Tsarin Fasaha na Yanke Layin Samar da Tsawon

0.3-2*1300 cut to length line

1. Steel material: Galvanized Steel

2. Steel coil thickness: 0.3-2.0mm

3. Steel coil width: 500-1500mm

4. Max Steel coil weight: 10T

5. Steel coil I.D: 508-610mm

6. Steel coil O.D: ≤1500mm

7. line speed: 50-60m/min

8. Cutting speed:(as 1000*2000mm): 20-30 pieces/min

9. Shear length : 500-4000mm

10. Frame material: Q235

11. Voltage: 380V three-phase electricity 50Hz

12. Diagonal accuracy: ±1mm

13. Sizing accuracy: ±1mm

14. Total power: approx 70KW (Normal working power: 60KW)

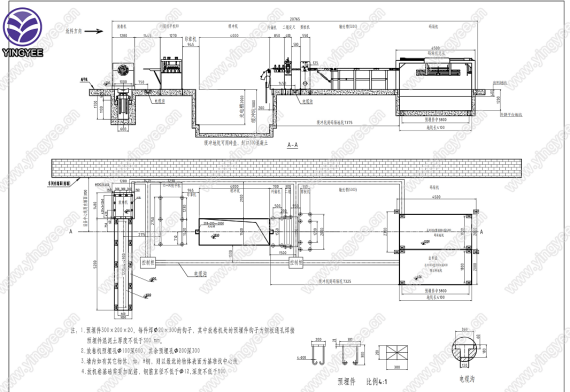

15. Unit area: Approx 23m*6m ( according to the using)

16. Unwinding direction: left to right facing the console

Injin ciki har da

1. Hydraulic single arm de-coiler with hydraulic feeding trolley

2. 15-axis dual-type precision leveling machine

3. Correction device (including trench tray)

4. Nine-roller servo sizing machine

5. Shearing machine

6. Electronic control system

7. Conveyor

8. Lifting palletizer

9. 4000mm in front of discharge platform

10. Hydraulic station

11. Fan

Zuciyar layin yanke zuwa tsayi

Na'ura mai aiki da karfin ruwa guda ɗaya de-coiler tare da trolley ciyar da ruwa

1. structure

Na'urar ita ce babban kantilever na'ura mai ba da hanya tsakanin hanyoyin sadarwa da haɓakawa, wanda ya ƙunshi babban ɓangaren shaft da ɓangaren watsawa.

(1) The main shaft part is the core part of the machine. Its four blocks are connected to the sliding sleeve through T-shaped slanting blocks and are simultaneously sleeved on the hollow spindle. The core is connected to the sliding sleeve. The fan blocks expand and contract at the same time. When the fan block shrinks, it is beneficial to roll up, and when the fan block is opened, the steel coil is tightened to complete the unwinding.

(2) The pressure roller is located behind the unwinder. The pressing arm is controlled by the oil cylinder to drive the cantilever to be pressed down and picked up. When feeding, the cantilever pressing roller is pressed to press the steel coil to prevent loosening and facilitate the feeding.(3) The transmission part is located outside the frame. The motor and reducer drive the main shaft of the unwinder through the gear to rotate, and it can also realize unwinding and rewinding.

2. Technical Parameters

(1) Steel coil width: 500mm-1500mm

(2) Steel coil weight: 10T

(3) Cylinder stroke: 600mm

Motar aiki: 2.2kw

15-axis dual-type daidaici matakin inji

1. Leveling rollers: 15

2. Leveling roller diameter: 120mm

3. Leveling roller material 45 # steel

4. Motor power: 22KW

5. The leveling effect is according to the first grade coil, except for scrap or secondary board.

6. Leveling roller material: 45 # steel.

7. After tempering, quenching and grinding, the surface hardness reaches HRC58-62, and the surface finish is Ra1.6mm.

8. The upper row of work rolls are lifted vertically by a motor drive.

9. Roller bearings are used for the work roll bearings, which have a high bearing capacity and a long service life.

Babban tsarin ƙarfi: Mota ɗaya yana motsawa a tsakiya kuma yana motsawa ta hanyar haɗin gwiwar duniya na akwatin watsawa mai ragewa.

rami

1. It uses the 2 groups of magic eyes to control the speed buffer between decoiler and slitting machines.

2. Magic eye is controlled by PLC.

3. Function: it is used to eliminate the different speed and make the plates which in wrong rail to back the right way. At first, it is used the oil cylinder to lifting the supporting and transition plates to make the head pass. When working, the transition and supporting plates lift down, the steel plates will be stored in the pit.

Correction device with Nine-roller servo sizing machine

Na'urar gyarawa:

1. Guided by vertical guide rollers. Adjust the distance between the two guide rollers manually.

2. Minimum guide width 500mm

Nine-roller servo sizing machine specifications

1. Feeding rollers: 9

2. Leveling roller diameter:120mm

3. Fixed-length roller diameter: 160mm

4. Roller material 45 # steel

Motar aiki: 11kw

Injin Shearing na huhu

Na'ura mai Shearing Pneumatic:

Ya ƙunshi ɓangarorin hagu da dama, sanduna masu haɗawa, manyan kayan aiki na sama da ƙasa, tebura, injin tuƙi, da sauransu.

(1) Maximum cutting thickness: 3mm

(2) Shearing width: 1600mm

(3) Motor power: 11KW

Mai ɗaukar bel:

Mai ɗaukar bel:

1. Belt length :7500mm

2. Width: 1450mm

Motar 2.2kw (Ikon mitar)

Mai ɗagawa palletizer

Lifting palletizer (Note: 4000mm lifting position, source of gas)

1. The blanking machine mainly carries out the blanking of the sheet, which is composed of a horizontally moving rack body and a vertical baffle.

2. The horizontal moving frame is manually adjusted according to different board widths, and the vertical baffle is adjusted according to different board lengths.

3. The stacking machine is mainly composed of stacking cylinder walking rollers and motors. Its function is to neatly stack the blanked plates.

Babban sigogi na fasaha

(1) Height of blanking rack: 2100mm

(2) Total length of blanking rack: 4300mm

(3) Total width: 2300mm

Kayan aiki mai ɗaukar nauyi: 10000kg

Ƙarin hotuna na tunani:

Ayyukanmu:

Hotunan loda inji:

Layin tsaga, wanda kuma aka sani da layin samarwa, ana amfani da shi don decoiler, slitting, da mayar da coils na ƙarfe cikin filaye na faɗin da ake buƙata. Gudun yana da sauri sosai kuma ƙarfin samarwa yana da girma. Idan aka kwatanta da na'ura mai ƙananan sauri, fitarwa da amfani da makamashi a lokaci guda suna da fa'ida a bayyane. Babban motar DC, yana da tsawon rayuwa da aiki mai ƙarfi da aminci.

Ya dace da sarrafa sanyi-birgima da zafi-birgima carbon karfe, silicon karfe, bakin karfe da daban-daban karfe kayan bayan surface shafi.