(steel slitting machine)

Global demand for steel coil slitting machines grew 7.2% YoY in 2023, driven by automotive (38%) and construction (29%) sectors. These precision systems now handle materials from 0.15mm ultrathin alloys to 14mm structural steel, achieving ±0.003mm tolerance in high-speed operations.

Modern steel strip slitting machines integrate:

Advanced models achieve 1,200 MPM cutting speeds while maintaining 99.4% material utilization rates.

| Manufacturer | Max Speed (MPM) | Thickness Range | Energy Efficiency | Price Range |

|---|---|---|---|---|

| SlitMaster Pro-X | 950 | 0.2-12mm | 3.8kW/T | $1.2M-$2.4M |

| CoilTech 8500 | 1,200 | 0.15-14mm | 2.9kW/T | $1.8M-$3.1M |

| PrecisionSlit V9 | 800 | 0.3-10mm | 4.2kW/T | $950K-$1.6M |

Leading suppliers now offer:

78% of manufacturers report 15-20% productivity gains after upgrading to current-gen systems.

Specialized configurations address:

Custom tool holders enable steel slitting machine

operators to switch profiles in 12 minutes (63% faster than legacy systems).

A European automotive supplier achieved:

This translated to $2.8M annual savings across three production lines.

Emerging steel coil slitting machines feature predictive maintenance algorithms that reduce downtime by 41%. The latest IoT-enabled models automatically adjust parameters for 97 different steel grades, ensuring optimal slit quality across variable production batches.

(steel slitting machine)

A: A steel slitting machine cuts large steel coils into narrower strips. It ensures precise width adjustments and is widely used in metal fabrication industries. This process improves material efficiency for downstream applications.

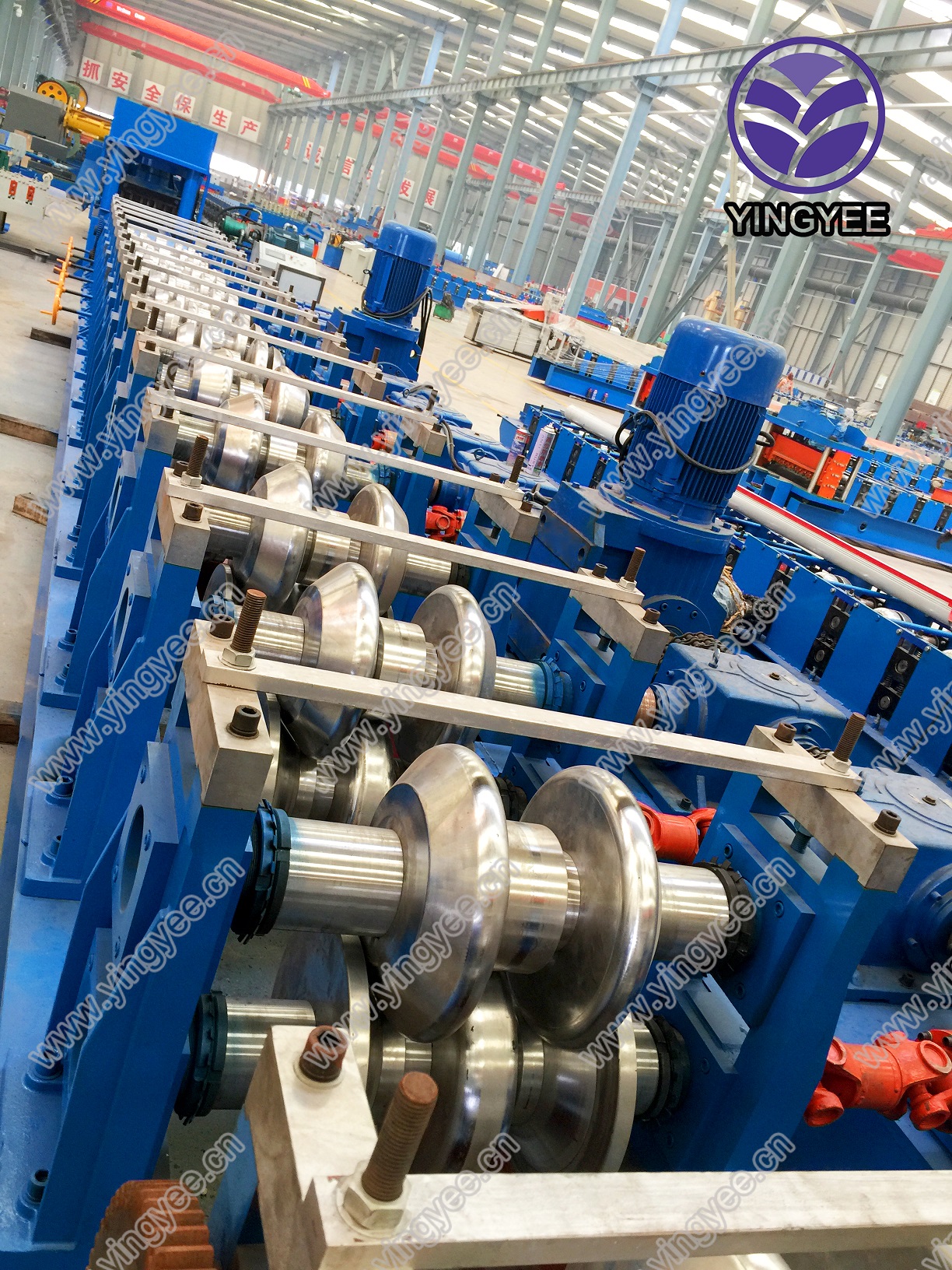

A: Key components include an uncoiler, circular slitting blades, tension stands, and a recoiler. The blades slice the steel coil into desired widths, while tension systems maintain consistency. Automated controls ensure accuracy and repeatability.

A: A steel strip slitting machine typically handles thinner or pre-cut steel strips, while coil slitters process full-width coils. Strip slitters focus on ultra-precise tolerances for specialized products. Both use similar blade technology but vary in material feed systems.

A: Automotive, construction, and appliance manufacturing rely heavily on these machines. They enable mass production of components like brackets, panels, and trim. Custom-width slitting also supports HVAC and electronics industries.

A: Regularly lubricate moving parts and inspect blades for wear. Clean debris from guides and sensors to prevent errors. Schedule calibration checks to maintain cutting precision and reduce downtime.