The Door Frame Rolling Machine Revolutionizing Construction

In the world of construction and manufacturing, efficiency and precision are paramount. Among the various tools and machines that have evolved over the years, the door frame rolling machine has emerged as a groundbreaking innovation that transforms the way door frames are produced. This machine is designed to create robust, high-quality door frames with remarkable speed and accuracy, catering to the demands of the modern construction industry.

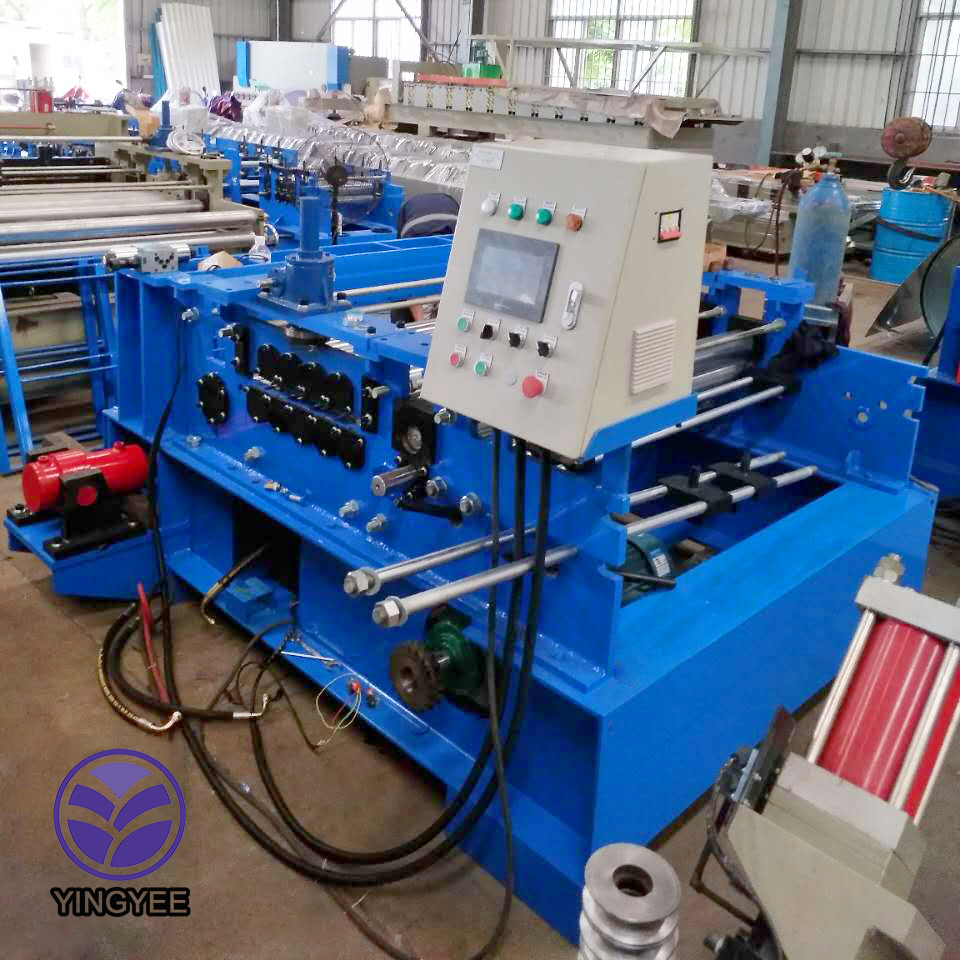

Understanding the Door Frame Rolling Machine

A door frame rolling machine is a specialized piece of equipment used to shape and form metal, typically steel or aluminum, into door frames. These machines operate through a continuous rolling process, where raw metal sheets are fed into the machine and gradually shaped into the desired profile. The end product is a strong and durable frame, perfect for both residential and commercial applications.

The machine employs a series of rollers that bend and mold the metal as it passes through. This process not only ensures consistency in the dimensions and shapes of the door frames but also significantly reduces the time required for production. The automatic nature of the rolling machine minimizes human intervention, thereby reducing labor costs and potential errors.

Key Features and Benefits

One of the standout features of door frame rolling machines is their versatility. They can be adjusted to produce various styles and sizes of door frames, making them suitable for diverse architectural requirements. Whether for standard doors, custom designs, or specific material specifications, these machines can be tailored to meet the needs of any project.

Cost-effectiveness is another significant advantage. With traditional methods of door frame production often involving multiple stages of cutting, welding, and assembly, using a rolling machine streamlines the entire process. This efficiency leads to reduced labor costs and faster turnaround times, enabling businesses to fulfill orders more rapidly and effectively.

Additionally, the quality of the door frames produced is often superior to those made through traditional methods. The precision achieved by the rolling machine ensures that the frames are uniform, structurally sound, and less prone to warping or damage over time. This quality assurance translates into enduring products that enhance customer satisfaction and brand reputation.

Applications in the Industry

The ease and efficiency of door frame rolling machines have made them an integral part of the construction and manufacturing sectors. They are widely used in creating frames for interior and exterior doors, particularly in industries where high volumes of doors are required, such as residential construction, commercial buildings, and industrial facilities.

Moreover, the ability to use a variety of materials, including galvanized steel and aluminum alloys, allows manufacturers to cater to different market segments. For instance, lightweight aluminum frames are ideal for exterior applications in humid environments, while sturdier steel frames are preferred for security doors and industrial applications.

Technological Advancements

As with many modern machines, door frame rolling machines have benefited from technological advancements, including automation and computerization. Incorporating advanced software and control systems allows for even more precise adjustments and enhanced production rates. Operators can easily switch between different frame styles with a simple change in the machine's programming, making it a highly adaptable tool in the manufacturing process.

Furthermore, the integration of smart technology facilitates real-time monitoring and diagnostics, enabling operators to identify and rectify issues promptly. This proactive approach to maintenance reduces downtime and ensures that production stays on schedule.

Conclusion

The door frame rolling machine exemplifies how technological innovation can significantly enhance production processes within the construction industry. By streamlining the manufacturing of door frames, these machines are not only improving efficiency and cost-effectiveness but also elevating the quality of the final products. As the demand for customized and durable door solutions continues to rise, the door frame rolling machine will undoubtedly play a crucial role in shaping the future of construction. Whether it is facilitating faster project completion or improving structural integrity, this machine stands as a testament to the evolution of industrial technology.