The galvanized cable tray making machine stands as a testament to modern manufacturing's evolution, offering streamlined solutions for robust cable management infrastructure. The pivotal role it plays in ensuring both the protection and organization of cables in various industrial and commercial environments cannot be overstated. This article delves into the machine's dynamic features, innovation in design, and how it enhances operational efficiency, setting a benchmark in the industry.

At the heart of this machinery lies its unparalleled precision engineering.

Each machine is meticulously crafted to ensure every galvanized cable tray produced meets stringent quality standards. The seamless production process reduces the likelihood of defects, which is vital in maintaining structural integrity and safety in its applications. The precision in manufacturing translates to significant reductions in waste, making these machines not only efficient but also environmentally sustainable.

Expertise in the development of these machines is evident through their adaptive technology. The incorporation of advanced programming and automation capabilities allows operators to customize the production according to specific project requirements. Such adaptability ensures that the cable trays produced can cater to diverse settings, whether it’s for intricate industrial setups or expansive commercial installations. Operators can modify dimensions and designs at the touch of a button, demonstrating the machine’s flexibility and user-friendly interface.

Furthermore, the galvanized coating process is a critical feature that enhances the cable tray's durability. Galvanization provides a zinc coating that protects against corrosion, a significant factor when considering the longevity of installations in environments exposed to moisture or extreme temperatures. The machine's ability to uniformly apply this coating extends the life of the cable management system, reducing maintenance costs and ensuring reliability.

In terms of authoritative standing within the industry, these machines are the product of years of research and development, with manufacturers often working closely with industry leaders and technicians to refine functionalities. This collaboration ensures that the machines not only meet current market demands but also anticipate future trends. Staying ahead of regulatory standards and industry expectations reinforces the machine’s market dominance.

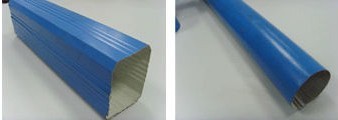

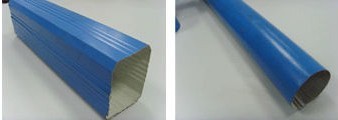

galvanized cable tray making machine

When discussing trustworthiness, it's important to highlight the rigorous testing each machine undergoes to guarantee operational excellence. Manufacturers adhere to international standards and certifications, which provide assurance to consumers about the machine’s capability and safety. This rigor in quality control is critical for building trust among users and stakeholders who rely on these machines for essential infrastructure projects.

Real-world experience further underscores the significance of these machines. Consider a large-scale data center project where efficiency and reliability are paramount. The precise construction of galvanized cable trays produced by these machines ensures optimal cable routing, reducing potential downtime and establishing a clean, organized layout for critical systems. The minimized maintenance and enhanced durability directly translate to increased uptime, underscoring the equipment’s value.

From a production standpoint, operators appreciate the ease of maintenance and operation that comes with modern galvanized cable tray making machines. Built with durable components and cutting-edge technology, downtime is minimized, and routine maintenance is straightforward. This reliability supports sustained production schedules and timely project completion, reinforcing client satisfaction and repeat business.

In conclusion, galvanized cable tray making machines embody a blend of precision, adaptability, and reliability, crucial for modern infrastructure projects. They cater to a host of applications, delivering not just efficiency but also enhanced safety and sustainability. With continuous advancements and a strong foundation of trust and expertise, these machines continue to set the standard, reshaping how industries approach cable management.