The AASHTO M180 standard provides critical guidelines for the evaluation of the cold bending resistance of materials used in the construction of transportation infrastructure, particularly in the testing of metallic structures such as pipes, beams, and other components. The cold bending machine, designed in accordance with these specifications, plays a vital role in assessing the flexibility and ductility of these materials under stress.

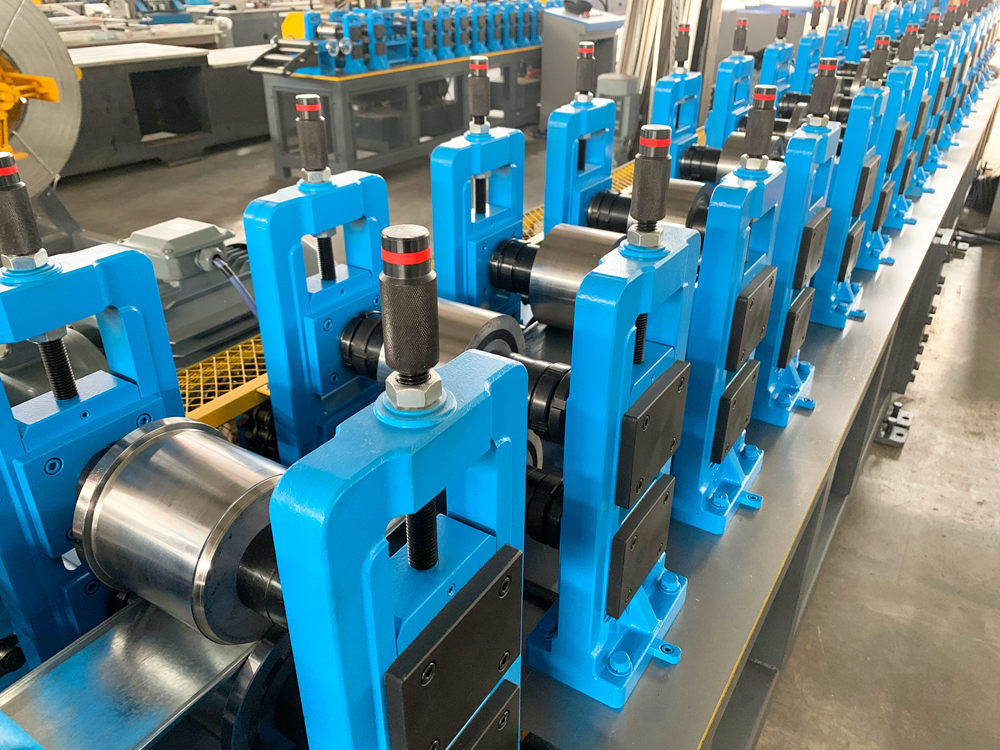

In accordance with AASHTO M180, the cold bending machine is equipped with precise measurement tools and hydraulic systems that facilitate uniform bending of the test specimens. The standard specifies the dimensions and tolerances for each test, ensuring that results are reliable and reproducible. The machine typically accommodates various sample sizes, allowing engineers to conduct multiple tests to gather extensive data.

The process begins with the preparation of the specimen, which is carefully cut and measured to meet the standard's specifications. The test is then conducted by securing the specimen in the machine and applying a specified bending force. The resistance of the material to this force is measured, providing insights into its mechanical properties such as yield strength, elasticity, and overall robustness.

Understanding the behavior of materials under cold bending conditions is paramount for design engineers. It aids in predicting how structures will perform throughout their lifespan, particularly under dynamic loads and environmental influences. Moreover, adhering to AASHTO M180 ensures that the materials used in construction meet safety requirements and industry standards, ultimately leading to safer and more reliable infrastructure.

In conclusion, the AASHTO M180 cold bending machine is an essential tool for evaluating the mechanical properties of construction materials. By providing accurate and standardized testing, it supports engineers in their quest to create resilient and durable structures that form the backbone of our transportation networks.