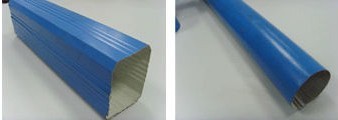

Roll forming technology has revolutionized the way truck chassis are manufactured, offering a combination of efficiency, precision, and reliability that other methods struggle to match. At its core, roll forming is a continuous bending operation in which sheet or strip metal is gradually shaped into a desired profile through a series of contoured rolls. This technique proves invaluable in producing high-strength components necessary for truck chassis, while ensuring minimal material waste and exceptional structural integrity.

One of the primary advantages of roll forming in the context of truck chassis is its capacity for high-volume production without compromising quality. The process is highly automated, ensuring consistent products that meet stringent specifications. This level of precision is crucial for truck chassis, which must endure significant stress and load without failure. Roll forming achieves this by enabling the production of complex cross-sections that enhance the structural strength of the chassis, without adding unnecessary weight.

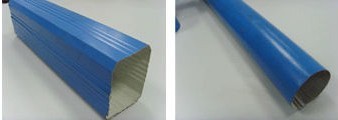

Roll forming also allows for the use of advanced high-strength steel (AHSS), which is pivotal in modern truck design. AHSS offers superior strength-to-weight ratios, which contribute to fuel efficiency—a critical consideration in reducing operational costs and environmental impact. The roll forming process is uniquely suited to shaping AHSS due to its gradual forming action, which avoids the brittleness and micro-cracking that can occur with more aggressive shaping techniques.

Experience in the industry showcases how roll forming optimizes the lifecycle performance of truck chassis. Manufacturers report that roll-formed chassis not only meet but often exceed OEM standards for durability and performance. This reliability stems from detailed process control and the careful selection of material—which, combined, enable the fine-tuning of physical properties like tensile strength and fatigue resistance.

Expertise in tool design and material science further enhances the efficacy of roll forming. Engineers leverage cutting-edge simulation software to predict the behavior of metals during the roll forming process, allowing them to preemptively address potential issues such as springback or surface defects. This predictive capability means that manufacturers can deliver parts with tight tolerances, reducing the need for secondary processing and the errors that can accompany manual interventions.

roll forming truck chassis

Authoritativeness in roll forming comes from decades of research and development, supported by industry standards and certifications that ensure each roll-formed truck chassis adheres to global safety and durability benchmarks. Companies specializing in roll forming frequently collaborate with academic institutions and research labs to push the boundaries of what's possible with this technology, continually refining processes that contribute to safer and more efficient transportation solutions.

Trustworthiness is built into the reputation of roll forming as a dependable manufacturing process. With less variability in product integrity compared to traditional stamping or welding methods, roll forming provides manufacturers with the confidence that each chassis component will perform as expected under real-world conditions. This trust is heightened by rigorous testing regimes, where prototypes and finished parts undergo cycles of physical stress simulation, ensuring compliance with both legal and environmental standards.

Incorporating roll forming in the production of truck chassis isn't just about matching a technical specification—it's about responding to the evolving demands of the modern world, where efficiency, sustainability, and reliability are paramount. As industries strive to innovate, roll forming remains at the forefront, offering a proven methodology that aligns with the future-focused needs of commercial transport.

In essence, roll forming truck chassis represents a synthesis of expertise and innovation, supported by a foundation of trust and authority. This technique not only meets the demands of today's market but is poised to adapt to the challenges of tomorrow, ensuring that trucks on the road remain robust, efficient, and environmentally sound. Whether you're a manufacturer, a fleet operator, or a logistics planner, understanding the benefits of roll forming in truck chassis production can help inform strategic decisions that enhance performance and value across the board.