High Straightness Drywall Roll Forming Machines A Key to Quality Construction

In modern construction, the use of drywall has become a standard practice due to its efficiency, versatility, and cost-effectiveness. With the increasing demand for quality drywall, the role of drywall roll forming machines has never been more critical. Among the various aspects that define the performance of these machines, the ability to achieve high straightness in the formed drywall profiles stands paramount. This article delves into the significance of high straightness drywall roll forming machines and their impact on the construction industry.

Understanding Drywall Roll Forming Machines

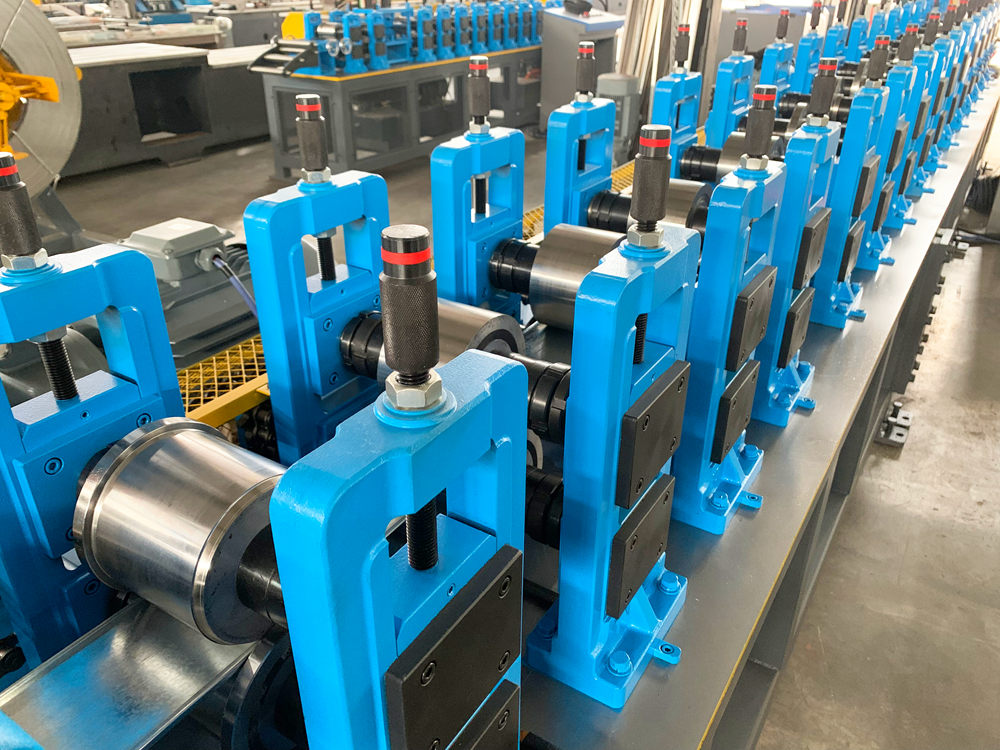

Drywall roll forming machines are specialized equipment designed to manufacture drywall profiles from raw materials such as steel or aluminum. These machines take flat metal sheets and convert them into specific shapes needed for drywall installation, including studs, tracks, and other structural components. The process involves feeding the metal sheets through a series of rollers that progressively shape the material into the desired profile, ensuring that each piece meets precise dimensional specifications.

The Importance of High Straightness

One of the key performance indicators of a drywall roll forming machine is its ability to produce profiles with high straightness. Straightness refers to the degree to which a formed piece conforms to a straight line. High straightness is crucial for several reasons

1. Structural Integrity Walls constructed with drywall profiles that are perfectly straight ensure better structural integrity. Misalignment can lead to gaps, uneven surfaces, and ultimately compromise the overall strength of the wall system.

2. Aesthetic Appeal High straightness contributes to the visual appeal of finished walls. Straight and uniform profiles result in smoother finishes and more professional-looking installations.

3. Ease of Installation When drywall profiles maintain high straightness, installation becomes more straightforward and less time-consuming. Installers can achieve perfect alignment with less effort, reducing labor costs and improving efficiency.

4. Compatibility with Other Building Materials Straight profiles are essential when integrating other building materials such as insulation, plumbing, and electrical systems. Properly aligned drywall profiles facilitate more seamless installations of these components.

Achieving High Straightness in Roll Forming Machines

For manufacturers looking to produce high-quality drywall profiles, investing in advanced roll forming machines is essential. Key features that contribute to high straightness include

- Precision Engineering Modern drywall roll forming machines utilize advanced engineering techniques and high-precision components to ensure consistent results. High-quality rollers, bearings, and guides are vital for maintaining alignment throughout the forming process.

- Automated Controls Automation plays a significant role in enhancing the accuracy of the forming process. Automated systems enable real-time monitoring and adjustments, ensuring that any deviations are corrected instantly, thus maintaining high straightness.

- Material Quality The quality of the raw materials used in the forming process also influences straightness. Manufacturers should ensure they are using high-grade steel or aluminum that can withstand the stresses involved in forming without warping or bending.

- Regular Maintenance Routine maintenance of the roll forming machine is crucial to prevent wear and tear that could lead to deviations in straightness. Scheduled inspections and timely replacements of worn parts can significantly enhance the machine's performance over its lifespan.

Conclusion

In conclusion, the advancement of drywall roll forming machines with high straightness capabilities is transforming the construction industry by enabling the production of superior drywall profiles. The benefits of high straightness, including enhanced structural integrity, aesthetic appeal, and installation efficiency, underscore the importance of investing in high-quality equipment. As the demand for drywall continues to rise, manufacturers and contractors must prioritize straightness in their production processes to meet the evolving standards of modern construction. With technological advancements paving the way, high straightness drywall roll forming machines represent a critical asset for anyone invested in the building sector.