Wall Angle Roll Forming Machine A Comprehensive Overview

The wall angle roll forming machine is a vital piece of equipment in the construction and manufacturing industries, known for its precision and efficiency. This machine is specifically designed to create wall angles, which are essential components in various construction applications, including drywall installation and steel framing.

Understanding Wall Angles

Wall angles are typically made from materials such as steel, aluminum, or galvanized metal. They are used to form neat and durable corners where walls meet the ceiling or where two walls intersect. The role of wall angles is crucial in ensuring that surfaces are straight and aligned, providing a solid framework for further construction or finishing work.

Functionality of the Roll Forming Machine

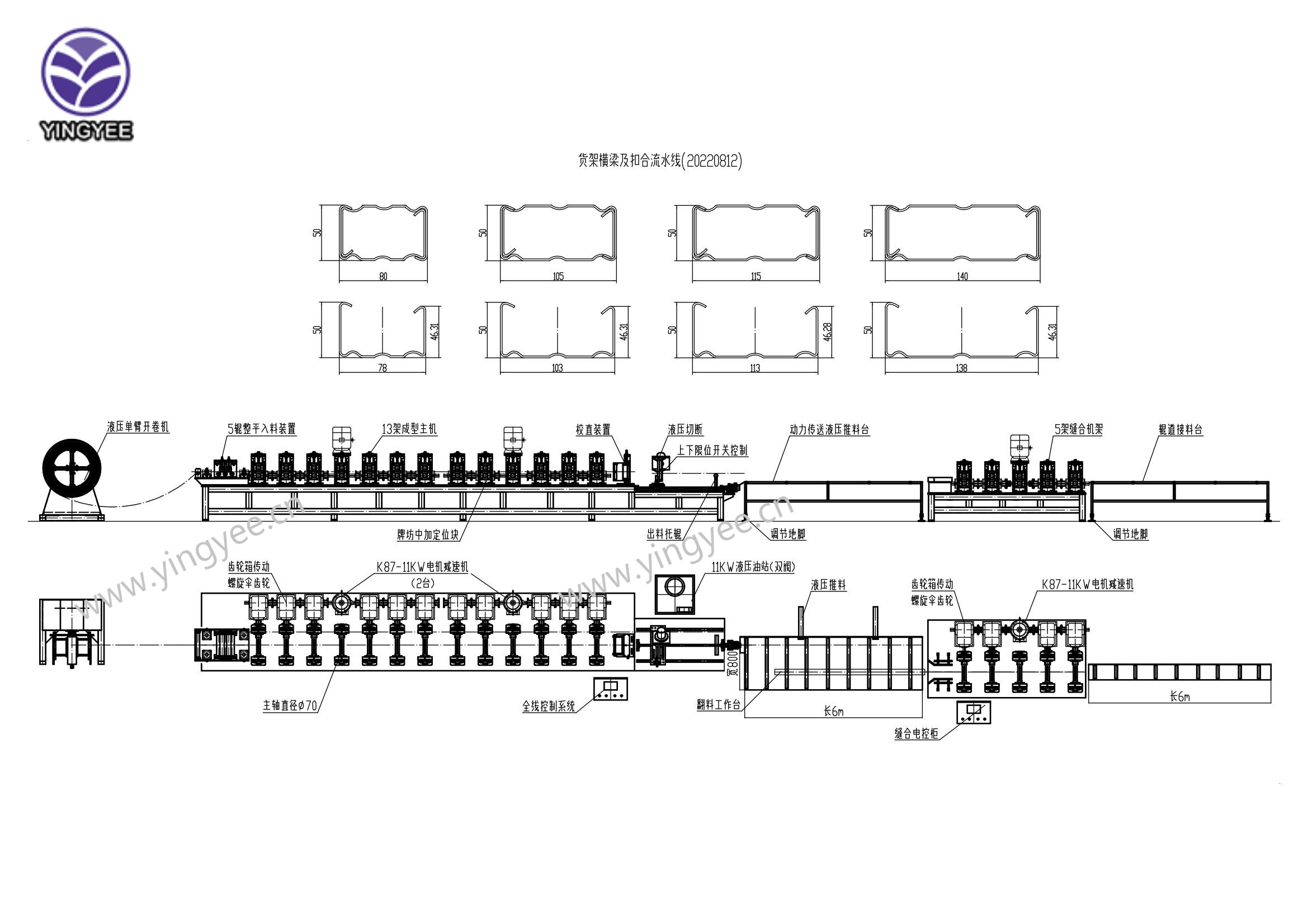

The wall angle roll forming machine operates on a straightforward principle. It takes flat metal coils and processes them through a series of rollers that gradually shape the metal into the desired wall angle profile. The machine can be adjusted to form various profiles depending on the specific requirements of a project. This versatility makes the roll forming machine a preferred choice for manufacturers needing to produce different types of wall angles.

Advantages of Using Roll Forming Machines

1. High Efficiency Roll forming machines can produce significant quantities of wall angles in a shorter amount of time compared to traditional manufacturing methods. This efficiency results in lower labor costs and faster production times.

2. Consistency and Precision The automated nature of roll forming ensures that each wall angle is produced with consistent dimensions and quality. This precision minimizes errors and waste, leading to better resource management.

3. Customization Many modern roll forming machines allow for quick adjustments to create customized profiles. This flexibility is crucial for meeting specific project requirements without needing multiple machines or extensive setup.

4. Durability Products made using roll forming are often stronger and more resilient than those produced by other methods. The continuous nature of the process enhances the material's strength, making it suitable for structural applications.

Applications in Construction

The wall angle roll forming machine is widely used across various construction projects, from residential buildings to large commercial constructions. Its capability to produce high-quality, precisely formed angles makes it an integral tool in the modern construction industry.

Conclusion

In summary, the wall angle roll forming machine plays a crucial role in the efficient production of wall angles, contributing significantly to the structural integrity and aesthetic quality of construction projects. Its benefits, including efficiency, precision, and customization, make it an invaluable asset in today’s manufacturing landscape. As technology continues to advance, we can expect further innovations in the capabilities of roll forming machines, enhancing their utility in the construction sector.