The AASHTO Guardrail Cold Bending Machine Innovation in Highway Safety

Highway safety is a paramount concern for transportation agencies worldwide. Among the various measures adopted to enhance road safety, guardrails play a crucial role in protecting vehicles and their occupants from hazards. With the increasing demand for effective guardrail systems, the cold bending machine, designed in accordance with the American Association of State Highway and Transportation Officials (AASHTO) guidelines, has emerged as a vital component in the production and installation of guardrails. This article explores the significance, mechanics, and benefits of the AASHTO guardrail cold bending machine in improving highway safety.

Understanding Guardrails and Their Importance

Guardrails are designed to prevent vehicles from veering off the road, especially on curves, elevated terrains, and areas with fixed hazards like trees or utility poles. They act as a barrier, redirecting vehicles back onto the roadway, thereby reducing the risk of severe accidents. Given their critical role, the design and installation of guardrails must adhere to stringent safety standards, such as those outlined by AASHTO, ensuring that they can absorb impact effectively and redirect vehicles safely.

The Role of the Cold Bending Machine

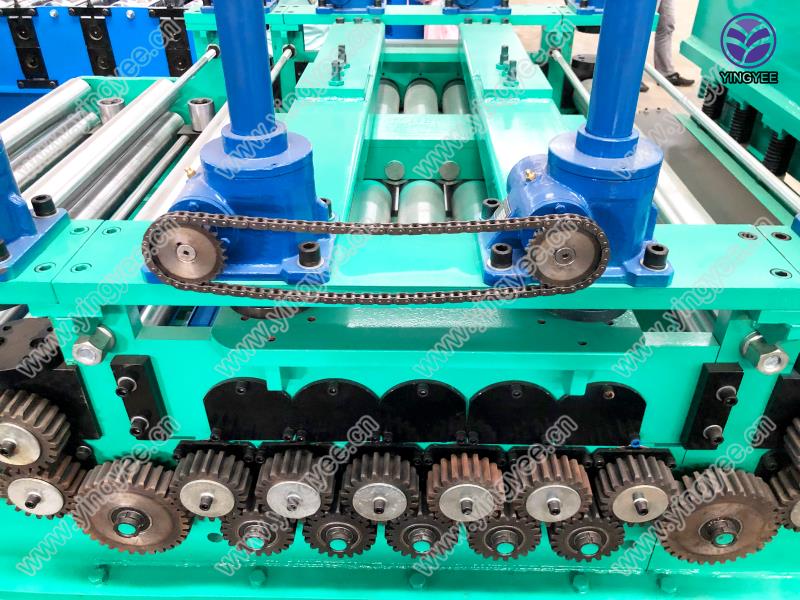

The AASHTO guardrail cold bending machine is specially engineered for the efficient shaping and bending of steel guardrail components. Cold bending refers to the process of bending metal without the application of heat, which preserves the steel’s structural integrity and strength. This method enables manufacturers to produce guardrail sections that are both durable and capable of withstanding substantial impact forces.

The cold bending machine operates by applying precise force to the guardrail material, allowing it to be shaped into the required profiles that meet AASHTO specifications. This ensures that the guardrails can perform effectively when tested against impact forces during real-world crash scenarios.

Key Features of the AASHTO Guardrail Cold Bending Machine

Several features of the AASHTO guardrail cold bending machine contribute to its efficiency and effectiveness

1. Customization The machine can bend guardrail sections into various shapes and angles, accommodating specific road designs and safety needs.

2. High Precision Advanced technology integrated into the machine allows for precise control over the bending process, resulting in consistent product quality.

4. Ease of Use Operators can easily set parameters and control the bending process, minimizing the learning curve and enhancing productivity.

5. Safety Standards Compliance The machine’s design and output adhere to AASHTO and other relevant safety standards, ensuring that the finished guardrails meet legal and safety requirements.

Benefits of Using the Cold Bending Machine

Utilizing an AASHTO guardrail cold bending machine offers numerous advantages for manufacturers and transportation agencies alike

- Enhanced Safety By producing high-quality, AASHTO-compliant guardrails, the machine directly contributes to reducing road accidents and saving lives.

- Cost-Effectiveness By streamlining the production process and ensuring minimal waste of materials, the cold bending machine becomes a valuable asset for manufacturers, leading to lower overall costs.

- Faster Production The machine's efficiency means that guardrail sections can be produced quickly, allowing for timely installations on highways and roads.

- Versatility It can accommodate different grades and types of steel, making it suitable for various guardrail designs.

Conclusion

The AASHTO guardrail cold bending machine stands at the forefront of modern highway safety technology. By ensuring the production of high-quality, durable, and effective guardrail systems, this machine plays a pivotal role in enhancing roadway safety. As transportation infrastructure continues to evolve, investing in innovative machinery like the cold bending machine is essential for meeting future challenges and ensuring the safety of road users. Through continuous improvements in guardrail design and manufacturing, we can look forward to safer roads and a reduced incidence of accidents in our communities.