The Evolution and Importance of Cable Tray Machines in Modern Infrastructure

In today's fast-paced world of technological advancements, the efficiency of electrical installations has never been more crucial. One essential element in this evolution is the cable tray machine, a device that has revolutionized how we manage and organize cable systems in commercial and industrial settings. Specifically, those that handle capacities ranging from 50% to 600% are noteworthy for their adaptability and efficiency.

Understanding Cable Tray Machines

Cable tray machines are essential for manufacturing cable trays — structures used to support insulated electrical cables. These trays come in various shapes and sizes, crafted to meet the specific needs of different projects. The primary purpose of a cable tray is to provide a pathway for electrical wiring, allowing for organized management and facilitating easy maintenance. The efficiency of these machines heavily influences the quality and speed of cable tray production.

The Working Principle

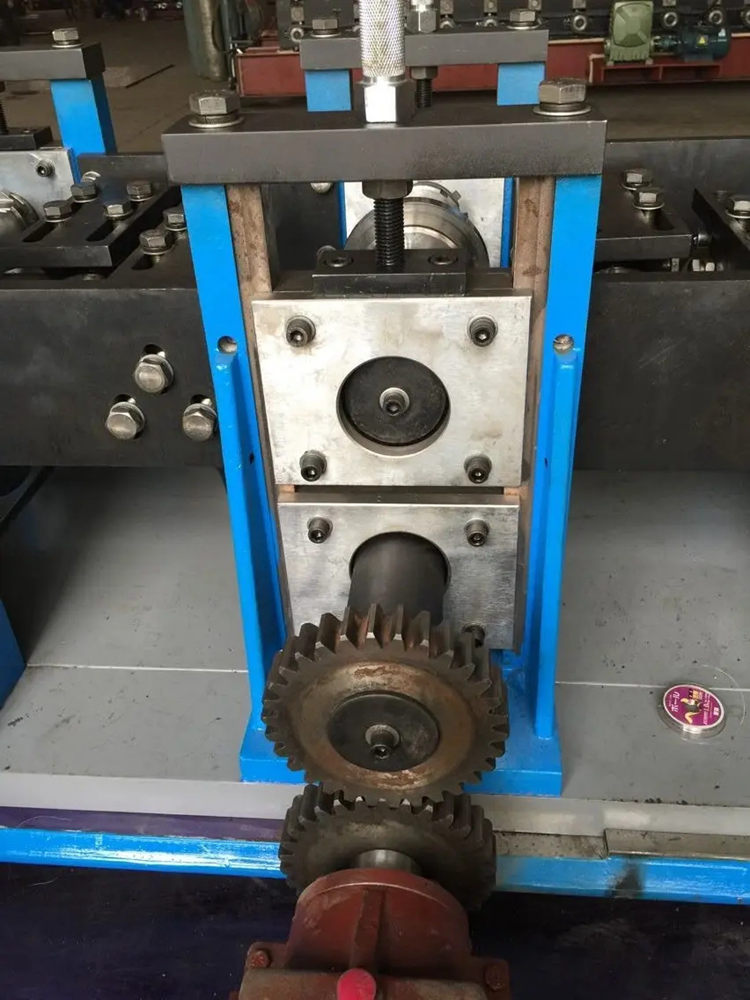

A cable tray machine typically consists of several components, including a feeding system, bending machine, and cutting mechanisms. These elements work in tandem to produce trays with varying widths and heights, enabling diversification in installation options. The process usually starts with rolling sheets of metal into the desired shape, followed by cutting them to specific lengths. Advanced models incorporate automated systems that enhance precision, reduce material waste, and improve overall productivity.

Capacity Versatility From 50% to 600%

The term '50-600%' refers to the machine’s ability to handle various capacities based on load requirements and environmental conditions. Cable trays designed for light loads (like 50%) are generally more suitable for indoor applications, where cable organization is critical for efficiency and aesthetics. On the other hand, trays designed to accommodate heavier loads (up to 600%) are more adaptable to industrial applications, often found in manufacturing plants, data centers, and utilities — places where robust cable management systems are necessary.

Benefits of High-Capacity Cable Tray Machines

1. Increased Production Efficiency Given the broad capacity range, businesses can generate a large volume of trays in a relatively short period. This scalability meets the growing demands of infrastructure development without compromising on quality.

2. Cost-Effectiveness Investing in machines that can handle multiple capacities allows companies to reduce the need for separate equipment. This consolidation not only saves on upfront costs but also on maintenance and operational expenses.

3. Enhanced Customization Modern cable tray machines often allow for customization in design and size. This flexibility is particularly beneficial in unique projects where standard trays may not suffice.

4. Improved Durability and Safety Machines capable of producing higher-capacity trays ensure that the end products are robust and reliable. This is crucial in industries where the safety of electrical installations cannot be compromised.

Application in Various Sectors

The implications of cable tray machines extend beyond mere electrical installations. For instance, in the telecommunications sector, they help in organizing the significant cables necessary for network infrastructure. In healthcare, they facilitate the management of cables used in medical equipment, ensuring a clutter-free environment critical to patient safety. Moreover, as renewable energy sources like solar and wind become more prevalent, these machines play a vital role in organizing the complex wiring systems that power our future.

Conclusion

The evolution of cable tray machines, particularly those with capacities ranging from 50% to 600%, reflects a broader trend towards automation and efficiency in the construction and electrical industries. As these machines continue to advance, they are set to play an integral role in shaping the infrastructure of tomorrow. By providing enhanced organization, accessibility, and safety for electrical installations, cable tray machines are not just tools; they are an essential component in the ongoing quest for innovation and excellence in cable management systems. Acknowledging their importance could lead to smarter investments in technology, ultimately benefiting companies and communities alike.