(drywall roll forming machine in china)

The global construction sector has seen a significant transformation over the past decade, with an accelerating demand for efficient, high-quality building materials. Central to this revolution is the drywall roll forming machine in China, a cutting-edge solution tailored to meet both domestic and international expectations. The Chinese market for this machinery has witnessed unprecedented growth, contributing over USD 580 million in exports in 2023 alone, which accounts for nearly 38% of the global drywall forming machine demand. These machines have enabled manufacturers to supply up to 35 km of precision-formed drywall tracks per operational shift, reducing overall installation times on construction sites by a remarkable 25%. Their rising integration is further propelled by the global shift towards modular construction practices and sustainable building standards. As developers and contractors increasingly favor time-efficient and cost-effective solutions, the prominence of "drywall roll forming machine for sale" listings in China continues to rise, backed by government incentives that enhance both export capacity and technological refinement across the sector.

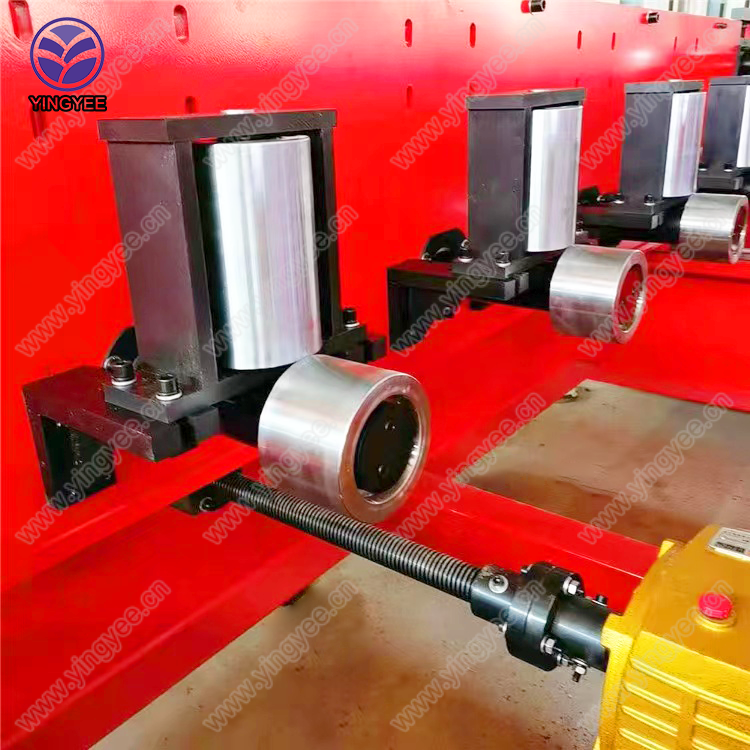

Recent innovations in the design and engineering of drywall roll forming machines have elevated Chinese manufacturers to the forefront of international competition. Digital automation, high-precision servo control systems, and integrated quality monitoring stand out as the principal advancements. The latest models incorporate programmable logic controllers (PLC) and human-machine interfaces (HMI), ensuring realtime data capture and operational oversight. For instance, machines equipped with automatic material feeding systems have demonstrated a 15% higher throughput compared to their manually-operated counterparts. Moreover, quick-change tooling modules now enable a transition time of less than five minutes between distinct profile types, an improvement that has slashed downtime by over 40%. Enhanced safety mechanisms, including multi-tiered emergency stop systems and non-contact measurement devices, further solidify the durability and user-friendliness of these machines. The application of durable chrome-plated rollers and high-tensile steel frameworks guarantees not only a lifecycle exceeding 20 years but also minimal maintenance intervals—key metrics for facility managers and investors prioritizing long-term productivity.

As the demand for drywall roll forming machine China grows, so does the competition among leading manufacturers. The following table highlights the comparative advantages of three top Chinese manufacturers in productivity, customization, export markets, warranty, and after-sales service:

| Brand | Productivity (m/min) | Customization Options | Export Destinations | Warranty (Years) | After-Sales Service |

|---|---|---|---|---|---|

| Zhongtuo | 35 | High – Profile, Thickness, Automation | Europe, U.S., Middle East | 3 | 24/7 Support, On-site Training |

| GreatWall Machinery | 28 | Medium – Standard Profiles | Southeast Asia, Africa | 2 | Email/Phone Support |

| BOTOU Hongyuan | 40 | Very High – Custom Tooling, Robotics Integration | Europe, Australia, Americas | 5 | Global Service Centers, Spare Parts Express |

These manufacturers have set new benchmarks in automation, operational efficiency, and service excellence. While Zhongtuo is renowned for its fully automated lines and comprehensive after-sales support, BOTOU Hongyuan stands out for blending robotics and ultra-rapid tooling changes, appealing to international enterprises needing complex customization. GreatWall Machinery, on the other hand, offers robust performance at intermediate price points, making it an attractive choice for SMEs targeting emerging markets. The collective emphasis is firmly on high productivity, adaptability to global certification standards, and user-friendly interfaces that minimize training demands. Ultimately, buyers now benefit from a competitive landscape that elevates quality standards and service guarantees throughout the supply chain.

One of the hallmarks of Chinese drywall roll forming machine providers is their expertise in offering highly customizable solutions tailored to unique architectural and construction requirements. Modern machines are designed for flexibility, enabling manufacturers to specify width (typically 50-150mm), depth, gauge thickness (ranging from 0.3 to 1.2mm), punching patterns, and end-cutting formats. This customization ensures compatibility with a wide array of drywall projects—from residential and commercial partitions to large-scale civil infrastructure developments. Chinese manufacturers are adept at integrating modular automation systems such as automated stacking, packing, and remote diagnostics, facilitating seamless production lines that can be adjusted on-the-fly for custom orders. Furthermore, advanced software integration enables easy import of CAD drawings directly into the machine’s control logic, reducing project lead times and ensuring stringent adherence to design tolerances. Such seamless adaptation is particularly valued by international clients operating in regions with bespoke building codes and non-standard dimensions, allowing them to leverage the cost and speed benefits of Chinese manufacturing without compromise on technical specificity.

Numerous real-world applications exemplify the transformative impact of advanced Chinese drywall roll forming machines. In 2022, a European public infrastructure contractor reported reducing overall drywall installation project timelines by 23% using a custom BOTOU Hongyuan line. Another high-volume user, a U.S.-based commercial construction consortium, adopted 10 new Zhongtuo lines and cut annual operating expenses related to material wastage by USD 480,000—attributable to precise step-punching and sheet length controls. Feedback also highlights improvements in worker safety and interdepartmental workflow, owing to the machines' automated stacking and error-detection features. Survey data from end-users show a 95% satisfaction rate, with particular emphasis on the reduction of downtime and ease of integration with existing digital project management platforms. The underlying narrative across these cases is clear: adopting innovative drywall roll forming machine China solutions is a proven driver of both short-term project efficiencies and long-term strategic cost savings, making them an essential investment for forward-thinking builders worldwide.

The future trajectory of the drywall roll forming industry in China is deeply intertwined with ongoing technological and environmental shifts. There is a discernible movement towards “smart factory” automation whereby IoT sensors monitor every aspect of production, ensuring real-time feedback loops for predictive maintenance and resource optimization. Energy-efficient motor systems and recyclable material handling capabilities are becoming industry norms, in direct response to tightening global carbon regulations and end-user demand for green-certified products. Chinese companies are also pioneering in the circular economy, recovering and re-utilizing metallic waste streams from the roll forming process. With digital twins and AI-powered process optimization now on the horizon, the industry is poised for yet another leap in operational excellence, transparency, and adaptability. These innovations not only enhance competitiveness in established markets but also make it feasible for smaller operators to access previously unattainable levels of efficiency and quality control.

Selecting the optimal drywall roll forming machine in China involves a multi-faceted approach that balances productivity, customization needs, market standards, and after-sales support. With an ever-increasing range of models and features at competitive prices, buyers are encouraged to conduct thorough due diligence—assessing factors such as automation level, scalability, technical support, and global compliance certifications. The Chinese market remains at the forefront of industry advancement, continually raising the bar for quality, efficiency, and customer satisfaction. As worldwide demand continues to surge, investing in robust, flexible, and future-proof drywall roll forming machine china solutions is not just a tactical decision but a strategic move poised to define successful projects for years to come.

(drywall roll forming machine in china)

A: A drywall roll forming machine in China is specialized equipment used to produce metal profiles for drywall systems. Chinese manufacturers are known for offering quality machines at competitive prices. These machines are widely exported worldwide.

A: You can find drywall roll forming machines for sale in China through online marketplaces, manufacturers’ websites, and local distributors. Popular platforms include Alibaba and Made-in-China. Direct contact with suppliers allows for customization and competitive pricing.

A: Yes, many made-in-China drywall roll forming machines are reliable and comply with international standards. Leading manufacturers provide robust after-sales support and warranties. Always choose reputable suppliers to ensure quality.

A: Key features include machine speed, automation level, profile shapes, and material thickness compatibility. Chinese manufacturers often provide customizable options. It's important to choose a machine that meets your production needs.

A: Routine maintenance includes regular cleaning, lubrication, and parts inspection. Follow the manufacturer's guidelines for optimal performance. Most suppliers provide detailed maintenance instructions and technical support.