|

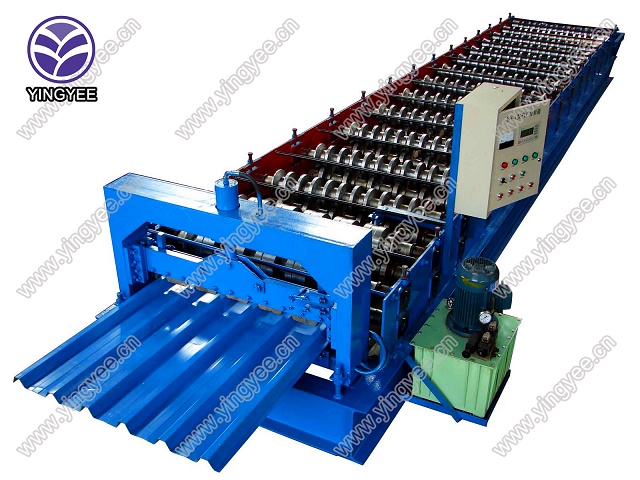

1.Matching khoom: PPGI / GI / Aluminium

2. Khoom thickness: 0.3-0.8mm

3. Lub zog: 5.5kw

4.Forming ceev: 15m / min

5.Qhov dav ntawm daim hlau: raws li cov duab kos

6.input leveling khoom: adjustable li duab.

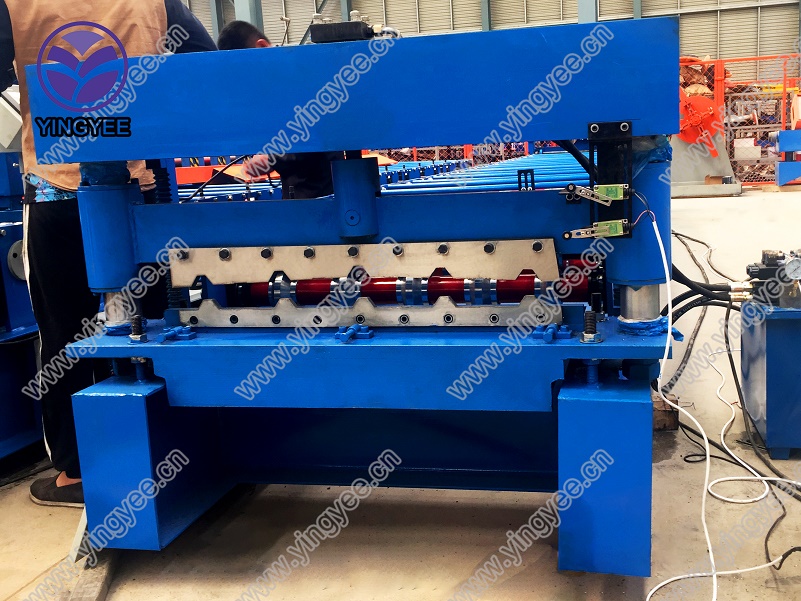

7.Rollerl chaw nres tsheb: 26 rollers

8. Ncej Khoom thiab txoj kab uas hla: materialis45 # steel ¢75mm,

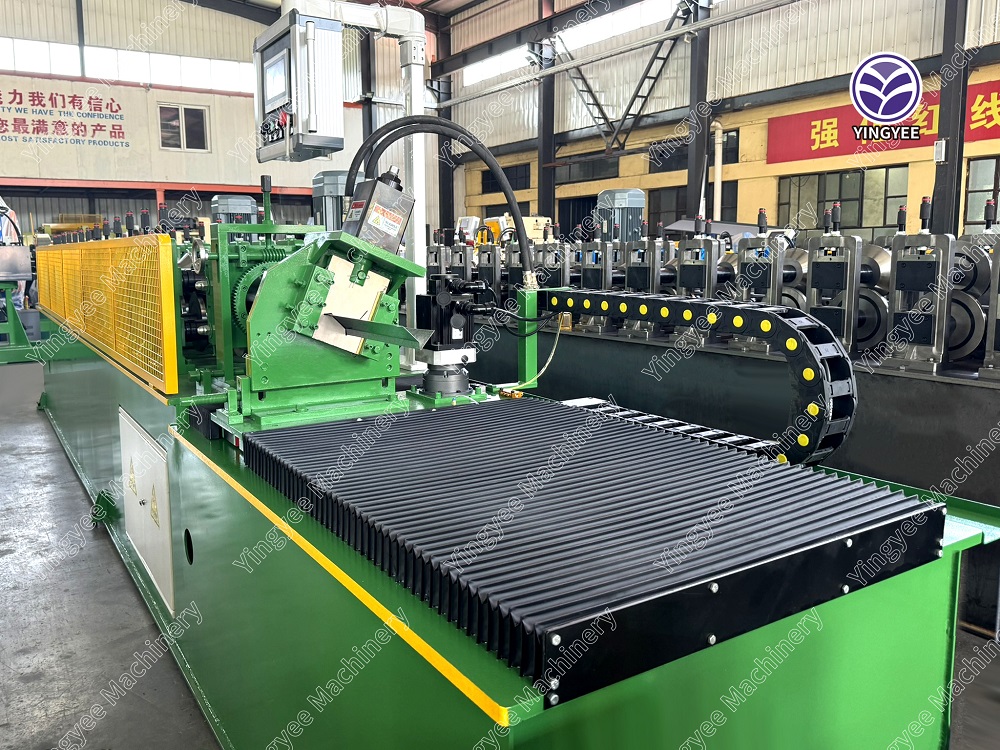

9. Kev kam rau siab: 10m ± 1.5mm

10.Txoj kev tsav: saw tsav

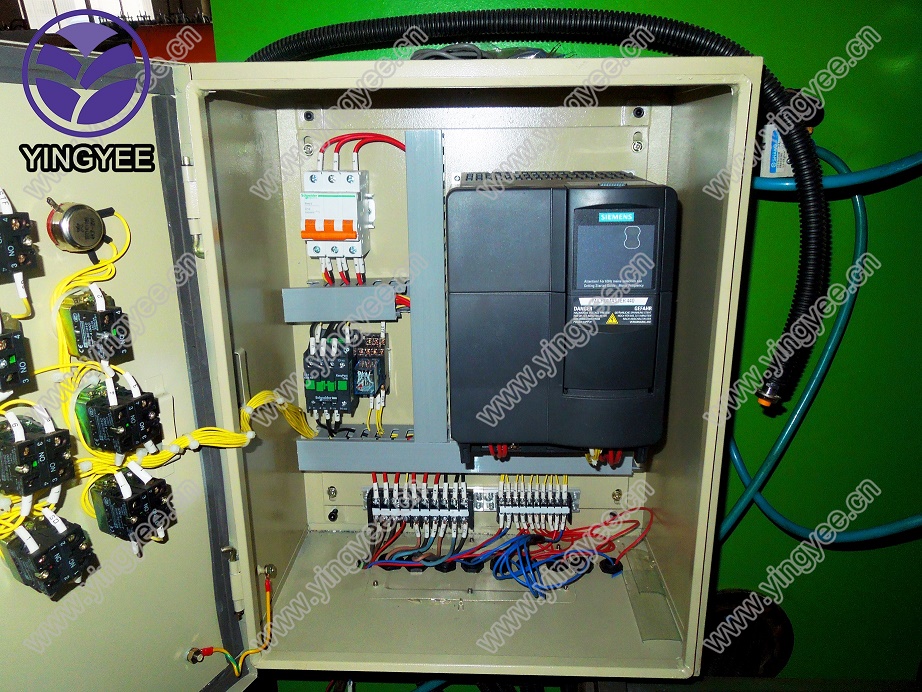

11.Controling system: PLC

12. Voltage: 380V, 50HZ, 3Phase

13.Material of forming rollers:45#steel heat treatment and chromed

14. Sab phaj: steel phaj nrog Chromed.

|