Understanding the 1-3mm Cable Tray Roll Forming Machine

In the modern manufacturing landscape, efficiency and precision are paramount. One of the essential pieces of equipment that have made significant advancements in recent years is the cable tray roll forming machine. Particularly, the 1-3mm cable tray roll forming machine stands out for its capability to produce cable trays perfect for electrical wiring management in construction and industrial applications.

What is a Cable Tray Roll Forming Machine?

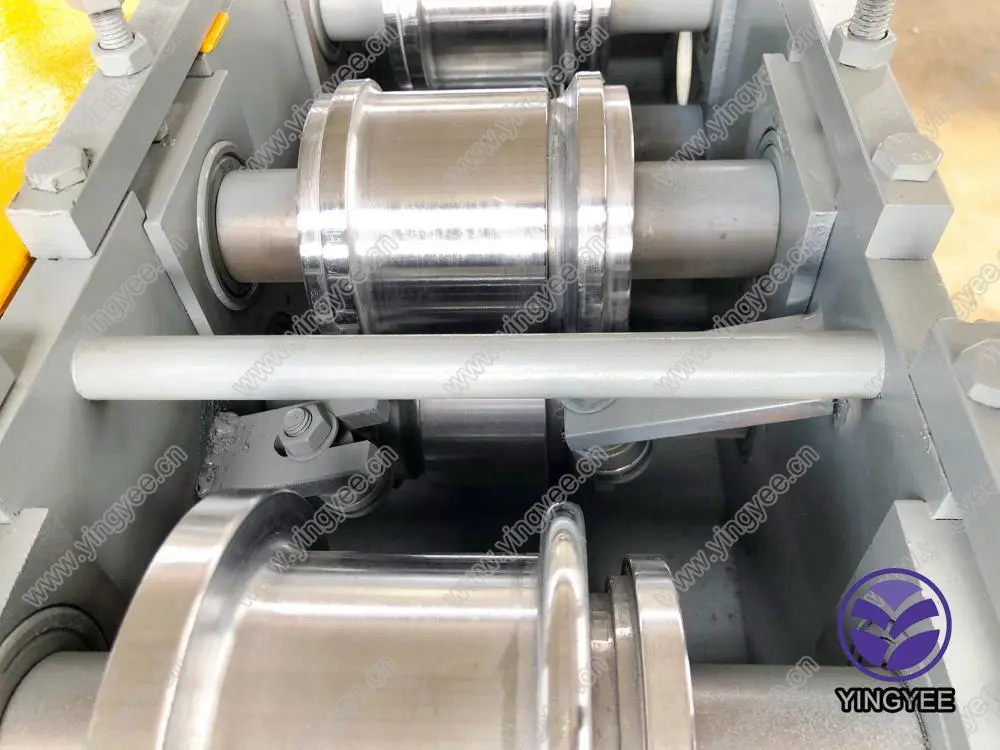

A cable tray roll forming machine is a specialized piece of equipment that fabricates metal strips into cable trays, which are used to support insulated cables. The roll forming process involves feeding metal sheets through a series of rollers that gradually shape the metal into the desired form. This method offers high production efficiency and excellent accuracy, making it an ideal choice for manufacturers looking to produce high-quality cable trays at scale.

Features of the 1-3mm Cable Tray Roll Forming Machine

The 1-3mm cable tray roll forming machine is specifically designed to handle metal sheets with thicknesses ranging from 1mm to 3mm. This thickness range is optimal for producing sturdy cable trays that can support heavy loads of electrical cabling in both indoor and outdoor applications.

1. Robust Construction These machines are made from high-strength materials that ensure longevity and durability. The robust design can handle the demands of continuous operation in industrial environments.

2. Precision Engineering With advanced computer numerical control (CNC) systems, the roll forming machine offers exceptional accuracy in shaping metal, ensuring that the produced trays comply with industry standards.

4. High Production Efficiency The machine operates at high speeds, allowing manufacturers to produce large quantities of cable trays in a relatively short time, thereby maximizing productivity and minimizing labor costs.

5. User-Friendly Interface Modern machines often come equipped with intuitive control panels that make it easier for operators to set up and adjust parameters for different production runs.

Applications of Cable Trays

Cable trays produced by these machines are widely used in various sectors

- Construction In buildings, cable trays are essential for organizing and protecting electrical wiring networks. - Telecommunications They are crucial in data centers and telecom facilities for managing extensive cabling systems. - Industrial Manufacturing plants utilize cable trays for efficient wiring management, reducing the risk of cable damage and fire hazards. - Transportation From subways to airports, these trays help organize the complex electrical systems required for modern transport infrastructure.

Advantages of Using a 1-3mm Cable Tray Roll Forming Machine

Investing in a cable tray roll forming machine offers numerous advantages

- Cost-Effectiveness By producing in-house, manufacturers can significantly reduce their material and labor costs. - Quality Control In-house production allows for better quality control, ensuring that the trays meet specific requirements and standards. - Customization It allows for easier customization, enabling manufacturers to meet the unique demands of each project efficiently.

Conclusion

The 1-3mm cable tray roll forming machine represents a technological advancement in metal fabrication. With its robust features, high efficiency, and the ability to produce custom designs, it is an invaluable tool for manufacturers in various industries. As the demand for organized electrical installations continues to grow, these machines will play a crucial role in meeting industry needs while enhancing safety and efficiency in electrical management. Investing in a cable tray roll forming machine can be a game-changer for manufacturers looking to optimize their production processes and deliver high-quality products to the market.