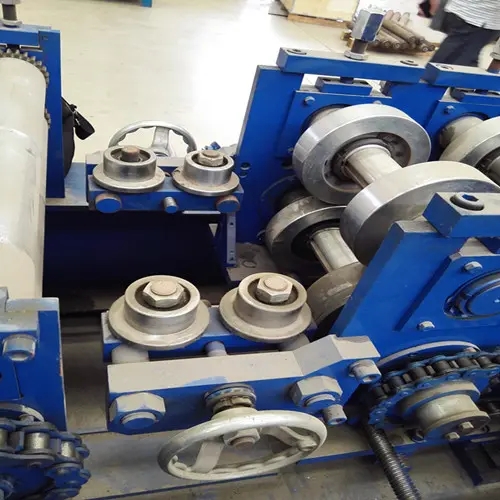

The Omega Track Roll Forming Machine Ensuring Consistent Length and No Twist

In the realm of metal processing, the Omega Track Roll Forming Machine stands out for its exceptional ability to produce tracks with consistent length and no twist. This advanced machinery is designed to handle a wide range of materials, including steel, aluminum, and copper, making it an indispensable tool for manufacturers in various industries.

One of the key features that sets the Omega Track Roll Forming Machine apart from its competitors is its precision engineering. The machine is equipped with high-quality rollers that are precisely aligned to ensure that the material being formed undergoes a uniform deformation process. This results in tracks with consistent dimensions, which is crucial for ensuring the functionality and performance of the final product.

Another significant advantage of the Omega Track Roll Forming Machine is its ability to prevent twist during the forming process. This is achieved through the use of specialized roller designs and control systems that monitor and adjust the tension of the material as it passes through the machine. By maintaining a constant tension, the machine ensures that the track maintains its straightness and alignment, resulting in a high-quality final product.

The versatility of the Omega Track Roll Forming Machine is another notable aspect

The versatility of the Omega Track Roll Forming Machine is another notable aspect

The versatility of the Omega Track Roll Forming Machine is another notable aspect

The versatility of the Omega Track Roll Forming Machine is another notable aspect

omega track roll forming machine with consistent length and no twist

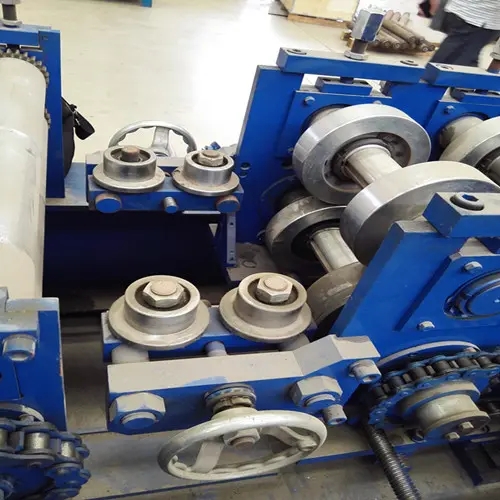

omega track roll forming machine with consistent length and no twist. It can be easily adjusted to accommodate different track sizes and shapes, making it suitable for a wide range of applications. Whether you need to produce tracks for construction equipment, agricultural machinery, or any other type of vehicle, the Omega Track Roll Forming Machine has the capabilities to meet your specific requirements.

Furthermore, the machine is designed with user-friendly controls and a compact footprint, making it easy to operate and integrate into existing production lines. Its rugged construction and low maintenance requirements ensure that it can withstand the rigors of continuous operation, providing long-lasting performance and reducing downtime.

In conclusion, the Omega Track Roll Forming Machine represents a significant advancement in the field of metal processing. Its ability to produce tracks with consistent length and no twist, combined with its versatility and ease of use, makes it an invaluable asset for manufacturers seeking to improve their productivity and product quality. With its precision engineering and robust construction, the Omega Track Roll Forming Machine is sure to stand the test of time and continue to set new standards in the industry.

The versatility of the Omega Track Roll Forming Machine is another notable aspect

The versatility of the Omega Track Roll Forming Machine is another notable aspect

The versatility of the Omega Track Roll Forming Machine is another notable aspect

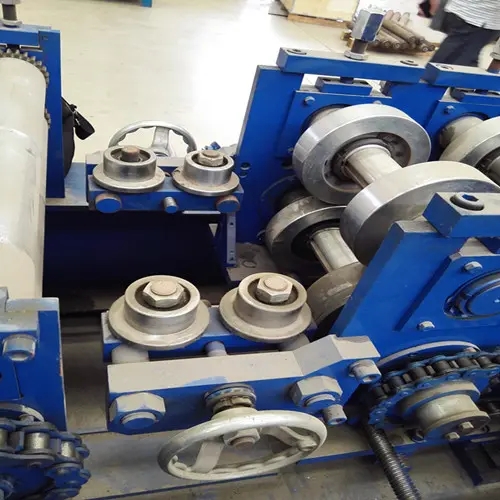

The versatility of the Omega Track Roll Forming Machine is another notable aspect omega track roll forming machine with consistent length and no twist. It can be easily adjusted to accommodate different track sizes and shapes, making it suitable for a wide range of applications. Whether you need to produce tracks for construction equipment, agricultural machinery, or any other type of vehicle, the Omega Track Roll Forming Machine has the capabilities to meet your specific requirements.

Furthermore, the machine is designed with user-friendly controls and a compact footprint, making it easy to operate and integrate into existing production lines. Its rugged construction and low maintenance requirements ensure that it can withstand the rigors of continuous operation, providing long-lasting performance and reducing downtime.

In conclusion, the Omega Track Roll Forming Machine represents a significant advancement in the field of metal processing. Its ability to produce tracks with consistent length and no twist, combined with its versatility and ease of use, makes it an invaluable asset for manufacturers seeking to improve their productivity and product quality. With its precision engineering and robust construction, the Omega Track Roll Forming Machine is sure to stand the test of time and continue to set new standards in the industry.

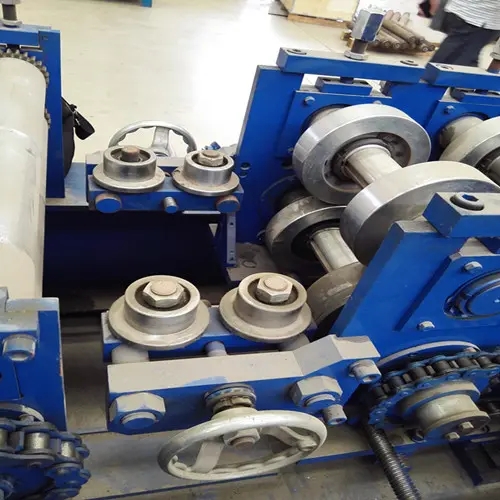

omega track roll forming machine with consistent length and no twist. It can be easily adjusted to accommodate different track sizes and shapes, making it suitable for a wide range of applications. Whether you need to produce tracks for construction equipment, agricultural machinery, or any other type of vehicle, the Omega Track Roll Forming Machine has the capabilities to meet your specific requirements.

Furthermore, the machine is designed with user-friendly controls and a compact footprint, making it easy to operate and integrate into existing production lines. Its rugged construction and low maintenance requirements ensure that it can withstand the rigors of continuous operation, providing long-lasting performance and reducing downtime.

In conclusion, the Omega Track Roll Forming Machine represents a significant advancement in the field of metal processing. Its ability to produce tracks with consistent length and no twist, combined with its versatility and ease of use, makes it an invaluable asset for manufacturers seeking to improve their productivity and product quality. With its precision engineering and robust construction, the Omega Track Roll Forming Machine is sure to stand the test of time and continue to set new standards in the industry.