In the realm of construction and home improvement, the importance of choosing the right machinery for manufacturing roofing materials cannot be overstated. This decision not only impacts the quality of the finished product but also influences production efficiency and overall operational costs. As more businesses strive to meet increasing consumer demands while maintaining sustainability, it becomes crucial to understand the various types of roofing material machinery available and their respective benefits.

One of the primary aspects to consider when selecting roofing machinery is the type of roofing material you aim to produce. Different materials have unique requirements and challenges during manufacturing. For instance, metal roofing necessitates machinery that can handle materials such as steel, aluminum, and copper. These metals require precision cutting, bending, and sometimes even embossing to meet specific design criteria. Metal roofing machinery must be robust, durable, and capable of withstanding the demands of processing rigid materials while maintaining high accuracy and consistency.

On the other hand, if your focus is on asphalt shingles, the machinery involved will differ significantly. Asphalt shingle production involves the creation of a fiberglass mat that is later coated with asphalt and granules. Machinery in this category needs to be adept at handling this multi-layered process, ensuring each step is meticulously controlled to produce uniform and weather-resistant shingles. The machinery must offer precise control over temperature and material application rates to ensure that the shingles can endure harsh weather conditions once installed on a roof.

Clay and concrete tiles offer a more traditional aesthetic and require a distinct set of machinery capabilities. These materials are heavier and more brittle, necessitating machinery that's capable of gently handling the tiles without causing fractures or imperfections. Machinery used for clay or concrete tiles typically involves processes such as molding, pressing, and careful curing to achieve the desired look and durability.

It is not just about choosing the right type of machinery but also ensuring that it integrates seamlessly into your current production line. Automation becomes a critical component here. Automated machinery not only increases production speed but also reduces human error. With advancements in technology, many modern pieces of machinery come equipped with smart sensors and IoT capabilities that allow for real-time monitoring and adjustments. This means that potential issues can be detected and rectified before they escalate into costly downtime or quality control issues.

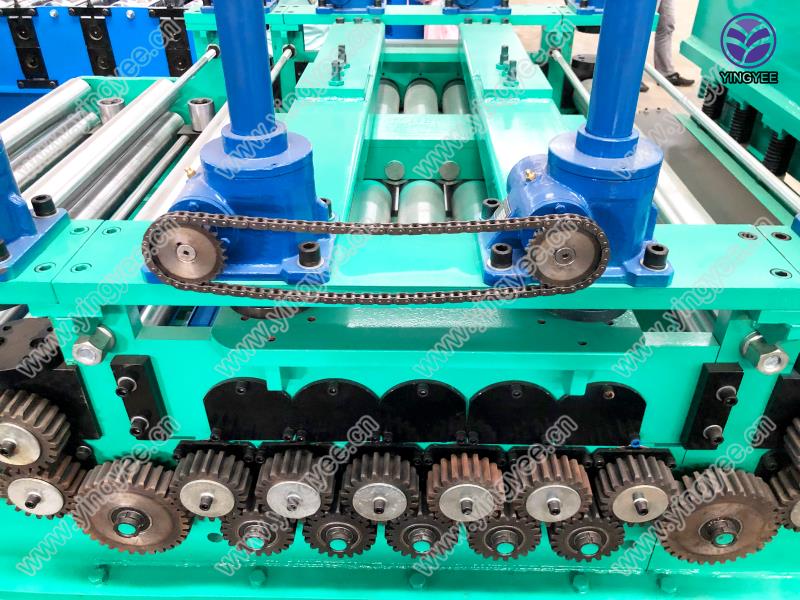

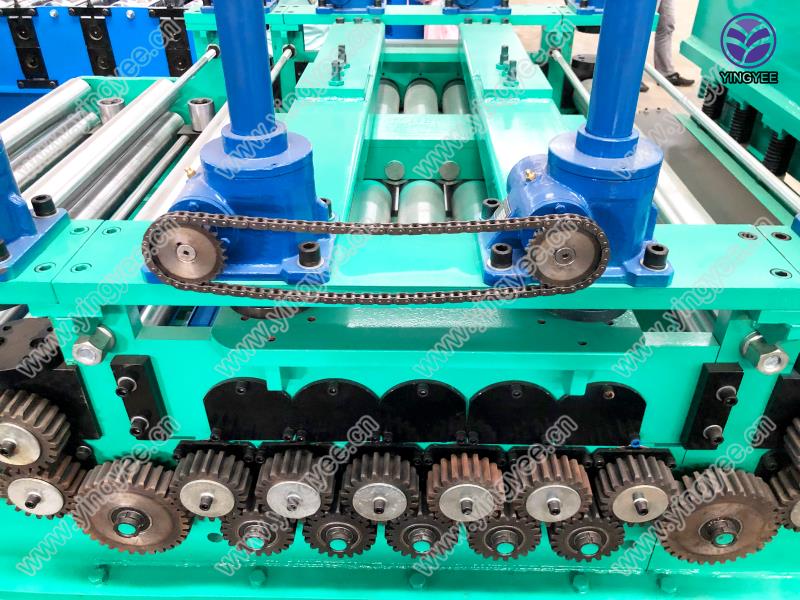

roofing material machinery

Sustainability is another pivotal factor influencing decision-making in roofing machinery. As environmental concerns take center stage globally, machinery that minimizes waste and energy consumption becomes more appealing. For example, machinery designed with energy-efficient motors and capable of recycling scrap materials can significantly reduce the environmental footprint of roofing material production. Additionally, opting for machines built from recyclable materials pays dividends both in terms of sustainability and public relations.

Furthermore, the maintenance and after-sales support of the machinery is a crucial consideration. Equipment breakdown can lead to significant financial losses due to halted production. Therefore, investing in machinery from reputable manufacturers who offer excellent customer service, easy access to spare parts, and professional maintenance is advisable. This ensures longevity and helps maintain constant production flows, meeting market demand without interruption.

Training is another critical aspect often overlooked. As machinery becomes more sophisticated, ensuring that operators are adequately trained is crucial for maintaining safety and production standards. Manufacturers that provide comprehensive training programs can enhance workforce competence, thereby optimizing the usage of the machinery to its full potential.

In conclusion, selecting the right roofing material machinery is a multi-faceted decision that requires careful examination of the material type, production capabilities, sustainability, and support services. By leveraging advanced machinery that aligns with company goals in efficiency, quality, and environmental stewardship, businesses can not only meet but exceed market expectations. This lays a solid foundation for building a reputation of reliability and excellence in the competitive roofing industry.