The Evolution and Importance of Wire Mesh Making Machines

Wire mesh has become an essential material in various industries, from construction to agriculture. It provides strength, durability, and flexibility for a wide range of applications. At the heart of the production process lies the wire mesh making machine. This machinery plays a crucial role in producing high-quality wire mesh that meets the diverse needs of consumers.

Understanding Wire Mesh

Wire mesh, also known as wire cloth or wire fabric, is made from wire strands arranged in a grid-like pattern. Its specifications vary depending on gauge size, material type, and weaving techniques. Commonly used materials include stainless steel, aluminum, and galvanized steel. The properties associated with these materials, such as corrosion resistance, tensile strength, and conductivity, make wire mesh suitable for applications in filtration, fencing, construction reinforcement, and more.

The Wire Mesh Making Process

The process of making wire mesh involves several steps that require precision and advanced technology. The initial phase is wire drawing, where metal rods are pulled through a series of dies to reduce their diameter, producing wire of the desired gauge. This wire is then wound onto spools for easy handling.

Next, the weaving or welding process begins. Traditional woven wire mesh is produced using a loom, where wires are interlaced at right angles to create a grid. On the other hand, welded wire mesh is made using a machine that electronically fuses the crossing points of wire strands, resulting in a robust and uniform mesh.

After the mesh is formed, it often goes through treatments such as galvanization to enhance its resistance to rusting and improve its overall longevity. Finally, the finished wire mesh is cut to size and packaged for distribution to various sectors.

The Role of Wire Mesh Making Machines

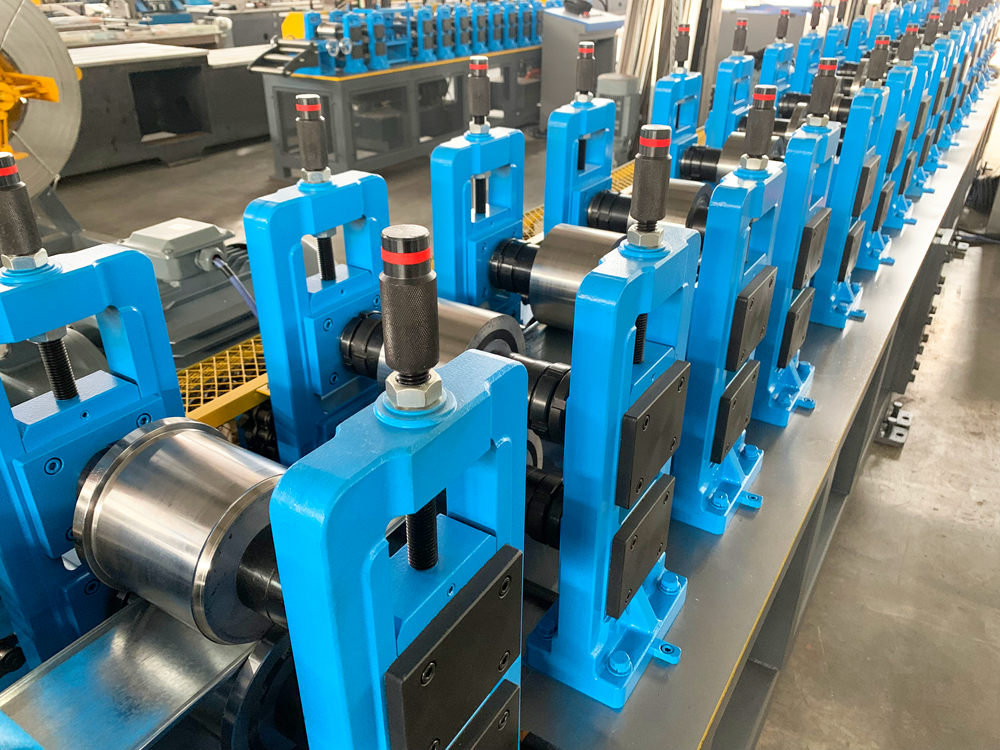

Wire mesh making machines are pivotal in automating and optimizing the production process. They have evolved significantly, incorporating advanced technologies that enhance efficiency and quality. Modern machines are capable of producing a wide range of wire mesh products at a high speed, which is vital in meeting market demand.

These machines come equipped with features such as programmable logic controllers (PLCs), automatic tension control, and precise cutting mechanisms. This automation not only reduces labor costs but also minimizes human error, leading to a higher consistency of product quality. Moreover, many machines offer adaptability to produce different mesh sizes and materials, which allows manufacturers to cater to a broader market.

Economic Impact

The wire mesh industry has a significant economic impact, as it supports various sectors including construction, agriculture, and manufacturing. Wire mesh making machines have consequently become an invaluable asset to businesses aiming to streamline production and maintain competitiveness. By investing in high-quality machines, manufacturers can ensure that they deliver reliable and durable products, thereby enhancing customer satisfaction and loyalty.

Conclusion

In summary, the wire mesh making machine is a vital component in the production of wire mesh, driving innovation and efficiency in the industry. Its advancements have allowed manufacturers to meet diverse customer needs while maintaining high standards of quality. As the demand for wire mesh continues to grow across various sectors, the importance of investing in sophisticated wire mesh making machines will only increase, shaping the future of manufacturing in this critical area. By embracing technology and innovation, the wire mesh industry can look forward to a robust and sustainable future.