The Acoustical Barrier Cold Bending Machine An Essential Tool for Modern Construction

In the realm of construction and architecture, noise pollution has emerged as a significant concern

. It not only impacts the quality of life but also affects health and productivity. To address this, acoustical barriers have become indispensable in urban environments, and the cold bending machine plays a crucial role in their production.The acoustical barrier is designed to mitigate sound transmission between spaces, especially in noisy environments like highways, industrial areas, and busy urban locales. These barriers are often made of materials such as concrete, metal, or specialized composites that effectively absorb or deflect sound waves. However, creating these barriers requires precise engineering and craftsmanship, which is where the cold bending machine comes into play.

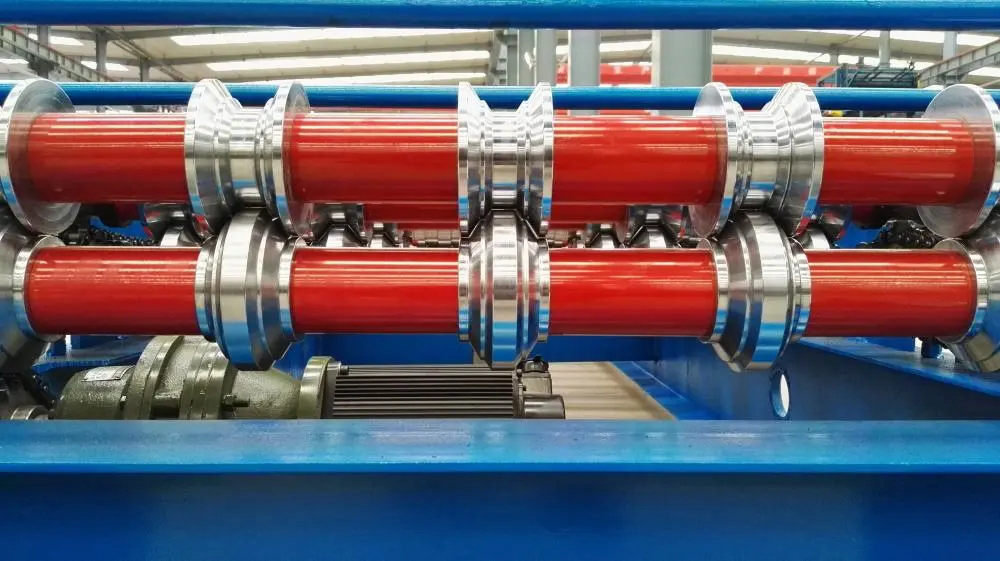

A cold bending machine is specifically engineered to bend materials without the application of heat. This process is essential for maintaining the integrity and properties of materials typically utilized in the manufacturing of acoustical barriers. The machine employs hydraulic or mechanical methods to bend materials into desired shapes while preventing any structural deformation that could compromise their soundproofing capabilities.

One of the main advantages of using a cold bending machine is its efficiency. It allows for rapid production of customized barrier panels that fit various architectural designs and requirements. Construction teams can now produce sections that are pre-curved or angled to meet specific project needs, thus reducing installation time and labor costs. Additionally, since the bending process is conducted cold, there is minimal risk of altering the acoustic properties of the materials, ensuring that the barriers perform effectively against noise pollution.

The machine’s versatility extends beyond bending; it can accommodate a wide range of materials, including steel, aluminum, and composite materials, providing the flexibility needed in modern construction. Moreover, advancements in technology have led to the integration of computer numerical control (CNC) systems in these machines, allowing for precise measurements and complex designs that were not possible before.

As urban areas continue to expand and noise levels rise, the importance of effective acoustical barriers becomes even more pronounced. The cold bending machine not only contributes to the aesthetic and functional aspects of these structures but also plays a vital role in enhancing urban livability. By investing in advanced machinery like the cold bending machine, the construction industry can meet the growing demand for high-performance acoustical barriers, ultimately leading to quieter, more serene environments.

In conclusion, the acoustical barrier cold bending machine is a powerful tool that brings innovation to the construction industry. Its ability to shape materials precisely and efficiently is critical in the fight against noise pollution, contributing to healthier and more peaceful urban living.