Understanding AASHTO M180 and Cold Bending Machines in Highway Engineering

The development of reliable infrastructure is crucial for any nation’s progress, particularly in the context of transportation. Among the myriad of standards established for assessing the performance and safety of road construction materials, the AASHTO M180 specification plays a pivotal role, particularly for cold bending machines used to test the ductility and flexibility of materials like asphalt and steel.

What is AASHTO M180?

AASHTO M180, published by the American Association of State Highway and Transportation Officials (AASHTO), specifically pertains to the requirements for cold bending machines used in transportation engineering. This standard outlines the operational procedures and performance criteria essential for evaluating the integrity of materials that are subjected to bending forces. High-quality construction materials must exhibit adequate ductility to withstand various loads that highways endure.

The Importance of Cold Bending Machines

Cold bending machines are integral tools in material testing, particularly for road construction. They provide a controlled environment to evaluate how materials behave under stress without the application of heat. This is crucial because most road materials, like asphalt mixtures, are expected to perform effectively at ambient temperatures and in diverse weather conditions.

The usage of a cold bending machine aligns with the AASHTO M180 standard, which ensures that engineers can reliably reproduce test conditions necessary for accurate assessment. Such testing is critical for ensuring that construction materials meet safety and performance specifications before being utilized in highway projects.

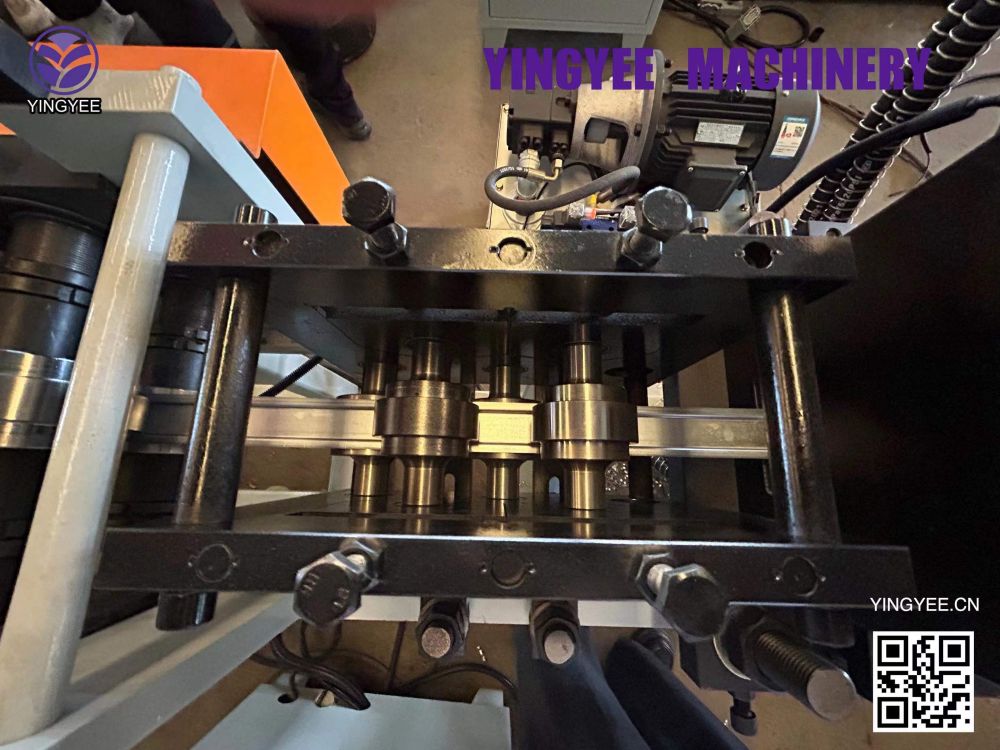

Design and Operation of Cold Bending Machines

Cold bending machines are designed to apply bending stress on materials uniformly and consistently. They typically consist of loading mechanisms, a support frame, and data recording systems to capture the material’s response under stress. The AASHTO M180 specifies the construction and operation of these machines to ensure uniformity and repeatability in testing processes across different laboratories.

The operational methodology usually involves placing a specimen in the machine, applying a specific load, and measuring the deflection or failure point of the material. These measurements are critical for calculating various mechanical properties, such as modulus of elasticity and yield strength, which are essential for determining whether a material is suitable for use in highway construction.

Significance of Compliance with AASHTO M180

Adherence to AASHTO M180 not only guarantees that the materials used are of high quality but also fosters consistency in testing processes, which can vary significantly between different labs and geographical locations. Ensuring that all materials are evaluated using the same standards helps in establishing a level playing field for construction projects, ultimately promoting safety and reliability in highway infrastructure.

When materials do not comply with AASHTO M180, the ramifications can be significant. Poor quality materials can lead to early road deterioration, increased maintenance costs, and even accidents. Therefore, compliance is essential not just for regulatory needs but also for the overall safety and quality of highways.

The Future of Cold Bending Tests and AASHTO M180

As technology continues to advance, so do the methods and machinery used for material testing. The design and functionality of cold bending machines are increasingly incorporating digital technologies, such as automated data capture and analysis software. This shift promises to enhance accuracy and reduce human error in the testing process.

Furthermore, ongoing research into materials may lead to revisions of standards such as AASHTO M180, ensuring they stay relevant in the face of evolving engineering practices and materials science. The goal remains the same to ensure that our infrastructure can withstand the demands of modern transportation and provide safe passage for all users.

Conclusion

In summary, AASHTO M180 and cold bending machines are critical components of material testing in highway engineering. They ensure that the materials used are not only compliant with safety standards but are also capable of performing effectively in real-world conditions. As the demands on road infrastructure evolve, so will the standards and testing methodologies, keeping safety and quality at the forefront of transportation engineering.