YingYee Machinery's Glazed Tile Roof Sheet Roll Forming Machine represents more than equipment - it's a complete solution including pattern design services, material selection guidance, and production optimization support. Our machines can be customized with special coating systems, automated packaging lines, and IoT monitoring capabilities for smart factory integration.

Backed by our global technical support network and continuous R&D investment, this technology enables manufacturers to command premium pricing while reducing production costs. Whether entering the metal tile market or upgrading existing capacity, our Glazed Tile Roof Sheet Roll Forming Machines deliver the perfect combination of artisanal beauty and industrial efficiency.

표준 매개변수, 기본적인 기존 기술, 성숙한 기술 및 안정적인 품질.

In the competitive world of architectural roofing solutions, aesthetics and durability must go hand-in-hand. YingYee Machinery's Glazed Tile Roof Sheet Roll Forming Machine revolutionizes metal roofing production by combining the timeless elegance of traditional tile designs with modern manufacturing precision. This advanced system transforms ordinary metal coils into stunning glazed tile profiles that offer superior weather resistance and visual appeal.

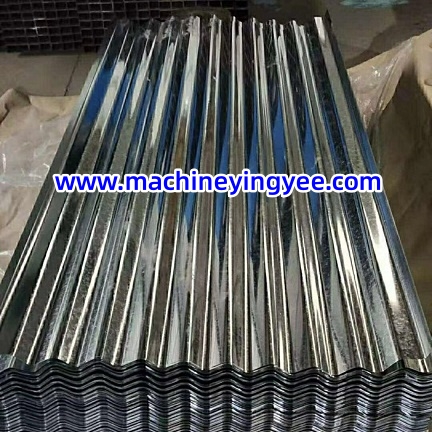

Our Glazed Tile Roof Sheet Roll Forming Machine stands out with its multi-dimensional forming technology, capable of creating authentic tile patterns with remarkable depth and texture. The precision embossing system replicates the natural look of clay tiles while maintaining the strength and lightweight advantages of metal. With production speeds reaching 15-25 meters per minute and the ability to process various materials including pre-painted galvanized steel and aluminum, this machine delivers both quality and efficiency.

For roofing manufacturers seeking to expand their product offerings, our Glazed Tile Roof Sheet Roll Forming Machine provides unparalleled competitive advantages. The machine's adaptive forming technology automatically adjusts to material variations, ensuring consistent pattern definition across every sheet. The integrated coating system (optional) can apply protective layers during the forming process, enhancing product durability.

A key innovation is our anti-scratch feeding mechanism, which preserves the pristine surface quality of pre-finished materials. The servo-controlled cutting system delivers clean, precise cuts that maintain the pattern continuity at sheet ends, crucial for professional installation. With quick-change tooling systems, manufacturers can switch between different tile patterns in under 30 minutes, enabling flexible production scheduling to meet diverse market demands.

The architectural versatility of products from our Glazed Tile Roof Sheet Roll Forming Machine continues to grow across global markets. In residential construction, these roofs provide the classic beauty of tile with the durability of metal, ideal for high-end homes and villa projects. Commercial developments increasingly specify glazed tile metal roofing for shopping centers and hotels seeking distinctive aesthetics with low maintenance.

The historical restoration sector values these products for preserving traditional appearances while upgrading to modern materials. Even religious and institutional buildings are adopting glazed tile metal roofing for its combination of dignified appearance and long-term performance. With increasing focus on sustainable construction, these lightweight metal tiles reduce structural requirements and are 100% recyclable at end-of-life.