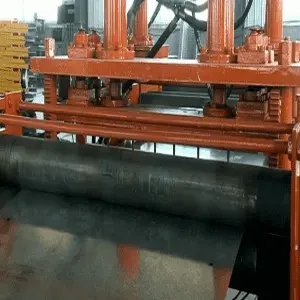

The Roof Sheet Bending Machine Revolutionizing Metal Fabrication

In the realm of metal fabrication, the roof sheet bending machine has emerged as an essential tool, streamlining the process of producing aesthetically pleasing and functional roof sheets. This machine is designed specifically for bending metal sheets, typically composed of steel or aluminum, into various shapes and profiles that are crucial for roofing applications. As construction projects evolve, the demand for precise and efficient manufacturing processes has made the roof sheet bending machine a vital piece of equipment in the industry.

Understanding the Functionality

At its core, the roof sheet bending machine operates by utilizing hydraulic or mechanical force to manipulate metal sheets into desired configurations. The process begins with feeding a flat sheet into the machine, where it is securely positioned. The operator then selects the appropriate bending parameters, which can be adjusted based on the material type, thickness, and specific bend angle required. Once these settings are in place, the machine applies pressure to the sheet, creating bends as specified.

Many modern roof sheet bending machines are equipped with advanced numerical control (CNC) systems, allowing for enhanced precision and repeatability. This technology enables operators to program multiple bending angles and shapes, resulting in increased productivity and a reduction in manual labor. The versatility of these machines allows them to produce various profiles such as corrugated, trapezoidal, and standing seam roofing materials, catering to the diverse needs of the construction industry.

Benefits of Using a Roof Sheet Bending Machine

1. Efficiency The automation of the bending process significantly reduces the time required to produce roof sheets. This enhanced efficiency translates to lower labor costs and faster project completion times.

2. Precision With CNC technology, bends can be created with high levels of precision, ensuring that each sheet conforms accurately to specifications. This precision minimizes waste and ensures that materials fit together seamlessly during installation.

3. Versatility These machines can handle different sizes, materials, and thicknesses, making them adaptable to various project requirements. Whether it’s a small residential roof or a large commercial structure, a roof sheet bending machine can be customized to meet the project's needs.

4. Quality The consistent production of high-quality roof sheets reduces the potential for defects, ensuring a more reliable final product. Quality control measures can be integrated into the machine's operations, allowing for real-time monitoring and adjustments as needed.

Applications in the Industry

The applications of roof sheet bending machines are vast. They are commonly used in the construction of residential homes, commercial buildings, industrial facilities, and agricultural structures. Roof sheets produced by these machines are not only crucial for roofing but also play a significant role in walls, facades, and other architectural elements.

Moreover, the rise of sustainable construction practices has led to an increased interest in metal roofing, given its durability and recyclability. This trend further emphasizes the importance of efficient bending machines in meeting the growing demand for metal roofing solutions.

Conclusion

As the construction industry continues to evolve, the roof sheet bending machine stands out as a critical innovation in metal fabrication. Its ability to produce high-quality, precise, and versatile roof sheets makes it a valuable asset for contractors and builders alike. By investing in modern bending technology, companies can enhance their operational efficiency, reduce costs, and ultimately deliver superior products to their clients. With the ongoing advancements in machinery and materials, the future of roofing technology appears bright, and the roof sheet bending machine will undoubtedly play a pivotal role in shaping that future.