In the realm of infrastructure development and road safety, the demand for efficient and precise machinery has never been higher.

One such pivotal tool transforming the landscape is the AASHTO guardrail cold bending machine. This innovative piece of equipment caters to the need for durable and customized guardrails that meet stringent safety standards, ensuring reliability and longevity in diverse environmental conditions.

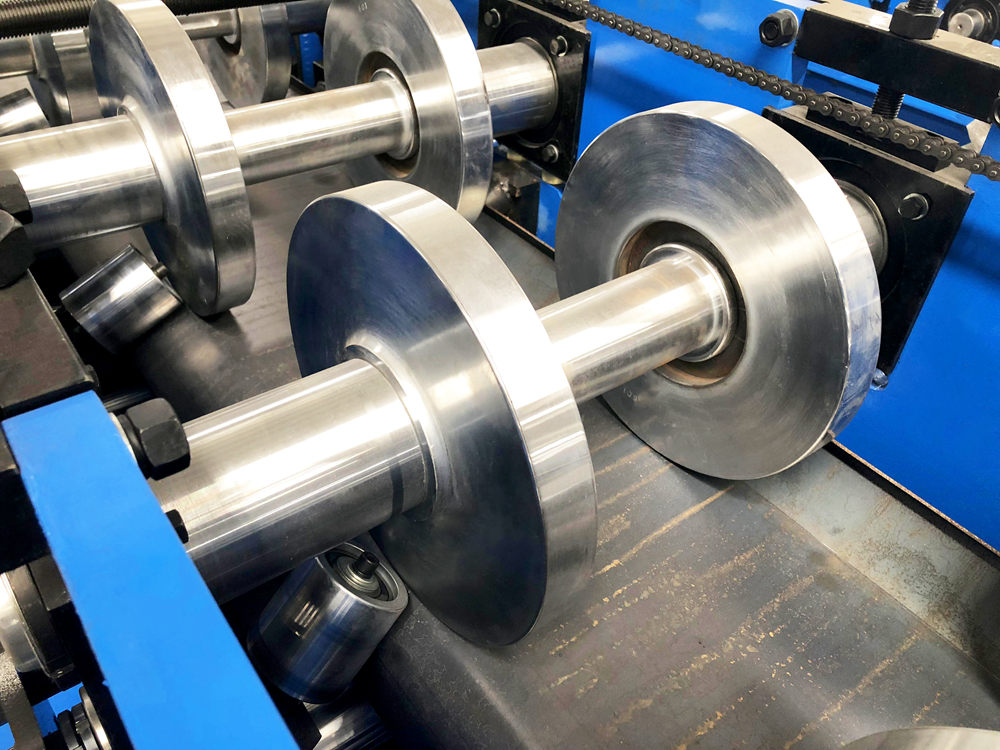

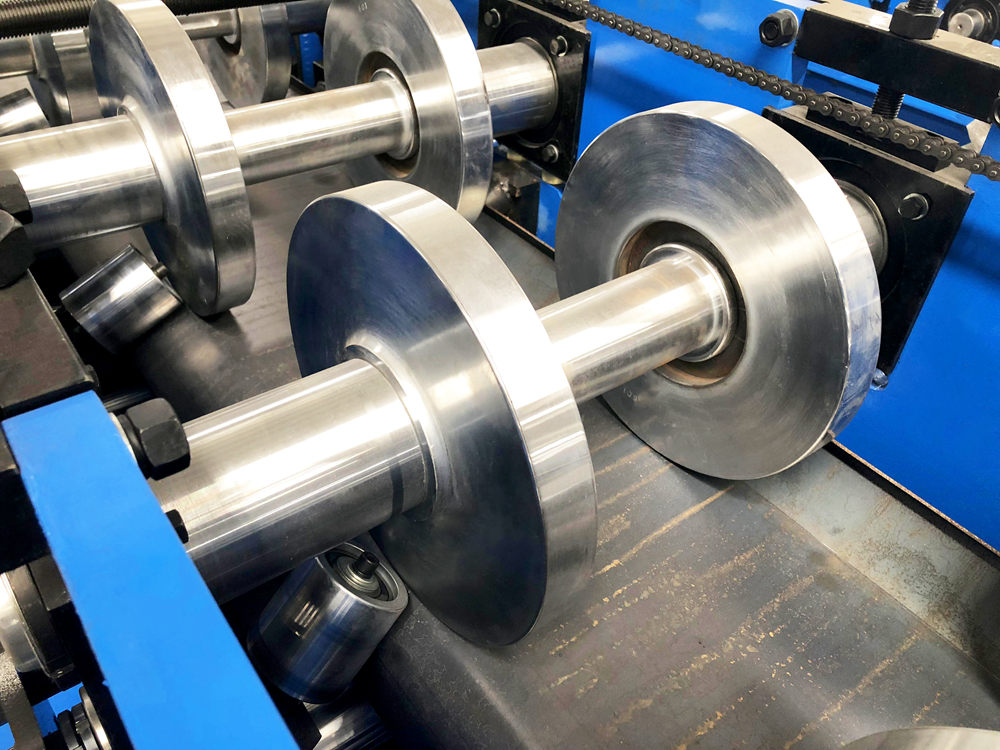

The AASHTO (American Association of State Highway and Transportation Officials) guardrail cold bending machine stands as a testament to engineering excellence, offering unmatched precision and flexibility in the fabrication of guardrails. Its advanced cold bending capability allows for the manipulation of metals without the application of heat, thereby preserving the structural integrity of the material. This cold bending process is particularly beneficial for ensuring that guardrails maintain their robustness and effectiveness over time, especially under the harsh conditions they often face.

Expertise in using this machine translates to numerous advantages for construction companies and safety regulators. From an operational standpoint, the AASHTO guardrail cold bending machine minimizes material wastage and enhances production efficiency. It is equipped with state-of-the-art control systems that allow operators to execute precise bends with minimal effort, ensuring that each guardrail piece adheres to exact specifications required for specific highway applications.

What sets this machinery apart in professional circles is its adaptability to different project requirements. The AASHTO standard mandates specific parameters for guardrail installations in terms of strength, flexibility, and durability. The guardrail cold bending machine excels in meeting these standards by providing customizable solutions that can accommodate varying design needs without compromising on safety or performance. This capability becomes particularly crucial when addressing unique or complex roadway designs, such as sharp curves or steep inclines, where standard guardrail designs may not suffice.

aashto guardrail cold bending machine

Establishing authority in the field of road safety equipment, manufacturers of the AASHTO guardrail cold bending machine are committed to continuous improvement, ensuring that their products remain at the forefront of technological advancement. This commitment to innovation is supported by rigorous testing and certification processes that guarantee the machine's compliance with international safety and quality standards. By partnering with industry leaders, these manufacturers ensure that their machines are built to last, backed by comprehensive support and expertise that instills confidence in their clients.

Trust is an indispensable component of the relationship between manufacturers and their clients. The AASHTO guardrail cold bending machine earns this trust through its proven track record of performance, underpinned by testimonies from satisfied users who have witnessed efficiency and safety improvements in their projects. These testimonials, coupled with robust after-sales service and training programs, enhance user confidence, enabling operators to maximize the potential of the machine safely and effectively.

In conclusion, anyone engaged in highway construction or maintenance must consider the AASHTO guardrail cold bending machine as a strategic investment. Its expert design and authoritative presence in the market uphold safety and efficiency as paramount values, ensuring that every installation not only meets but exceeds expectations. As technology continues to evolve, so too will the capabilities of this remarkable machine, reinforcing its status as an indispensable asset in road safety management.