The Significance of Downspout Roll Forming Machines in Modern Construction

In the world of modern construction and architecture, the demand for efficient and precise manufacturing processes continues to rise. One of the most innovative solutions addressing this need is the downspout roll forming machine. These machines play a crucial role in the production of downspouts, which are essential components of any drainage system, ensuring that water is directed away from buildings to prevent damage. This article delves deeper into what downspout roll forming machines are, their functionality, and their importance in the construction industry.

Understanding Downspouts

Before exploring the roll forming machines, it is vital to understand the purpose of downspouts. Downspouts, also known as vertical leaders, are pipes that carry rainwater from the gutters down to the ground or to a drainage system. Properly designed and installed downspouts protect buildings from water damage by channeling rainwater efficiently. Their effectiveness relies not only on their design but also on the materials used in their construction, which is where roll forming machines come into play.

What is a Downspout Roll Forming Machine?

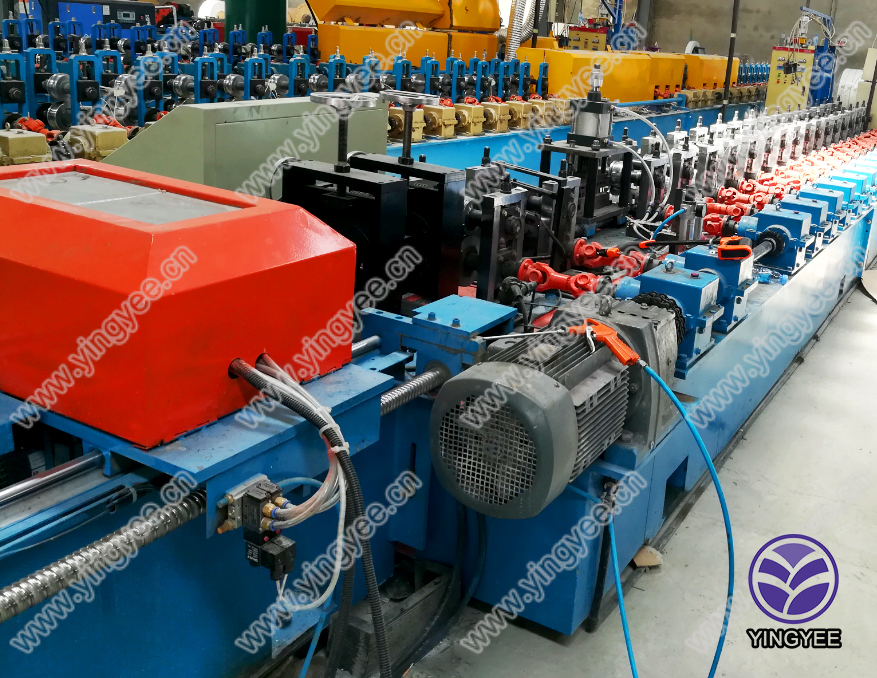

A downspout roll forming machine is an advanced piece of equipment that automatically fabricates downspouts from metal sheets. The rolling process involves feeding a flat strip of metal into the machine, which then gradually bends and shapes the strip into the desired profile. This method ensures high precision and uniformity in the dimensions of the downspouts produced. Typically used materials include aluminum and galvanized steel due to their durability and resistance to corrosion.

Key Features and Benefits

1. High Efficiency Downspout roll forming machines are designed for high production speeds. They can create a large number of downspouts in a relatively short period, meeting the demands of large construction projects without sacrificing quality.

2. Customization These machines often come with adjustable settings that allow manufacturers to customize the dimensions and shapes of downspouts according to specific project requirements. This versatility is essential in catering to the diverse architectural styles and designs found in modern buildings.

3. Cost-Effectiveness While the initial investment in a roll forming machine may be significant, the long-term savings in labor and material costs are substantial. The automation of the forming process reduces the need for manual labor, which can lower overall production costs.

4. Minimal Waste The precise nature of the roll forming process minimizes material waste, contributing to more sustainable manufacturing practices. Manufacturers can optimize their material usage, which is an important consideration given the increasing emphasis on sustainability in construction.

5. Quality Control With advanced technology and standardized processes, downspout roll forming machines ensure consistent quality in the products. This uniformity is crucial for maintaining the integrity and reliability of drainage systems.

The Future of Downspout Manufacturing

As the construction industry continues to evolve, the role of downspout roll forming machines is only expected to grow. Innovations in technology, such as automation, IoT integration, and advanced materials, are likely to enhance the capabilities of these machines. Additionally, with an increasing focus on sustainable construction practices, manufacturers will need to adapt to provide eco-friendly solutions, such as using recycled materials.

In conclusion, downspout roll forming machines represent a vital advancement in the manufacturing of drainage components. Their ability to produce high-quality, customizable downspouts efficiently and sustainably underscores their importance in modern construction. As technology continues to advance, these machines will undoubtedly play an even more significant role in ensuring that buildings remain safe and structurally sound while efficiently managing water runoff.