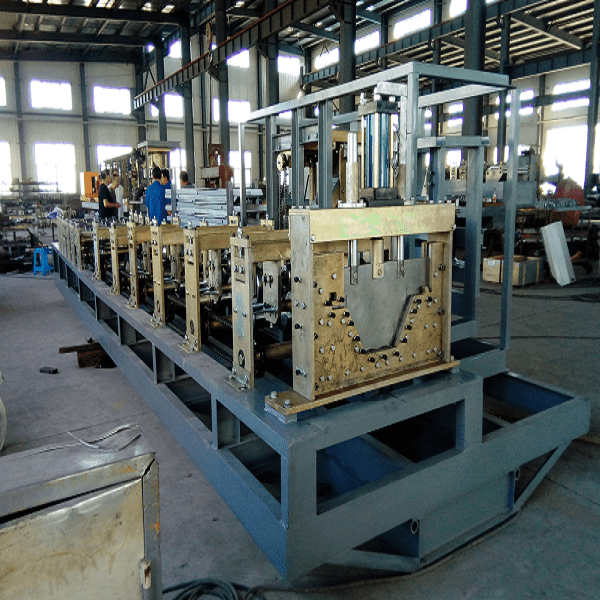

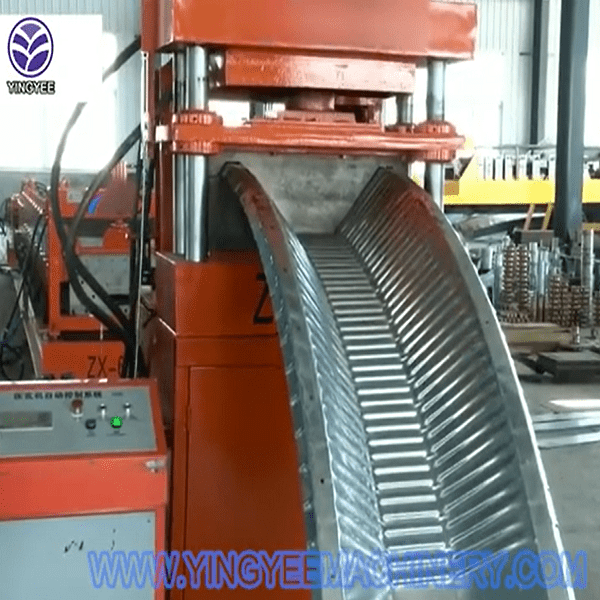

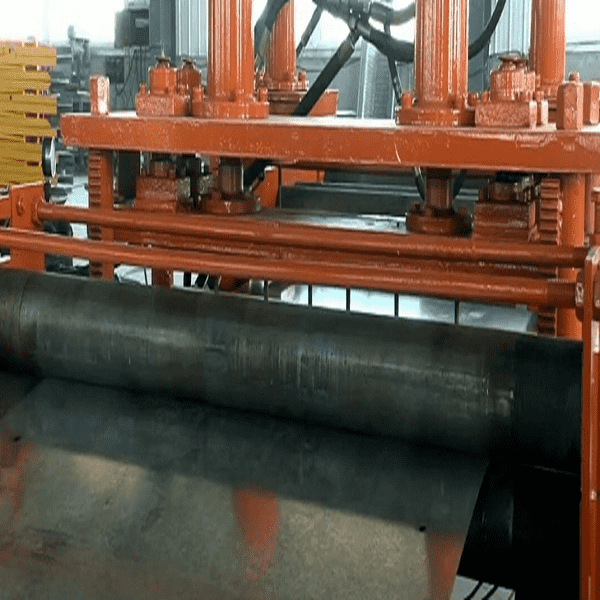

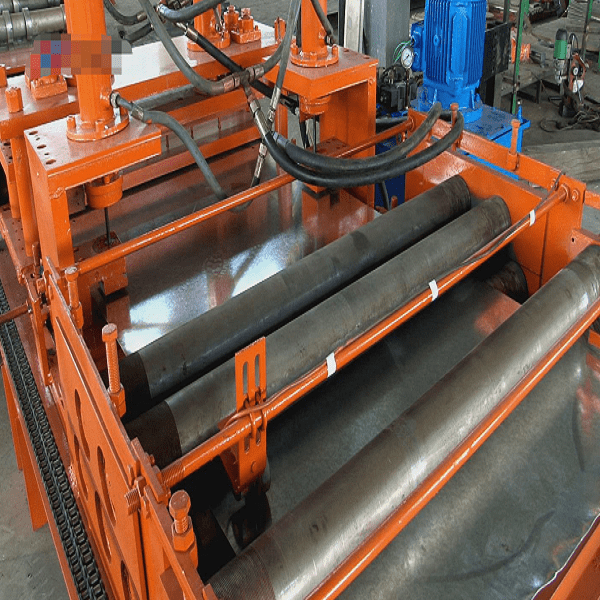

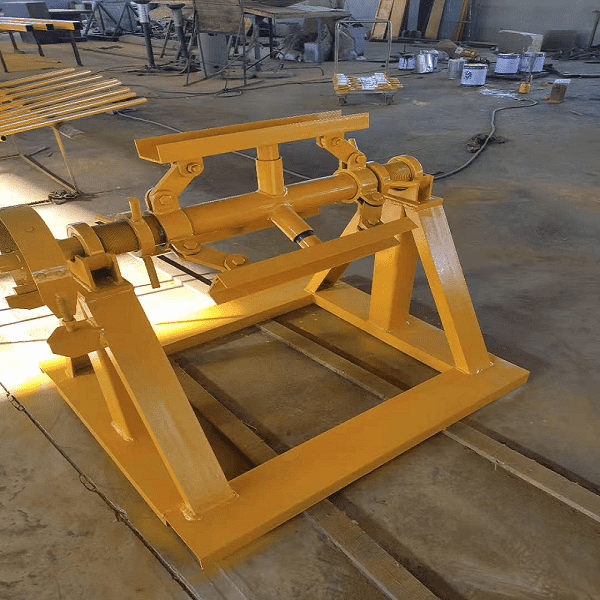

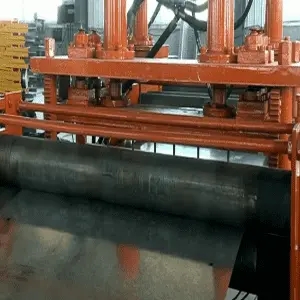

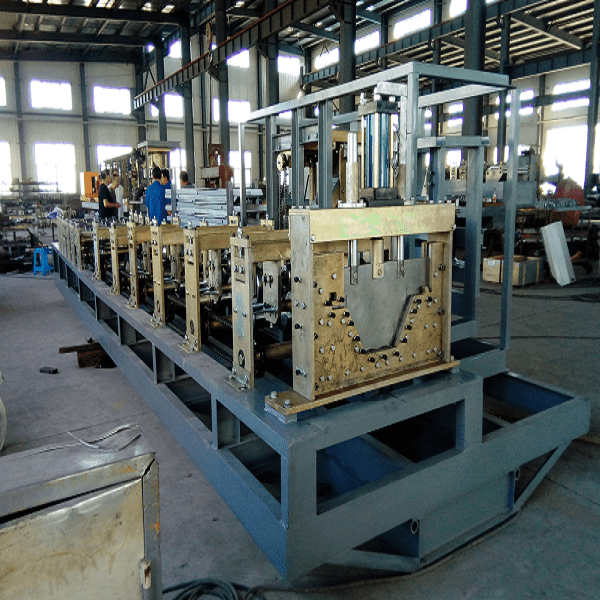

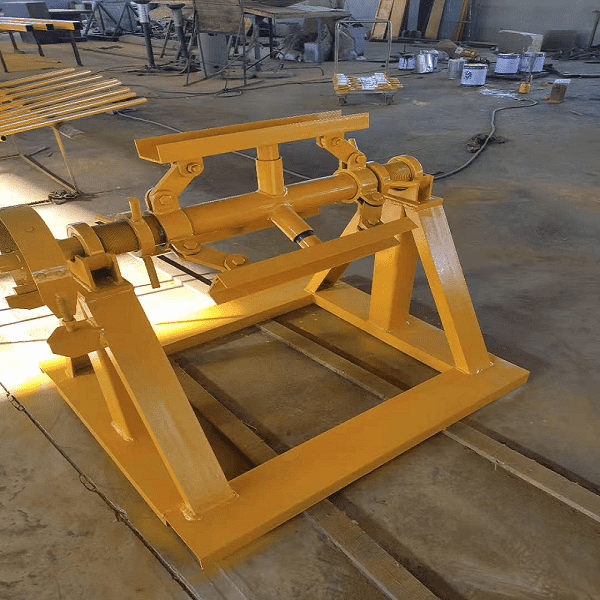

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Nga ahuatanga

1.1 Ko nga roera he mea hanga mai i te rino ma pai kua tukatukahia me te oro.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 Ka tino nui te tae kua oti whanganga, te kowakawaka teitei, te kaha o te taumahatanga.

2. Raraunga hangarau matua o YY-680:

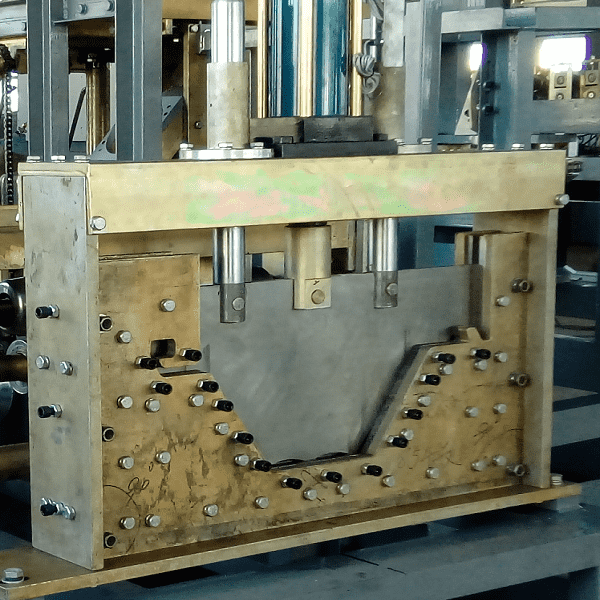

1. Punching part Size: 2900mmx1400mmx1300mm

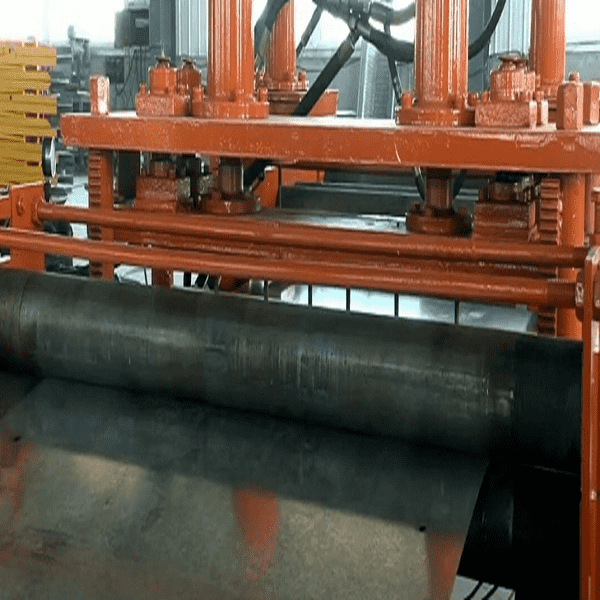

Te rahi o te waahanga panui tika: 10000mmx1400mmx1600mm

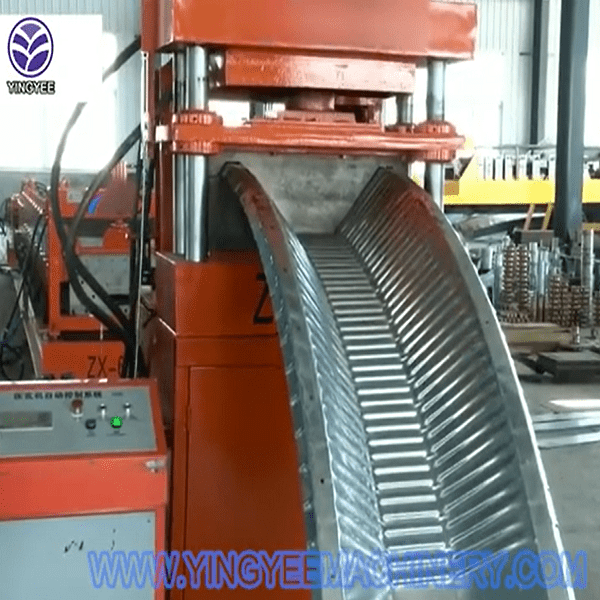

Te rahi o te waahanga o te roopu piko: 1600mmx1300mmx2500mm

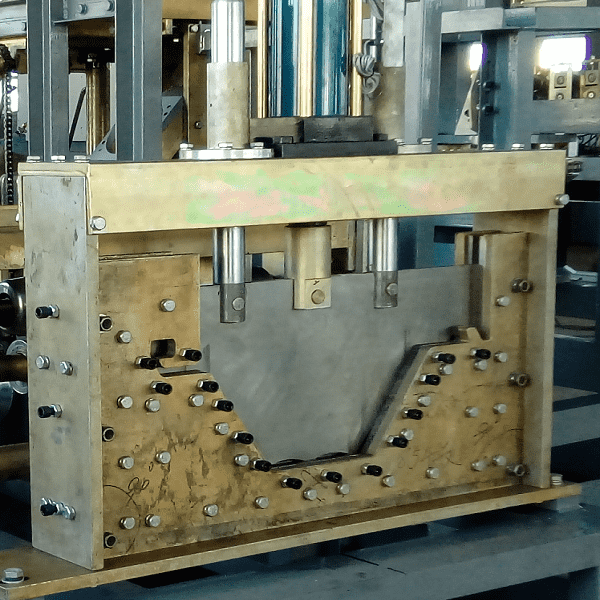

Oil pump part size: 1200mmx1200mmx1400mm

2. Te taumaha katoa: Mo te 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Te Mana Hanga: 7.5kw

6. Te Mana Whakapiko: 7.5kw

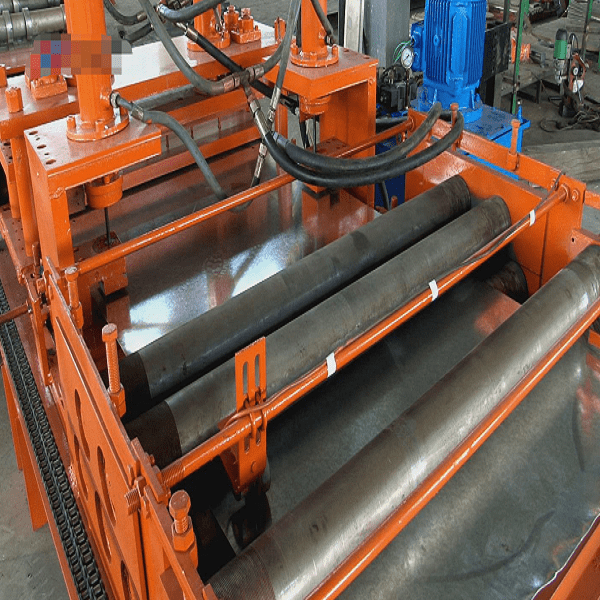

7. Mana Tapahi: 3.0kw

8. Oil papu mana motopaika:7.5kw

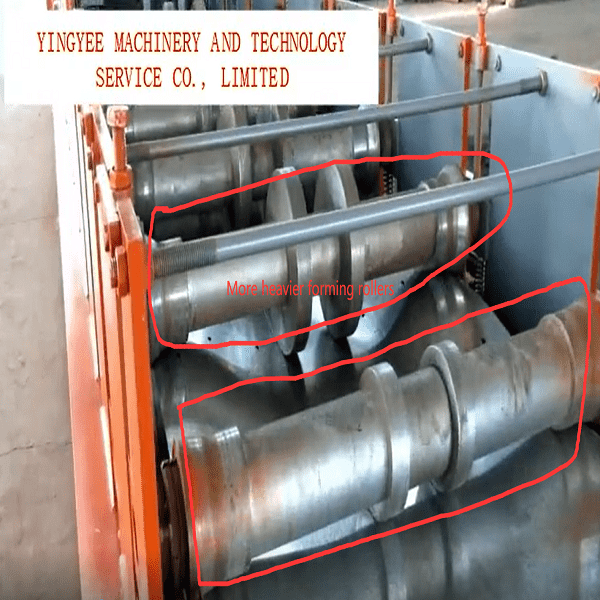

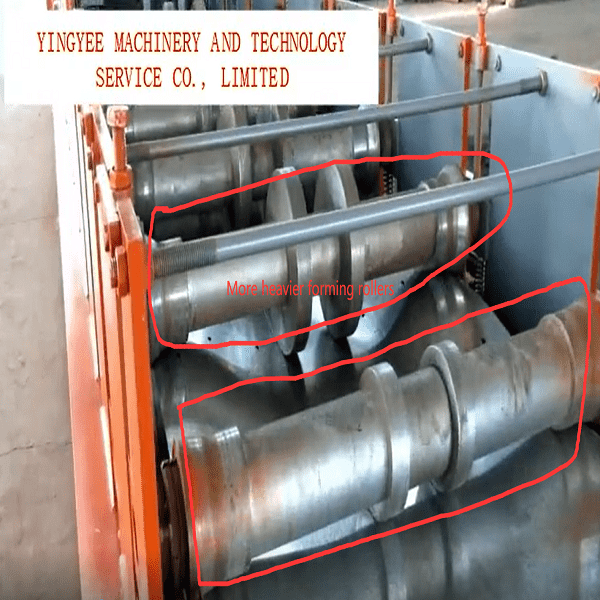

9. Rauemi o roera: 45# maitai, tineia HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Rauemi o te tapahi mata: Cr12Mov maitai

12. Step of rollers: 16 steps

13. Whānui Whāngai: 1000mm.

14. Effective Width: 680mm as drawing

15. Te matotoru o te porowhita: 0.6-1.6mm

16. Te hohonu o te riu: rite ki nga tuhi

17. roanga teitei:42 m

18.Taenga whakahaere o te röpü: 64%