Understanding the AASHTO Guardrail Cold Bending Machine

In the realm of road safety and infrastructure, guardrails play a crucial role in protecting vehicles and passengers from accidents associated with road edges and embankments. A key component in the production of effective guardrails is the AASHTO (American Association of State Highway and Transportation Officials) Guardrail Cold Bending Machine. This innovative machinery has revolutionized the way guardrail components are manufactured and ensures that they meet stringent safety standards.

The Importance of Guardrails

Guardrails are essential for managing vehicle collisions, especially on highways and rural roads where sudden obstacles can pose significant risks. They are designed to redirect vehicles back onto the roadway, minimizing the likelihood of a rollover or collision with fixed objects. The design and structural integrity of guardrails are vital for their effectiveness. Hence, the materials used and the manufacturing processes involved—particularly the bending of guardrail sections—are of utmost importance.

What is AASHTO?

AASHTO provides guidelines and standards for the construction and maintenance of road infrastructure in the United States. Their specifications for guardrail systems include detailed requirements for performance, material quality, and installation techniques. The use of AASHTO standards ensures that guardrails not only fulfill legal obligations but also contribute to overall road safety and efficiency.

The Role of Cold Bending

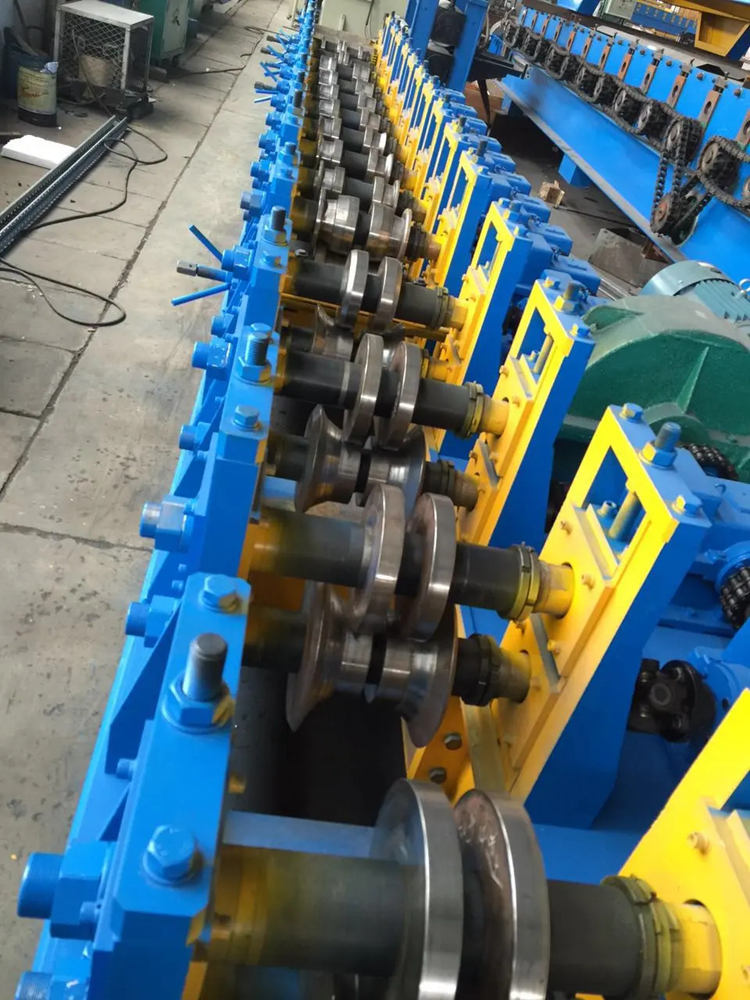

The primary function of the AASHTO Guardrail Cold Bending Machine is to bend guardrail sections at specific angles without the application of heat. Cold bending offers several advantages over traditional methods. Firstly, it allows for precise control over the curvature of the guardrail, ensuring that each piece meets the required specifications for strength and flexibility. This precision is critical, as improperly bent guardrails can lead to catastrophic failures during an impact.

Secondly, cold bending preserves the structural integrity of the metal. Heating metal can alter its molecular structure, potentially weakening it. By using cold bending techniques, manufacturers can retain the strength of the material while still achieving the necessary shapes.

Features of AASHTO Guardrail Cold Bending Machines

Modern cold bending machines designed according to AASHTO specifications are equipped with advanced technological features. These machines utilize CNC (Computer Numerical Control) technology to automate the bending process, allowing for rapid production with minimal human error. This technological advancement ensures consistency across multiple production runs and helps meet high demand with efficiency.

Furthermore, these machines are built with safety in mind. They incorporate protective features to safeguard operators during the bending process. The integration of user-friendly interfaces and real-time monitoring systems also enhances operational effectiveness.

Conclusion

The AASHTO Guardrail Cold Bending Machine is a critical tool in the production of guardrail systems that meet high safety standards. By enabling precise and controlled bending processes, this machine plays a significant role in ensuring that guardrail components adequately protect drivers and pedestrians alike. As road safety continues to be a priority within the transportation industry, investments in such advanced machinery will help enhance the overall integrity of our road networks. In turn, this advances AASHTO’s mission to promote safe and efficient transportation throughout the United States.