The Big Span Roll Forming Machine A Revolution in Metal Fabrication

In recent years, the construction and manufacturing industries have witnessed significant advancements in machinery and automation technology. One of the standout innovations in metal fabrication is the Big Span Roll Forming Machine. This robust piece of equipment has transformed the way steel and other metals are processed, offering remarkable efficiency and precision in producing large spans of structural components.

What is a Big Span Roll Forming Machine?

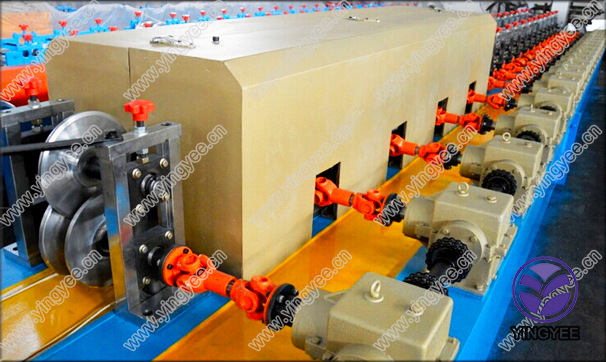

At its core, a Big Span Roll Forming Machine is designed to continuously shape metal sheets into various profiles, such as beams, columns, and panels, through a series of rollers. This technology enables manufacturers to create long, continuous lengths of materials with consistent cross-sectional shapes, which are essential for large-scale construction projects like warehouses, distribution centers, and commercial buildings.

Advantages of Big Span Roll Forming Machines

1. Efficiency and Speed One of the primary benefits of utilizing a Big Span Roll Forming Machine is its high production speed. The machine can form large quantities of metal profiles in a fraction of the time it would take traditional methods, significantly boosting productivity. This efficiency is crucial for meeting tight deadlines in construction projects.

2. Material Savings With a precise roll forming process, waste is minimized. The machine can produce components with exact specifications, reducing excess material that often results from more conventional manufacturing techniques. This not only cuts costs but also promotes sustainable practices by minimizing scrap metal.

3. Versatility Big Span Roll Forming Machines are capable of producing an array of different shapes and sizes, allowing them to cater to diverse project requirements. Whether a project needs eaves, gutters, or support beams, these machines can be adjusted to create customized profiles without the need for extensive retooling.

4. Strong Structural Integrity The roll forming process imparts considerable strength to the finished products. The cold-formed steel generated by these machines is known for its durability and resistance to deformation, which is crucial for structural applications in buildings and infrastructure.

5. Automated Production Many modern roll forming machines are equipped with advanced automation capabilities, including computerized controls and integration with design software. This level of automation not only streamlines the production process but also enhances precision, leading to higher-quality outputs.

Applications in Modern Construction

The applications of Big Span Roll Forming Machines in construction are vast. They are particularly well-suited for projects that require large, open spaces without intermediate columns, such as

- Industrial Warehouses The ability to create long spans without support allows for efficient use of space and flexibility in operations. - Commercial Buildings Retail spaces benefit from the aesthetic appeal of large, unobstructed interiors. - Agricultural Structures Equipment sheds and storage facilities utilize the strength and light weight of roll-formed steel for cost-effective building solutions.

Conclusion

The Big Span Roll Forming Machine represents a leap forward in the field of metal fabrication, combining speed, efficiency, and precision. As industries continue to embrace innovative machinery, the role of these machines in the construction sector is poised to grow even further. By enabling the creation of robust structures with minimal waste and time, Big Span Roll Forming Machines are not only revolutionizing the way we build but also paving the way for a more sustainable future in construction. As the demand for durable and versatile materials increases, these machines will undoubtedly play an essential role in shaping the skylines of tomorrow.