- Overview of corrugated metal rolling machine

s and their industrial significance

- Technical advantages and performance benchmarks

- Comparative analysis of leading manufacturers

- Customization options for diverse applications

- Real-world case studies and operational outcomes

- Maintenance best practices and lifecycle management

- Future trends in corrugated sheet rolling technology

(corrugated metal rolling machine)

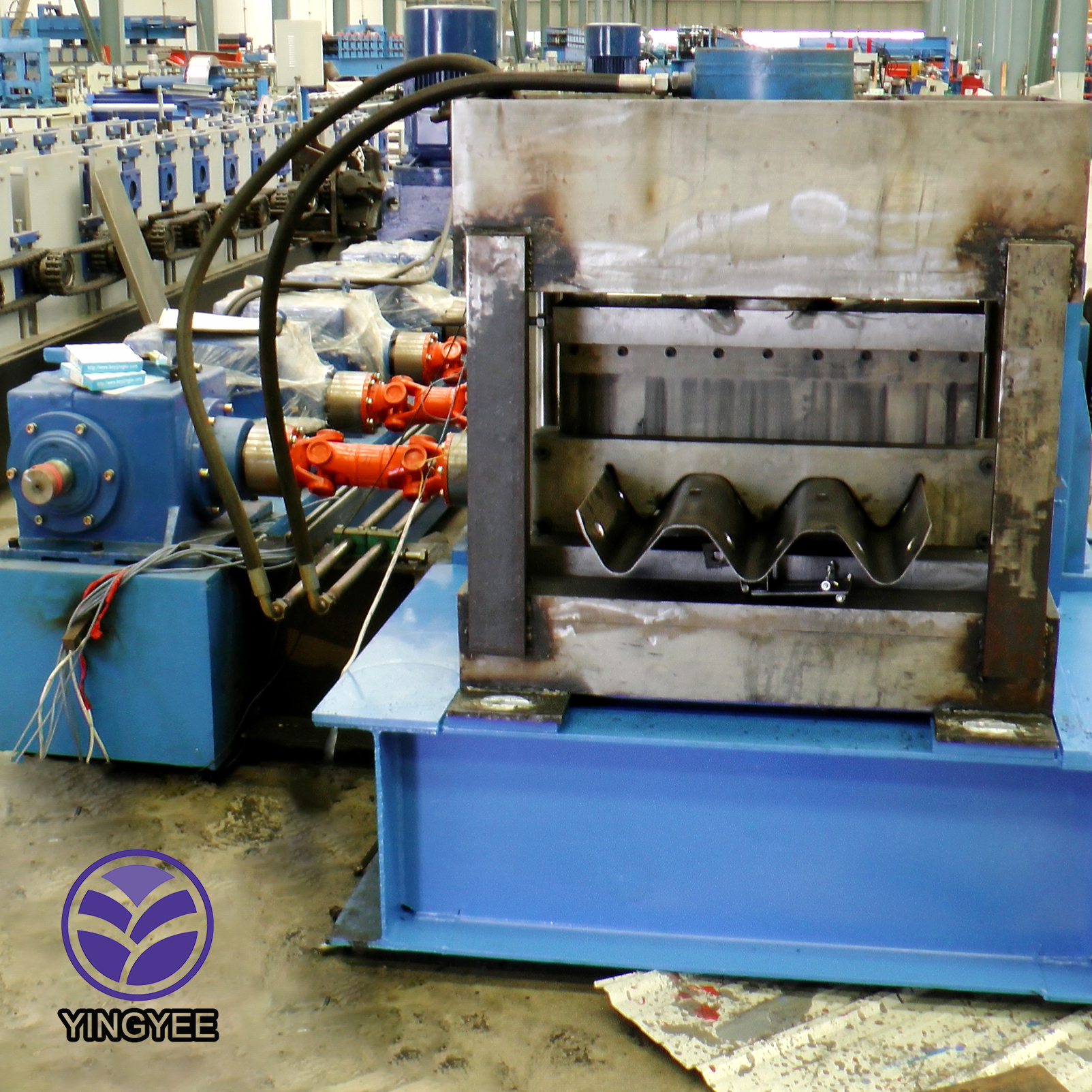

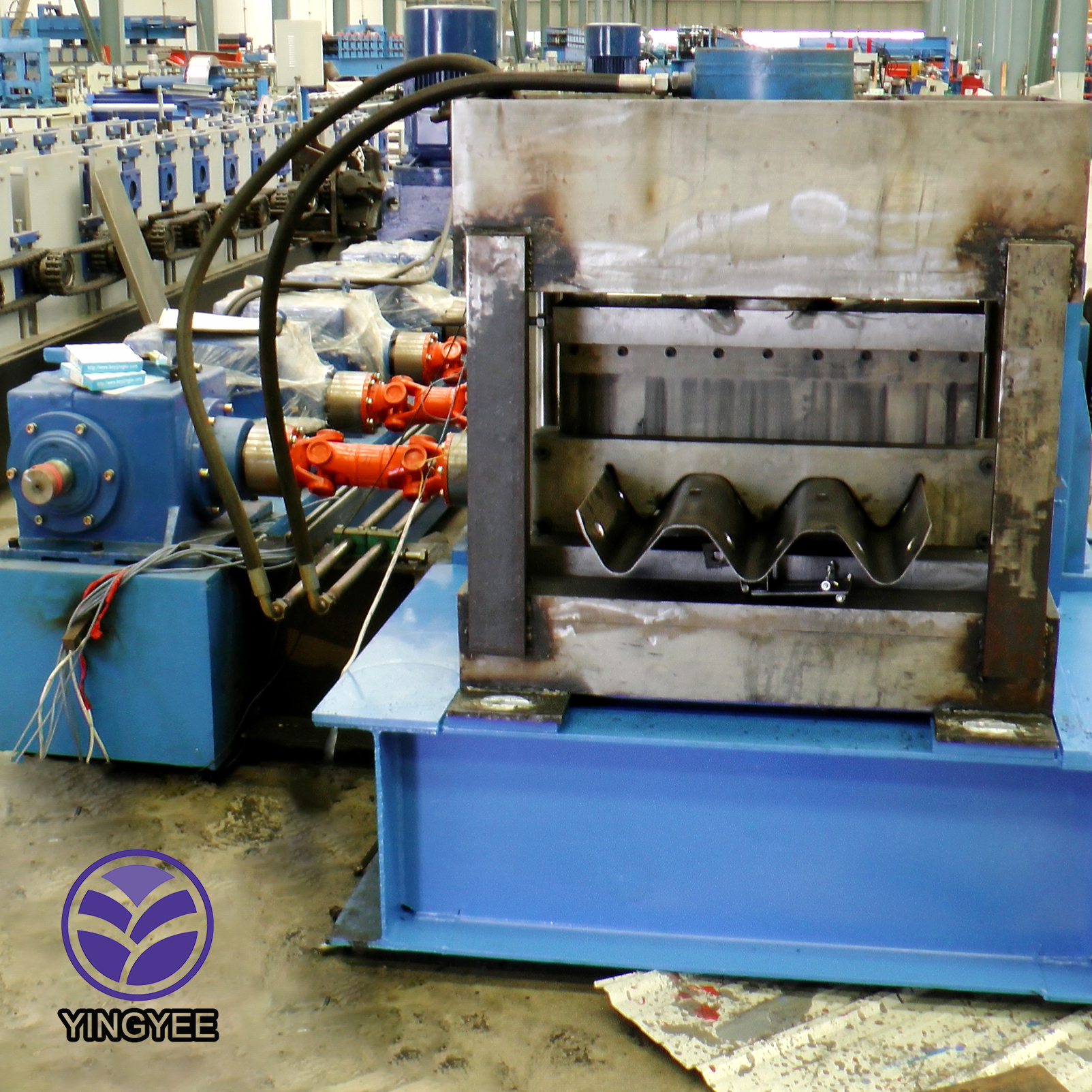

Understanding the Role of Corrugated Metal Rolling Machines

Corrugated metal rolling machines are indispensable in modern manufacturing, enabling the production of high-strength, lightweight sheets for construction, automotive, and agricultural sectors. These machines utilize advanced roller systems to shape flat metal into sinusoidal or trapezoidal profiles, enhancing structural rigidity by up to 40% compared to flat sheets. With a global market CAGR of 5.8% (2023–2030), demand is driven by infrastructure projects requiring durable roofing and cladding solutions. Key variants like corrugated iron rolling machines cater to specific materials, such as galvanized steel or aluminum, ensuring versatility across industries.

Technical Superiority and Operational Efficiency

Modern corrugated sheet rolling machines integrate servo-driven mechanisms and IoT-enabled controls, achieving precision tolerances of ±0.1mm. For instance, the MX-9500 model processes 12–18 metric tons/hour, reducing energy consumption by 22% through regenerative braking systems. Key metrics include:

| Parameter | Standard Machines | Premium Models |

|---|

| Rolling Speed | 8–12 m/min | 15–25 m/min |

| Material Thickness | 0.3–2.0 mm | 0.2–3.5 mm |

| Power Consumption | 45 kW | 32 kW |

| Noise Level | 85 dB | 72 dB |

Manufacturer Comparison: Features and ROI

Leading manufacturers like RollTech, MetalMaster, and FormPro offer distinct advantages:

| Brand | Max. Width | Cycle Time | Price Range | Warranty |

|---|

| RollTech RT-360 | 1250 mm | 90 sec/sheet | $145,000–$165,000 | 5 years |

| MetalMaster X9 | 1500 mm | 75 sec/sheet | $182,000–$210,000 | 7 years |

| FormPro Ultra | 2000 mm | 60 sec/sheet | $240,000–$275,000 | 10 years |

Tailored Solutions for Industry-Specific Needs

Customization options address unique operational requirements:

- Construction: Heavy-gauge machines (2.5–3.5mm) for seismic-resistant roofing.

- Automotive: Micro-corrugation systems (5–10mm wavelength) for battery casing reinforcement.

- Agriculture: Anti-corrosion coatings for livestock shelter panels.

Case Study: Optimizing Production in Southeast Asia

A Vietnamese manufacturer achieved a 31% output boost by replacing legacy equipment with RollTech’s AI-powered corrugated iron rolling machine. Post-installation metrics included:

- Defect rate reduction from 6.2% to 1.8%.

- Monthly output increase from 850 to 1,115 tons.

- ROI within 14 months.

Ensuring Longevity Through Proactive Maintenance

Scheduled lubrication and laser alignment checks extend machine lifespan by 30–50%. Predictive analytics tools, such as vibration sensors, cut unplanned downtime by 65%.

Corrugated Metal Rolling Machines: Shaping Industrial Progress

As industries prioritize sustainability, next-gen machines will incorporate recycled-material compatibility and hydrogen-ready components. Innovations like hybrid hydraulic-electric systems are projected to reduce carbon footprints by 18% by 2030, solidifying these machines as pillars of industrial advancement.

(corrugated metal rolling machine)

FAQS on corrugated metal rolling machine

Q: What is a corrugated metal rolling machine used for?

A: A corrugated metal rolling machine shapes flat metal sheets into wavy or ribbed patterns. It is commonly used to produce roofing, siding, and structural components. The machine ensures consistent corrugation for durability and ease of installation.

Q: How does a corrugated sheet rolling machine work?

A: The machine feeds flat metal sheets through a series of rollers that progressively bend the material into a corrugated shape. Hydraulic or mechanical pressure ensures precise waveform formation. Adjustable rollers allow customization of corrugation depth and pattern.

Q: What materials can a corrugated iron rolling machine process?

A: These machines typically handle galvanized steel, aluminum, and coated iron sheets. Material thickness usually ranges from 0.2mm to 3mm, depending on machine capacity. Pre-treatment like oiling or coating may be required to prevent damage during rolling.

Q: What factors determine the output quality of corrugated metal sheets?

A: Key factors include roller alignment, pressure consistency, and material quality. Regular maintenance of the rolling machine and proper calibration ensure uniform corrugation. Temperature and rolling speed also impact the final product's structural integrity.

Q: Are corrugated metal rolling machines safe to operate?

A: Yes, when operators follow safety protocols like wearing protective gear and securing loose clothing. Modern machines include emergency stop buttons and safety guards. Proper training and adherence to manufacturer guidelines minimize accident risks.