the heart of the H2 W4 Spacer Cold Bending Machine is its advanced hydraulic system, which provides the necessary force for bending materials accurately and efficiently. The machine comes equipped with user-friendly controls that allow operators to set precise bending angles and lengths, ensuring that every component meets the project's specifications.

Moreover, the machine's design incorporates safety features, such as emergency stop buttons and safety guards, to protect operators during the bending process. This focus on safety not only safeguards the workforce but also minimizes the risk of damage to the materials being processed.

Advantages of the H2 W4 Spacer Cold Bending Machine

1. Increased Efficiency The H2 W4 significantly reduces the time required for bending operations. This efficiency translates to faster project completion times, allowing construction teams to adhere to tight schedules without compromising quality.

2. Cost-Effectiveness By minimizing material waste and reducing labor hours, the machine provides a cost-effective solution for contractors. The initial investment is quickly offset by the savings achieved in both time and material.

3. Improved Accuracy The precision control offered by the H2 W4 ensures that every bend is executed with exactitude, which is vital for the structural integrity of construction projects. This accuracy leads to fewer errors and reworks, enhancing the overall quality of the construction.

4. Flexibility in Design The machine's capacity to produce various shapes and sizes of spacers means that designers and engineers have greater freedom to innovate. This versatility is crucial in modern construction, where unique design builds often push the boundaries of traditional methods.

5. Durability and Reliability Built with high-quality materials and components, the H2 W4 is engineered for longevity. This durability makes it a reliable fixture on construction sites, capable of withstanding the rigors of daily use.

Conclusion

The H2 W4 Spacer Cold Bending Machine exemplifies the advancements in construction technology that continue to shape the industry. Its combination of efficiency, precision, and versatility makes it an invaluable asset for contractors looking to optimize their operations. As the construction sector continues to embrace technological innovations, machines like the H2 W4 are setting new standards for quality and performance, paving the way for a more efficient future in construction.