The Importance of 50-600% Cable Tray Machines in Modern Construction

In the ever-evolving landscape of modern construction and electrical installations, cable management has become a crucial element of project planning and execution. Among the various solutions designed to enhance efficiency and safety, cable tray systems stand out as an essential component. This article explores the significance of 50-600% cable tray machines—machines capable of producing advanced cable trays that meet the diverse needs of various industries.

What are Cable Trays?

Cable trays are structures that support insulated electrical cables used for power distribution. They are designed to carry various types of cables, including communication and power wiring, providing a secure pathway for the organization and protection of these cables. Proper cable management is vital not only for safety but also for ease of maintenance and compliance with regulatory standards.

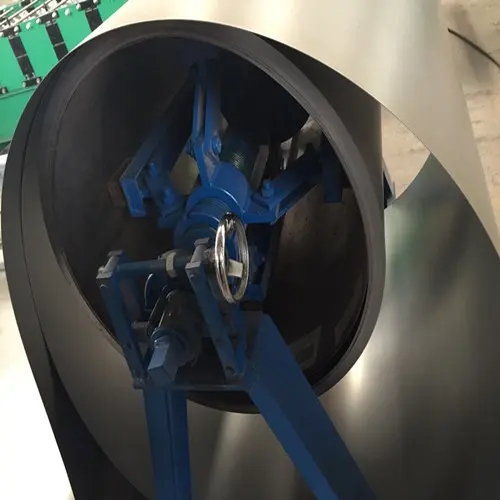

The Role of Cable Tray Machines

Cable tray machines facilitate the production of cable trays in varying sizes and designs. Machines that fall within the 50-600% production capacity range are particularly vital. These machines can produce trays in bulk, meeting the increasing demands for installation in commercial buildings, industrial plants, and infrastructure projects.

Efficiency and Flexibility

One of the primary advantages of using a 50-600% cable tray machine is enhanced efficiency. These machines are designed to operate at high speeds while maintaining consistent quality. By automating the production process, manufacturers can significantly reduce labor costs and decrease the time required to deliver cable trays to job sites. The ability to produce trays in bulk also means that contractors can order exactly what they need without unnecessary delays.

Flexibility is another essential feature of these machines. With the ability to produce various types of cable trays—such as ladder trays, perforated trays, and solid-bottom trays—manufacturers can cater to the specific requirements of different projects. This adaptability is crucial for meeting the unique challenges posed by different electrical systems and installation environments.

Quality and Safety Standards

Quality control is paramount when it comes to electrical installations. 50-600% cable tray machines are equipped with advanced technology to ensure the trays produced meet stringent safety and quality standards. These machines often include automated systems that monitor production for defects, ensuring that only top-quality products reach the market. This commitment to quality reduces the risk of system failures and ensures a safe environment for electrical installations.

Environmental Impact

Sustainability is an increasing concern in the construction industry. Many modern cable tray machines are designed to be energy-efficient, minimizing their environmental footprint during production. Additionally, some manufacturers are moving toward using recycled materials in their tray production processes. This commitment not only addresses environmental concerns but also aligns with global standards for reducing waste and promoting sustainable practices.

Market Growth and Future Perspectives

As construction continues to grow globally, the demand for effective cable management solutions will only increase. The market for cable tray machines, particularly those with a production capacity of 50-600%, is expected to expand significantly. Factors such as urbanization, infrastructural development, and the widespread adoption of renewable energy sources are driving this growth.

In conclusion, the introduction and innovation of 50-600% cable tray machines mark a pivotal shift in how cable management solutions are manufactured and implemented within the construction and electrical sectors. Their efficiency, flexibility, commitment to safety and quality, and lower environmental impact make them indispensable tools in modern construction. As technology continues to advance, these machines will play a crucial role in shaping the future of electrical installations, ultimately contributing to safer and more efficient systems worldwide.