In the fast-paced world of fastener manufacturing, precision and efficiency are non-negotiable. YingYee Machinery's thread rolling machine delivers unparalleled performance in producing high-quality threaded components with exceptional accuracy and durability. Our advanced cold-forming technology creates perfect threads through a pressure-forming process that enhances material strength while maintaining tight tolerances.

The thread rolling machine is engineered for reliability and productivity, capable of processing a wide range of materials including carbon steel, stainless steel, aluminum, and specialty alloys. Unlike cutting methods that remove material, our thread rolling process displaces metal to form threads, resulting in superior fatigue resistance and longer component life. This makes our machine ideal for producing critical fasteners used in automotive, aerospace, construction, and industrial applications where thread integrity is paramount.

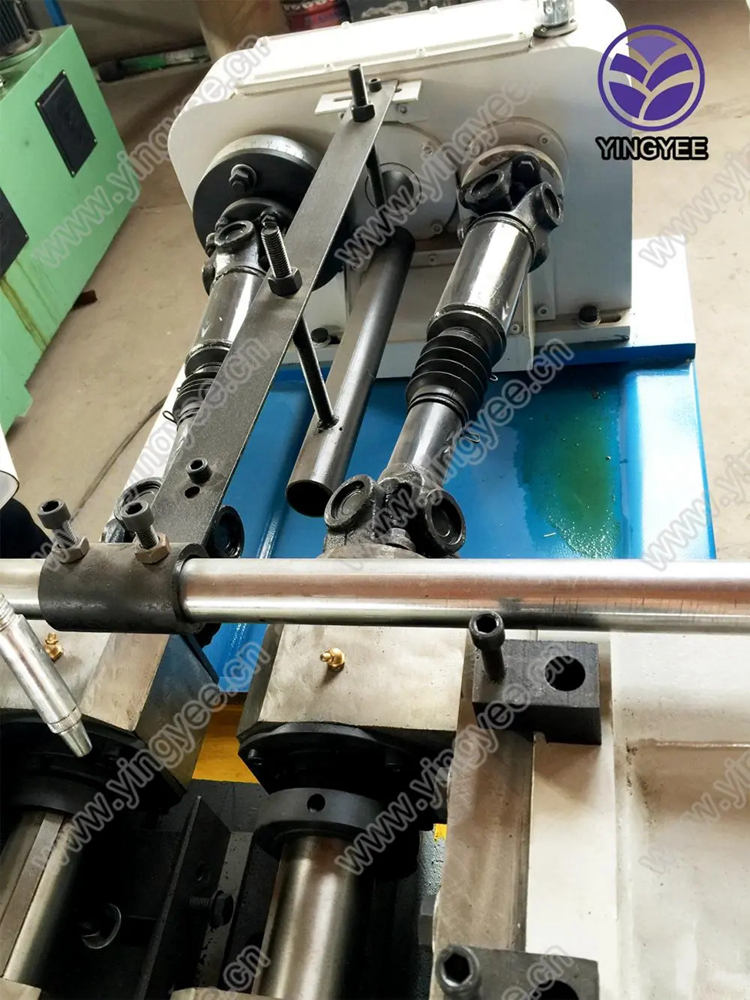

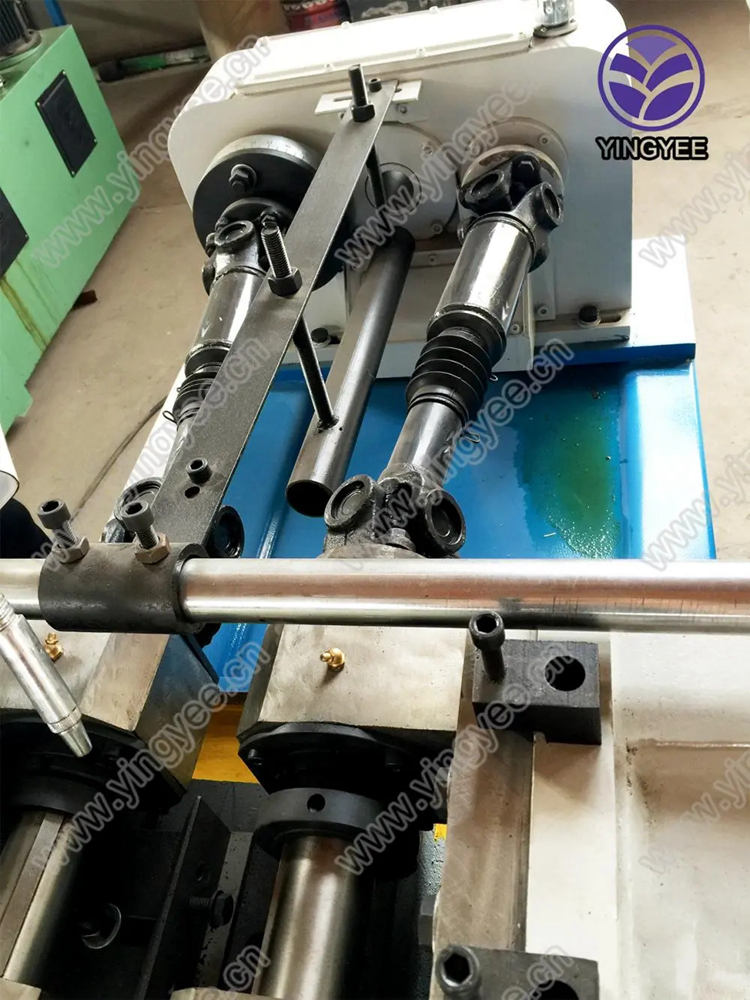

Vītņu ruļļu mašīna dažādu izmēru un veidu stieņiem. Atkarībā no sagataves veida trīs asu vītņu velmēšanas mašīnu izmanto dobu tērauda cauruļu apstrādei, un divu asu vītņu velmēšanas mašīnu izmanto cieto tērauda stieņu apstrādei.

Vītņu ruļļu formēšanas mašīna, mēs varam izgatavot vairākus materiālus

Atbilstoši materiālu veidam trīs asu vītņu velmēšanas mašīnu izmanto dobu tērauda cauruļu apstrādei, un divu asu vītņu velmēšanas mašīnu izmanto cieto tērauda stieņu apstrādei.

YingYee Machinery's thread rolling machine revolutionizes thread production by offering significant advantages over conventional threading techniques. The cold-forming process not only improves material strength by up to 30% through work hardening but also achieves production speeds up to five times faster than thread cutting. This combination of quality and efficiency translates directly to higher profitability for manufacturers.

For manufacturers requiring flexibility, our thread rolling machine accommodates various thread types including metric, unified, ACME, and special profiles. Quick-change die systems minimize setup time between production runs, allowing businesses to respond rapidly to changing customer requirements. These features make our machine an indispensable asset for fastener producers looking to enhance their competitive edge in global markets.

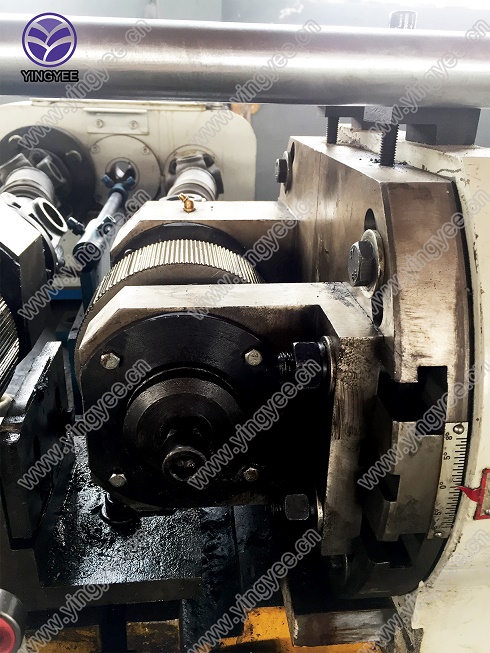

YingYee Machinery's thread rolling machine incorporates cutting-edge innovations to deliver unmatched performance in thread production. The machine features a heavy-duty frame construction with precision-guided slideways that maintain perfect die alignment under high forming pressures. This robust design ensures consistent thread quality while withstanding the rigors of continuous industrial operation.

The heart of our machine lies in its advanced control system, which precisely regulates forming pressure, feed speed, and synchronization between dies. Programmable settings allow operators to store parameters for different thread specifications, enabling quick changeovers and repeatable accuracy. Real-time monitoring systems track production quality and provide immediate feedback, allowing for adjustments before non-conforming parts are produced.

For specialized applications, our thread rolling machine offers optional features such as automatic loading systems, vision inspection integration, and marking capabilities. These technological enhancements enable manufacturers to create complete, value-added threaded components in a single operation, streamlining production workflows and reducing handling costs.

Investing in YingYee Machinery's thread rolling machine represents a strategic opportunity to grow your fastener manufacturing business. The machine's high production capacity enables you to take on larger contracts while maintaining the tight tolerances demanded by premium markets. By bringing thread rolling in-house, you gain greater control over quality and delivery schedules, enhancing your reputation as a reliable supplier.

As industries increasingly recognize the advantages of rolled threads over cut threads, our thread rolling machine positions your business to meet this growing demand. From standard fasteners to specialized threaded components, this versatile machine becomes the cornerstone of your production capabilities. Contact YingYee Machinery today to discover how our thread rolling solutions can transform your manufacturing operations and help you secure a stronger position in the competitive global fastener market.