Vertical Large Span Roll Forming Machine Revolutionizing the Metal Fabrication Industry

In the world of metal fabrication, the demand for efficiency, precision, and versatility continues to grow. Among the innovative solutions designed to meet these industrial needs is the vertical large span roll forming machine. This advanced equipment plays a pivotal role in producing high-quality metal profiles used in a range of applications, from construction to transportation.

A vertical large span roll forming machine operates using a continuous and automated process that transforms flat metal sheets into specific shapes and sizes. The design of this machine allows for the formation of large sections with exceptional accuracy. The vertical configuration of the machine provides several benefits, including improved material handling, reduced floor space requirements, and enhanced stability during the forming process.

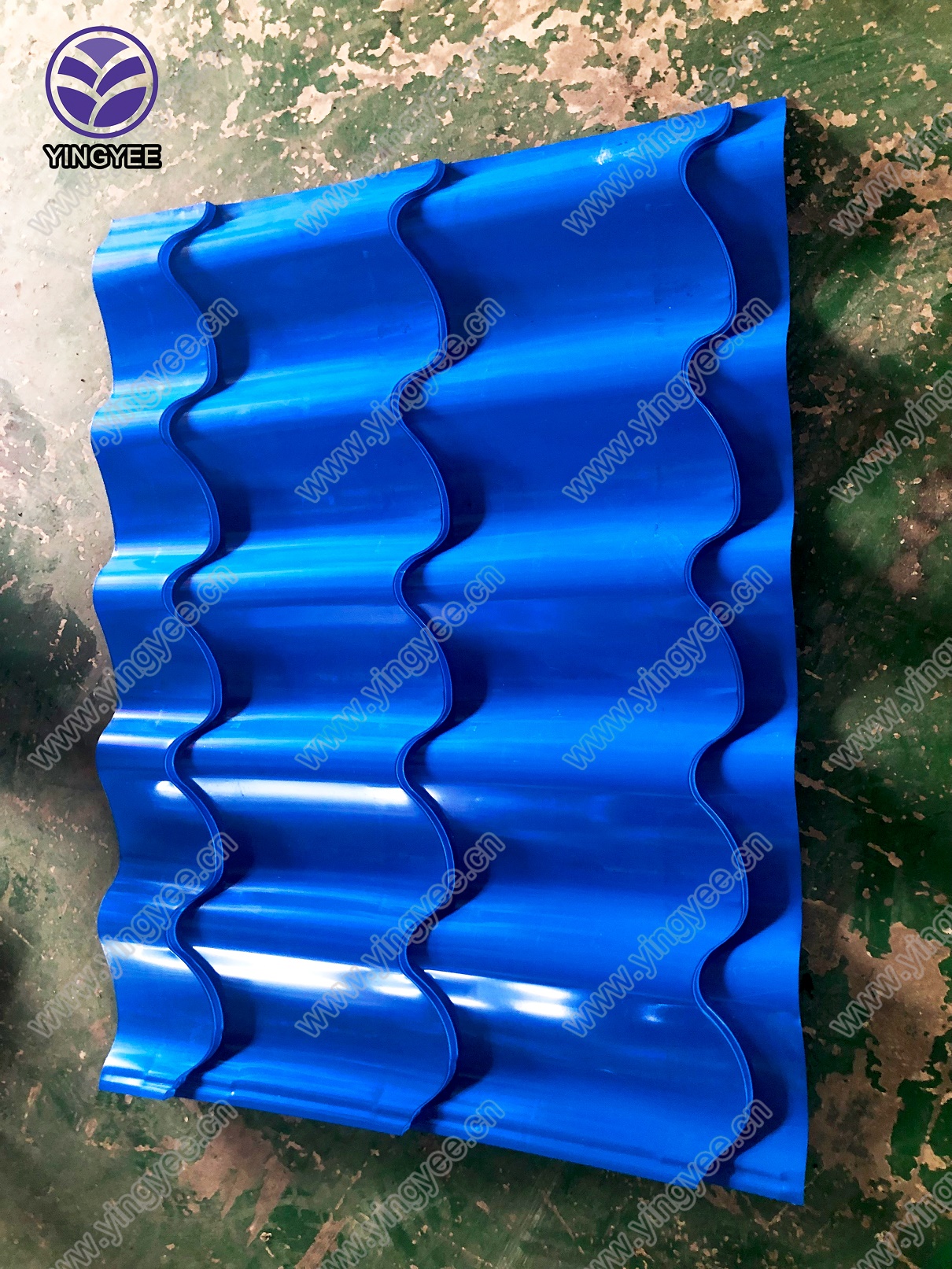

One of the standout features of vertical large span roll forming machines is their ability to create complex profiles without compromising on strength or durability. This is particularly important in industries where structural integrity is paramount, such as in building facades, roofing systems, and even specialized equipment. The machine can produce various profiles, including C-sections, Z-sections, and more, tailored to meet specific project requirements.

Moreover, the automation capabilities of modern roll forming machinery contribute significantly to operational efficiency. With advanced digital controls and sensors, manufacturers can achieve precise speed and pressure settings, minimizing material waste and ensuring consistent quality across all products. This high level of automation allows for faster production cycles, enabling companies to meet tight deadlines without sacrificing quality.

The versatility of vertical large span roll forming machines also extends to their adaptability to different materials. They can effectively work with various metals, including steel, aluminum, and copper, making them suitable for a wide range of industries. This adaptability not only increases their utility but also positions them as a cost-effective solution for manufacturers looking to diversify their offerings.

Maintenance of these machines is relatively straightforward, with many models designed for easy access to critical components. Regular checks and updates can prolong the lifespan of the machine and ensure that production remains smooth and uninterrupted. This reliability is crucial for businesses that rely on continuous output to meet customer demands.

In conclusion, the vertical large span roll forming machine represents a significant advancement in the metal fabrication sector. Its ability to produce large and complex profiles with precision and efficiency addresses the growing needs of various industries. With its automation capabilities, versatility of materials, and ease of maintenance, this machine is poised to play a crucial role in shaping the future of metal manufacturing. As technologies continue to evolve, the vertical large span roll forming machine will undoubtedly remain at the forefront, driving innovation and enhancing productivity in metal fabrication.